Bomag’s ION Dust Shield

BY AsphaltPro Staff

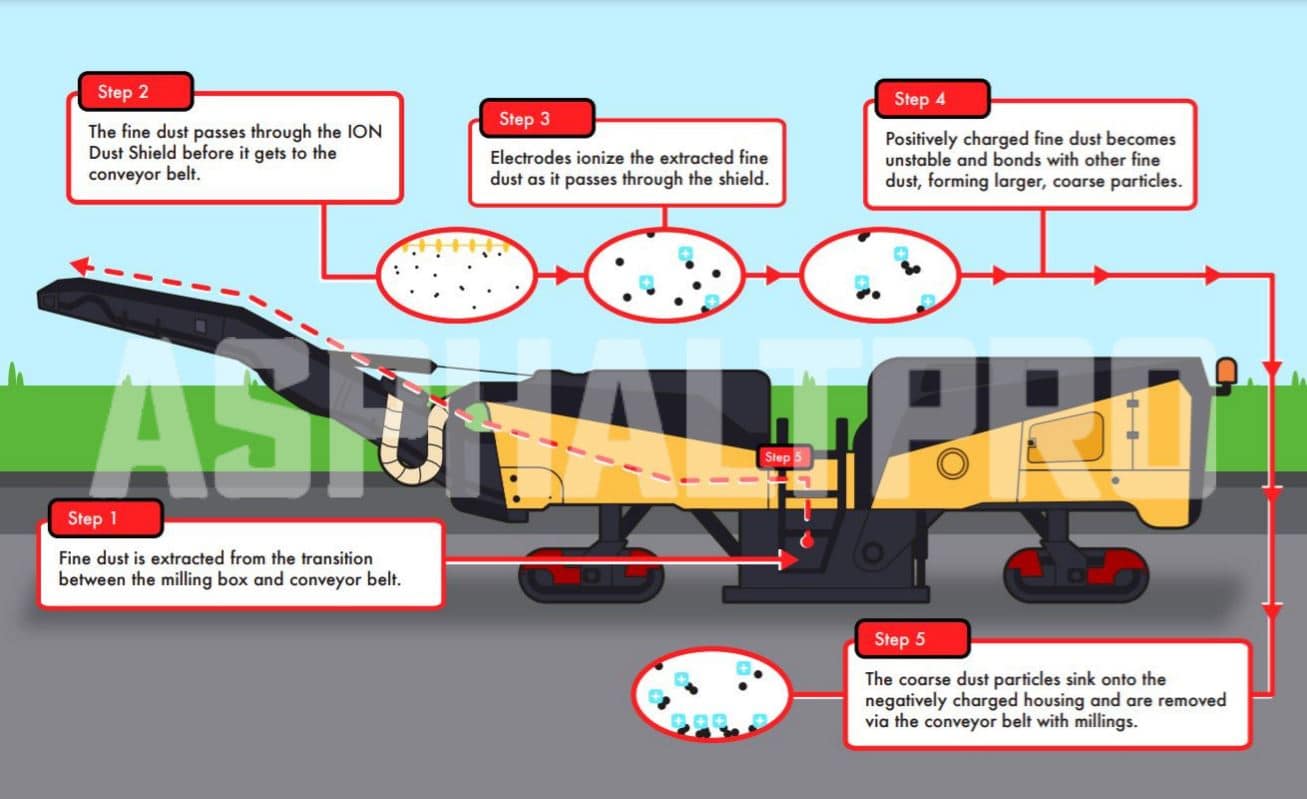

Contractors performing pavement maintenance and pavement preservation treatments strive to keep workers safe from respirable silica dust. To that end, the team at BOMAG Americas Inc., Ridgeway, South Carolina, has created a unique, patented design to not only transfer dust away from the operator(s), but also eliminate fine particles (PM 2.5, PM 10) by up to 80 percent. The ION Dust Shield positively charges fine dust particles, creating permanently bonded coarse dust. Here’s how it works:

The process begins when fine dust is created during the milling operation. While water is applied directly to the milling drum to reduce dust and cool the milling teeth, many fine dust particles pass by the water at high velocity or are too small to be captured by the water droplets.

The dust is extracted where it is generated—at the transition between the milling box and conveyor belt. A suction fan assists in pulling these particles out of the milling drum housing and into the lower conveyor. The particles are further pulled from the lower conveyor and then into the electrically charged grid of the ION Dust Shield, which is mounted onto the upper conveyor.

As the extracted fine dust particles pass through the ION Dust Shield housing and over an electrical grid, they are then positively charged.

This positive charge creates instability in the particles, causing them to bond to one another permanently. Once they become large enough that they can no longer be airborne, they fall into the negatively charged housing and are removed via the upper loading conveyor. Once on the conveyor, the coarse particles are transferred with the millings created from the milling operation as non-hazardous coarse dust. Independent studies from the Institute of Hazardous Materials Research at Rohr University have shown reduction in the emissions of fine dust particles by up to 80 percent.

For more information, visit cold planers at www.bomag.com.