World of Asphalt/AGG1 2018 Brings Industry Innovation, Education to Houston

BY Sandy Lender

Retain What You Pay for During Training

At this year’s World of Asphalt/AGG1 conference and expo at the George R. Brown Convention Center in Houston, attendees have three days of courses from which to select education opportunities. Between the WOA’s People, Plants and Paving Conference, and AGG1’s Aggregates Academy alone, there are over 110 seminars and a couple forums/roundtables available. That means you could spend all day each day in classrooms listening to speakers help you learn new concepts or updates to tried-and-true concepts. That, my friends, is a lot of information to take in.

Back in November, Mr. T.J. Young of Duval Asphalt spoke at the Asphalt Contractors Association of Florida annual conference, and shared an intriguing concept he learned early in his career about the loads of information and education and industry knowledge we take in. His mentor taught him, “You can learn 80 percent of what you need to know in this business in about two years. It’ll take you another 20 years to get the other 20 percent.” Young referred to this as the 80/20 ratio during his presentation that day, making it clear to the audience that by training our work force to master the first 80 percent—the bulk of the knowledge necessary for quality production and quality paving—we can then drill down on the details that enhance and improve operations.

Maybe cramming the 80 percent into your brain is sufficient for you. But I think you attend, and send employees, to events such as ACAF’s conference and WOA/AGG1 to delve into the extra 20 percent.

What I think we can take away from Young’s talk in Florida is that our industry has a host of basic best practices that don’t take a long time to learn. We can get the good, solid, top quality testing, production, paving, maintenance and other practices into a new hire’s arsenal in a reasonable amount of time, and then raise expectations from there. It’s not good enough to stagnate at the 80 percent level. You send them to WOA and the like. And you want them to get the most out of the experience.

Since season shutdown, companies have flown their star employees to training centers around the country and have brought training consultants to their home offices in the name of improving quality for 2018 and beyond. Monthly sales of the Asphalt Paving 101 online course from AsphaltPro magazine have more than doubled, and OEMs offering training at their facilities report sold-out classes in the first quarter of the year. This means companies care about educating their workforces. How do you ensure the time you spend in the chair translates to better practices in the field? Now, with a course like the one from AsphaltPro, you have the option to watch the videos over and over as often as you need to. But when you get to Houston—or the OEM’s training center—you have a finite number of minutes in front of the instructor.

How do you ensure the training you engage in sticks? Let’s turn to the fields of education and healthcare for some tips and tricks to get the most out of the dollars you spend on training your employees.

A host of university and college prep sites suggest new students talk about what they’re learning, and talk about it right away. An education industry blogger, Marianne Stenger, wrote for OpenColleges that “[d]iscussing what you’ve learned, whether immediately or a few days down the line, is important because it forces you to actively process the material…whenever possible, try to participate in group discussions where you’ll have the opportunity to go over the material you’ve learned, gain new perspectives and discuss any potential misunderstandings.”

This means the 15-minute break after learning a new, complex concept isn’t necessarily the time to plan bar-hopping in Houston; it’s the time to talk about the new, complex concept. If that sounds harsh, consider who’s paying for your time in Houston. Is it the asphalt company for whom you work? Then you’re on company time in between educational sessions, just as you’d be on company time in between haul truck arrivals at the paving site; talking about improving your paving skills is not far-fetched.

Ameritech College of Healthcare listed six methods that are proven to help college students retain information. I’ll paraphrase them here:

- Teach the information to another person. By explaining a concept to someone else, you have to truly understand it yourself. (PsychoTactics.com stated “learners” retain about 90 percent of what they learn when they immediately turn around and teach it to someone else.)

- Learn/train during the time when you are most alert. This means you get in tune with the times of day when you’re at your best.

- Focus on one topic at a time. This means multi-tasking isn’t always the best option when trying to learn something new.

- Take time to learn bits and pieces, rather than rushing through reams of material.

- Write down notes. The tactile experience will help you kick different parts of your brain into gear. You can also read aloud or repeat a concept out loud—see method #1 above—to engage a different part of your brain.

