Bergkamp’s Pivot Tack System for the FP5 Pothole Patcher

BY AsphaltPro Staff

When spraying tack into potholes for increased adhesion, that tack can also end up sticking to equipment hoses. Hoses can also present a tripping hazard on the job site. That’s why the team at Bergkamp Inc., Salina, Kansas, engineered its new pivot tack/air hose system for its FP5 flameless all-in-one pothole patcher. Here’s how it works.

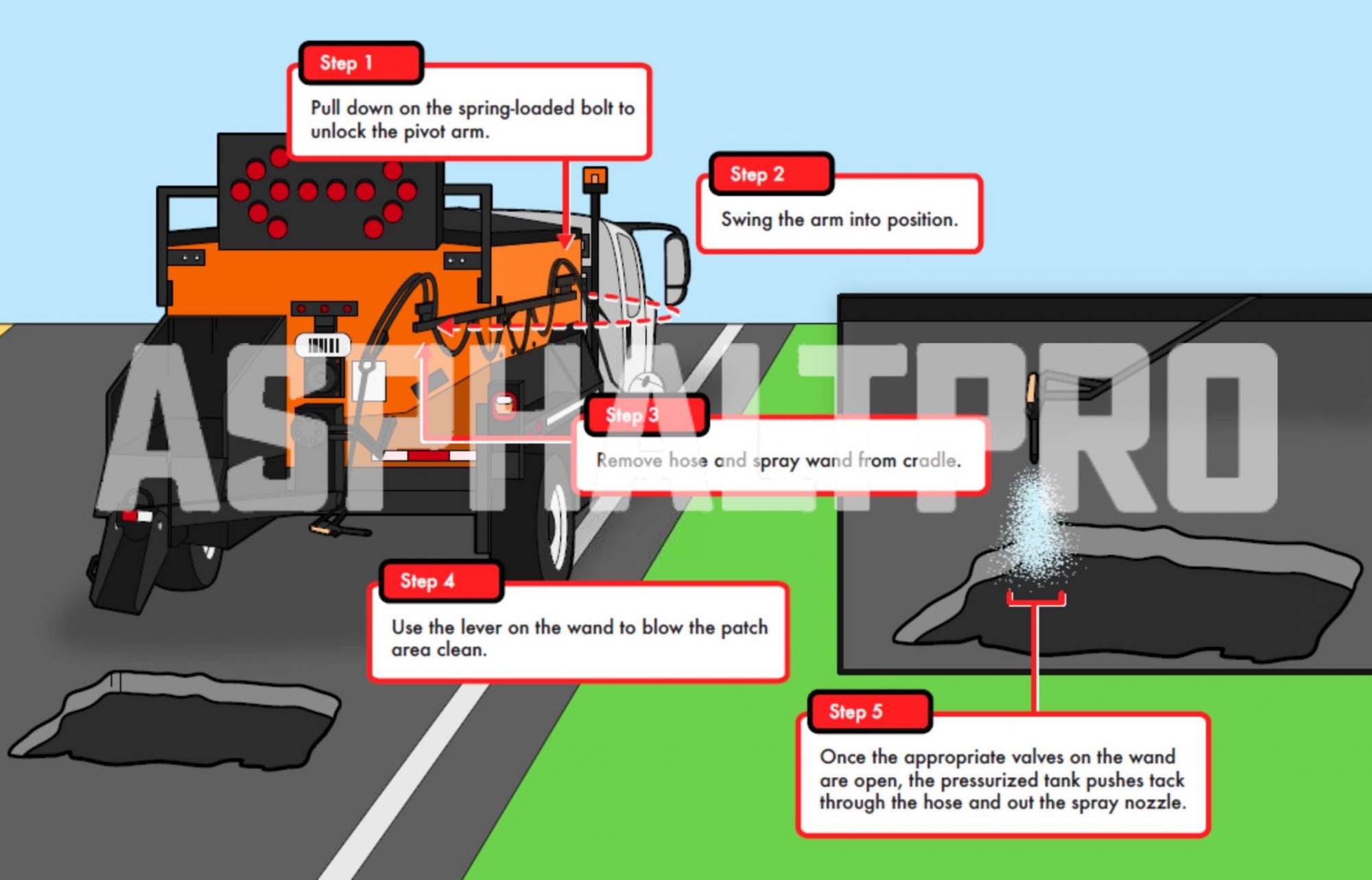

The pivoting arm, which holds the tack hose off the ground and parallel to the hopper, is located on the back right side of the FP5’s hopper body. During transportation to and from the job site, a spring-loaded bolt locks the pivot arm in the stowed position.

When the FP5 arrives to the job, the operator pulls down on the spring-loaded bolt to unlock the pivot arm and moves it into position anywhere within its 180-degree pivot range. The working distance with the hose fully extended is 20 feet from the back wall of the FP5.

Once the arm is extended, the operator uses the tack wand to blow the patch area clean of any remaining debris using compressed air. Then, he or she turns on the tack, as outlined in the OEM’s instructions, and the pressurized tank pushes the tack through the hose and out the spray nozzle. The operator will spray tack into the pothole to prepare it for patching. After tacking each pothole, the operator should depress the lever for 15 seconds to pump the remaining tack in the hose back into the tank and then wipe down any tack buildup on the nozzle.

To stow the tack wand for transport, return it to the cradle and lock the pivot arm back into position. At the end of the shift, the operator should follow the OEM’s cleaning instructions for the tack system.

The pivot arm can be retrofitted onto the FP5 pothole patcher in only a couple of hours.

For more information, contact Bryant Lovin at bryantl@bergkampinc.com.