Astec’s Fiberbed Mist Collector

BY AsphaltPro Staff

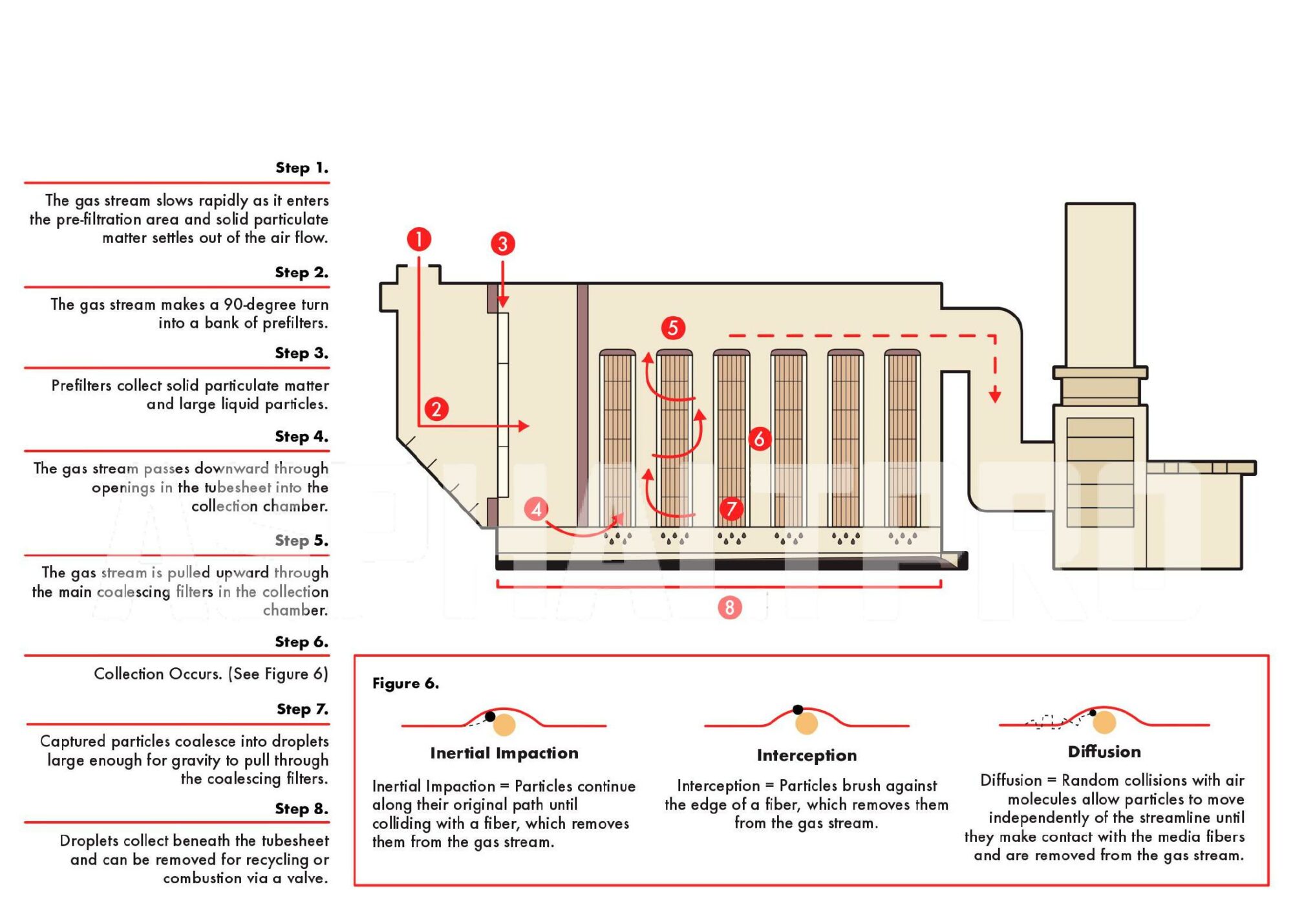

The fiberbed mist collector from Astec Industries, Chattanooga, is designed to control emission opacity by removing hydrocarbons from the incoming gas stream. Here’s how it works:

Gases enter a pre-filtration area at the inlet of the fiberbed. Here the gas stream rapidly decreases in velocity and solid particulate matter settles out of the airflow. The gas stream then makes a 90-degree turn into a bank of prefilters for further collection of solid particulate matter and large liquid particles.

After the pre-filtration compartment, the gas stream is directed downward through openings in the tubesheet into the collection chamber.

Next, the gas stream is pulled upward through the main coalescing filters where liquid droplets collect on the inner media surface. Gravity pulls accumulated droplets through the coalescing candle filters into the collection chamber. Clear air exits the fiberbed and is exhausted through a stack atop the system fan.

As the gas stream flows through the coalescing candle filters, air molecules flow around obstacles—the individual media fibers—in their paths. However, hydrocarbon particles in the 5-micron range and larger, will not. Inertia forces these large particles to continue their original path until colliding with a fiber, which removes them from the gas stream. This is referred to as impaction.

Hydrocarbon particles in the 1- to 3-micron range are collected via interception when they graze against the media fibers.

Particles below 1-micron in diameter follow the streamline as it flows between the micro-glass fibers. They exhibit random motion, which is known as Brownian diffusion. This phenomenon is due to collisions with air molecules within the gas stream. The random movements allow particles to move independently of the streamline itself. Particles tend to migrate from areas of high concentration to areas of lower concentration. Those particles that contact the media fibers are removed from the gas stream. Particle concentration near the fiber surface will go to zero thus continuing to drive the diffusion/collection process.

Captured particles coalesce into droplets, which gravity pulls through the filters to accumulate in a collection chamber located beneath the tubesheet. The bottom of the chamber slopes toward the inlet of the unit to facilitate removal of the collected hydrocarbons through a valve. The collected compounds may be recycled or combusted, as required by local regs and permit conditions.

For more information, visit www.astecindustries.com or call Catherine Sutton Choate at (423) 827-1387.