- Personalize what you’re hearing/learning to make it more interesting to you and easier to remember.

You’ve got this perfect opportunity to meet with manufacturers on the tradeshow floor in the convention center. You’ve got this perfect opportunity to take notes and ask questions during the seminars and sessions. You’ve got this perfect opportunity to discuss and share information and new concepts so that you cram more than the base 80 percent into your brain for the upcoming season. You’ve got this.

Show Hours

Tuesday, March 6, 11 a.m. to 5 p.m.

Wednesday, March 7, 11 a.m. to 5 p.m.

Thursday March 8, 9 a.m. to 1 p.m.

Where’s My AsphaltPro Team?

Stop by Booth 3261 (in the very back of the hall) to learn about the Asphalt Paving 101 online training course or to renew your subscription to AsphaltPro magazine. We’re celebrating our 10-year anniversary, so be sure to ask what that means for you!

ACE

Booth 2624

ACE Group LLC of Willmar, Minnesota, will have equipment on display in booth 2624.

ACE Group offers chain & bar assemblies, screeds and extension plates, tracks and components, and augers for various pavers, pick up machines, material transfer machines, flowboy trailers/red river trailers, mc30/mc330. ACE Group also offers wear parts for all asphalt plant, paving and milling operations including plant drive and conveyor chains, sprockets, idlers, flights, trunnions, tires, baghouse bags, cages, motors, and gearboxes. All major wear parts are in stock and ready to ship. Ace parts are available in ACE Group’s Hardox AR450, AR500 and ACEBOND Chromium Carbide. ACE Group LLC also manufactures the RAP processing mill RAPwrangler and shaker decks.

Stop by to see the 2 x 2 shaker deck in the booth.

ADM

Booth 2636

ADM offers the EX120 portable plant to process high percentages of RAP.

Asphalt Drum Mixers Inc. of Huntertown, Indiana, will be available to discuss asphalt production in booth 2636.

ADM has been manufacturing high-quality portable and stationary asphalt plants and components since 1974. As a family-owned business, we’re strongly committed to providing exceptional service and customer support. Our quality guarantee is the cornerstone of our values. We build our full line of asphalt plants to last in even the world’s most demanding environments. ADM plants are at work providing high-quality, efficient performance in more than 45 countries on six continents. From planning and setup to service after the sale, our experienced team is dedicated to ensuring every customer has the right plant for his or her operation.

Visit our booth to learn how we can help you solve problems or improve production in your operation. Many asphalt contractors find that they can add and quickly pay off an asphalt plant due to increased profits, while existing asphalt producers can benefit from new plants or components. Every operation is different, and our team likes working with companies to determine their best setup. We’ll outline the features of our stationary and portable asphalt plants, with models ranging from 60 to 425 tph. We’ll also highlight our asphalt plant components, from baghouses to conveyors, and parts offering.

Come to the booth and ask: “How can ADM asphalt plants and components solve problems or improve profits for my operation?”

Ammann

Booth 1734

Ask about the Ammann ABP High Recycling Technology asphalt plant.

Ammann Group from Langenthal, Switzerland, will be available to discuss high RAP use and more in booth 1734.

Ammann has been in the asphalt-mixing plant business for more than 100 years. Ammann plants are known worldwide for their technology and innovative approach to recycling.

Ammann plants also are known as “good neighbors” because of reduced emissions, low sound and odor levels, and appealing aesthetics. The proprietary as1 Control System—the brains of the plant—is appreciated for its ease of use, quality and cost-saving efficiency.

Ammann experts will be available to discuss three key products: the Ammann Universal ABP HRT (High Recycling Technology) Asphalt-Mixing Plant for asphalt manufacturers who need to incorporate large proportions of RAP without sacrificing production capacity and quality; the highly mobile Ammann ACM Prime plant for those who have many small jobs in varied locations and where frequent transport is required; and the RSS 120-M Shredder, mobile machine that prepares RAP for use in an asphalt plant. The RSS 120-M is a patented crushing system to maintain desired grain sizes and reduce the fines that make RAP sticky.

Come to the booth and ask: “What separates Ammann’s HRT plant from the competition?”

