Bergkamp’s SPECS

BY AsphaltPro Staff

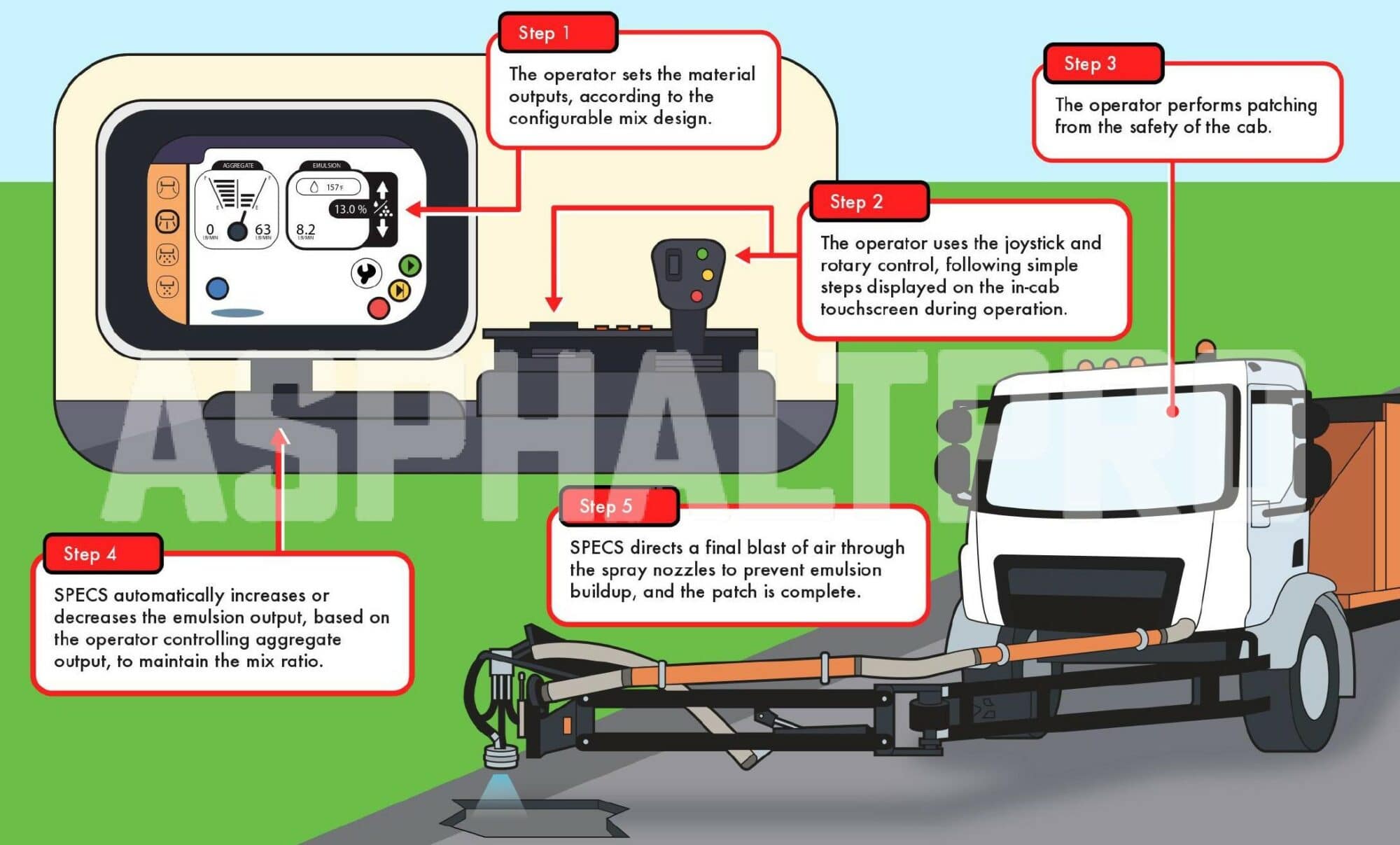

For contractors and agencies performing multiple pothole patches per day, the recently launched SP5E spray injection pothole patcher from Bergkamp Inc., Salina, Kansas, offers the ability to program the mix design and protocol for the day. Each SP5E comes with a spray-rate rotary control, joystick and touchscreen display, providing full operator command via Bergkamp’s exclusive “smart patching equipment control system” (SPECS). Here’s how it works:

SPECS is designed to allow for easy change of application and spray rate for each repair, which provides consistency across repairs each time, according to the manufacturer.

At the outset of the work shift, the operator sets the pre-determined mix design for emulsion and aggregate.

During patching, the spray-rate rotary control directly manages aggregate output and emulsion flow rate to maintain the mix ratio. The joystick controls the spray boom position, output start/stop, advance to next patch and toggle spray head oscillation. The in-cab touchscreen display provides easy-to-follow steps and all other necessary information for the operator, including temperatures, rates, modes and diagnostics.

SPECS is designed to automatically ensure rates are maintained throughout the day, which simplifies the operator’s process. And because all operations are handled via in-cab controls, SPECS also improves operator safety.

For more information, visit www.bergkampinc.com.