Astec

Booth 3124

The latest generation of the Astec warm-mix system will be on display in booth 3124.

Astec Inc. of Chattanooga, Tennessee, will have equipment on display in booth 3124.

Astec Inc., a member of the Astec Industries Inc. family of companies, is a leading North American manufacturer of state-of-the-art asphalt plants and offers a complete line of portable, relocatable and stationary asphalt plant equipment, as well as soil remediation equipment and wood pellet plants. Equally important to the state-of-the-art technology and high quality that every Astec plant offers, is the Astec commitment to after-sales service, technical support and parts support. Service personnel are dispatched globally to support the set up and commissioning of plants, as well as, to train plant operators.

Stop by the booth to see the Astec Warm Mix System –the latest generation of the Astec warm mix system simplifies production of warm mix asphalt. Also check out Astec Controls—these controls can be supplied as retrofits for existing installations or as complete systems in a fully equipped control house.

CWMF

Booth 3548

CWMF will have information on the Dusteater at booth 3548.

CWMF Corporation from Waite Park, Minnesota, will have components on display in booth 3548.

For 30 years, CWMF Corporation has been offering portable and stationary asphalt plant equipment, parts, and service. We believe excellence is the result of focused intention, sincere effort and skilled execution. These values and our customer commitment are evident in every interaction. We’re fiercely committed to quality, but fluid and flexible in the ways we provide it.

We build long-term trusted relationships by helping our customers optimize overall plant performance and run at peak efficiency. Whenever we can offer solutions for existing equipment, we absolutely do.

Our tire suspension system and trunnion assembly will be on display in our WOA 2018 booth.

In addition, we’ll offer information about our full asphalt plant equipment product line.

Come to the booth and ask: “What do you mean when you talk about the extra mile?”

Eagle

Booth 2541

Ask about Eagle Crusher’s RapidDeploy plant.

Eagle Crusher Company Inc. from Galion, Ohio, will be available to discuss crushing and recycling in booth 2541.

Eagle Crusher Company offers a superior line of crushing and screening equipment for the toughest asphalt applications, made possible by the company’s more-than-100-year history. A pioneer in the manufacture of high volume portable crushing equipment for the recycling industry, processing concrete with the toughest, high volume, steel rebar, means Eagle Crusher can handle almost any application. Today, the company manufactures a complete line of heavy-duty impact crushers, portable crushing and screening plants, jaw crushers, hammermills, and conveyors, designed to meet producers’ needs.

Company personnel will be on hand to discuss the latest equipment Eagle Crusher has in development and the many benefits producers may look forward to in the near future. Personnel will also be available to assess asphalt producers’ particular crushing and screening applications to match the right Eagle Crusher equipment to producers’ specific asphalt needs.

Units range from the company’s newest and most highly portable plants, the RapidDeploy™ and UltraTraxx™, to the MaxRap® stationary system for crushing and precise screening of RAP on-site at an asphalt-plant facility, and many more models in between.

Come to the booth and ask: “What solutions can Eagle Crusher provide to me and my business?”

Evoquip

Booth 1858

EvoQuip of Northern Ireland will have equipment on display in booth 1858.

EvoQuip offers a comprehensive portfolio of products to address the needs of the compact crushing and screening markets in six key industries: building and construction; quarries; farming and agriculture; landscaping and gardening; asphalt and concrete crushing; and plant and tool hire. User friendliness is at the heart of the brand and as new products are developed the focus will be on simplicity, easy maintenance, fuel efficiency and ease of transport.

The Cobra 230 is the new impact crusher from EvoQuip. No matter what line of work you’re in, whether it is Construction & Demolition, Asphalt Recycling, Quarrying or Contract Crushing the Cobra 230 can enhance your profitability. The Cobra 230 Impact Crusher is a machine that provides class leading productivity, unmatched versatility and excellent fuel efficiency. The quick set up times, simple intuitive operation and ease of transport make this machine an ideal solution for all applications.

Come to the booth and ask: “How can compact crushing and screening benefit me and my business?”

Gencor

Booth 1624

The Idaho Materials plant in Twin Falls uses Gencor products, Gencor technology.

Gencor Industries Inc. of Orlando, Florida, will have equipment on display in booth 1624.

Gencor Industries is a leading manufacturer of asphalt plants for the construction industry. For over a century, Gencor has remained at the forefront in pioneering revolutionary innovations in asphalt plant technology. Gencor’s green products provide the industry maximum recycle and warm-mix production capability coupled with unmatched fuel efficiency.

Come to the booth and ask about Gencor’s asphalt plant efficiency.

Heatec

Booth 3116

Heatec offers a free assessment of your tank farm to help you with best efficiency.

Heatec Inc. of Chattanooga, Tennessee, will have equipment on display in booth 3116.

Heatec designs, builds, and installs quality asphalt heating and storage equipment, including heaters, tank farms, terminals, polymer blending systems, and emulsion plants. Our new controls help operators easily managing storage and precisely blend asphalt, polymers, or emulsions. We also do field service on new installations and existing plants, like pipe installation and repair. Heatec offers a free assessment of your tank farm to help make sure you are running smooth and efficient.

We are bringing an HC-120 heater, and an interactive controls display, including Recon monitoring system, polymer blending system, tank farm management controls and asphalt terminal controls. All the controls have been developed by Heatec.

Come to the booth and ask: “What’s new with Heatec?”

Ingevity

Booth 3518

Ingevity of North Charleston, South Carolina, will be available to discuss WMA additives in booth 3518.

Stop by to shoot some hoops amidst Evotherm’s March Madness mania. Come see some familiar Evotherm faces, shoot some free throws and three-point shots, and register to win two tickets to the Final Four NCAA men’s basketball game at San Antonio’s Alamodome.

Come to the booth and ask: “How can WMA enhance my paving experience?”

Kenco

Booth 2747

Kenco Engineering Inc. from Roseville, California, will have equipment models and parts on display in booth 2747.

Kenco Engineering designs and produces long-life wear parts for the asphalt, aggregates, recycling and road construction industries. Kenco uses a combination of unique processes and better materials to reduce overall maintenance costs and increase uptime when compared to other components. Whether you maintain front end loaders, asphalt plants, asphalt pavers, material transfer vehicles or crushers, you can count on Kenco to save you time and money.

Kenco will have in the booth: For crushing RAP at your plant, Kenco’s Tungsten Carbide Impregnated (TCI) hammers for your crusher. Our long-life hammers are available for many makes and models of popular crushers. To alleviate buildup in your drum’s mixing chamber, try Kenco’s TCI “Longhorn” cleanout tip. To alleviate wear issues with your “V” type flights, let us tell you about Kenco’s heavy duty “Alloy-K700” solution.

KM International

Booth 3916

KM International from North Branch, Michigan, will have equipment on display in booth 3916.

KM International’s innovative maintenance equipment line includes infrared asphalt heaters, asphalt hotbox reclaimers, asphalt recyclers, and crack maintenance equipment. For 35 years KM International has been a leading manufacturer in the pavement industry and continually looks to improve and upgrade equipment to help contractors perform fast, and efficient asphalt repairs. With equipment in over 45 different countries KM International is a true world leader in the industry.

KM International will be exhibiting our industry leading KM 8000T 4-ton asphalt hotbox reclaimer and the one and only KM T-2 asphalt recycler. Both pieces of equipment offer access to hotmix asphalt year round. The KM T-2 and the KM 8000T have their own unique uses and features, so make it a point to visit our booth to see what they can provide for you.

Come to the booth and ask: “How can KM International equipment make/or save me money and increase my profits?”

KPIJCI

Booth 2542

KPI-JCI and Astec Mobile Screens can discuss fractionating and screening RAP at booth 2542.

KPI-JCI and Astec Mobile Screens from Yankton, South Dakota, will have scale models on display in booth 2542.

Kolberg-Pioneer Inc. (KPI), Johnson Crushers International Inc. (JCI) and Astec Mobile Screens Inc. have led the way as manufacturers for the aggregate, mining, industrial, construction and recycling industries for over 90 years. As part of Astec Industries, we set ourselves apart by designing, manufacturing and selling innovative, productive, reliable and safe equipment for the industries we serve, coupled with unparalleled customer service. We are pleased to offer a complete line of crushing, screening, conveying, washing and classifying, and track equipment ideal for a diverse range of applications.

Our expert engineers possess the industry’s most advanced application knowledge for aggregate and RAP processing, ensuring that we will create the best solution to fit your needs. We provide custom-designed components, installation, and support. Our equipment, manufactured in state-of-the-art facilities, offers ongoing performance to keep your operation running. Through high performance crushing, screening, material handling and washing and classifying equipment, the group of Astec companies is able to improve your bottom line by improving aggregate quality and increasing RAP use.

Come to the booth and ask: “How can you increase my RAP use?”

Libra

Booth 2642

The Libra web services will be on display at booth 2642.

Libra Systems Corp. from Harleysville, Pennsylvania, will have equipment on display in booth 2642.

Libra Systems is a provider of asphalt plant automation, truck scale ticketing, and enterprise integration solutions for the asphalt and aggregate industries. With over 40 years of industry experience, Libra offers a full array of products and services to help material producers improve quality, streamline operations, access valuable management information and achieve greater profits.

Libra will showcase the following at the booth: centralized management solutions; dispatch/GPS tracking software; asphalt plant automation (batch, drum, silo loadout, cold feed control); aggregate scale ticketing/loadout; camera identification; web services; self-service kiosks; remote printer terminals; executive dashboards; and quote-to-cash modules.

Come to the booth and ask: “How can Libra help us optimize our trucking costs?”

Meeker

Booth 3810

Ask about Meeker’s 30,000-gallon asphalt tank.

Meeker Equipment Co. Inc., from Belleville, Pennsylvania, will have equipment on display in booth 3810.

Meeker Equipment operates two manufacturing facilities, one in Pennsylvania and the other in Ohio. We are the “Home Remodeler” to your asphalt plant. We improve your asphalt plant whether it be through fuel efficiencies, higher RAP capabilities or minimizing your maintenance costs to operate the machinery.

This year, we are featuring a “Camouflage” Patriot hot oil heater. It is to honor the men and women who serve in our military.

Come to the booth and ask: “Is this heater for sale?” Because it is!

Process Heating Company

Booth 2717

Process Heating Company from Seattle, Washington, will have a cutaway model on display in booth 2717.

Process Heating Company has 70 years of experience in manufacturing 100 percent-efficient Lo-Density® electric heating systems. PHCO’s low-watt density tank heating systems spread heat over a large surface area, keeping the heater’s sheath temperature decreased. This reduces damage to liquid AC and emulsions, keeps buildup/coking to a minimum in asphalt tanks and hot oil systems, and extends heater life. The drywell design allows you to remove and perform maintenance on the heating elements without draining the tank.

PHCo will have a cutaway model in its booth that demonstrates its drywell design, which houses the low-watt density heater coil inside. This design not only keeps the temperature lower on the heater’s sheath, reducing damage to the liquid being heated, but also allows maintenance and cleaning of the system without draining the tank. An all-new corporate video will illustrate for visitors how PHCo’s 100 percent-efficient electric heating systems work in asphalt tanks, hot oil systems, fuel oil preheaters and distributor trucks.

Come to the booth and ask: “Why should I spec electric heat into my plant or distributor truck?”

Pine Test Equipment Inc.

Booth 1636

Pine Test Equipment Inc. of Grove City Pennsylvania will have equipment on display in booth 1636.

Established in 1962, Pine has been manufacturing asphalt testing equipment since that time. Our products include Marshall Test Equipment, Gyratory Compactors and the AIMS Aggregate Imaging System. Pine’s products are “Built to Last” and our 24/7 telephone support keeps you up and running. “When your asphalt is on the line-Count on Pine”

Pine will have two gyratory compactors in our booth—the AFG2A and the AFGB1A Brovold unit.

Come to the booth and ask: “Why should I buy a Pine gyratory compactor?”

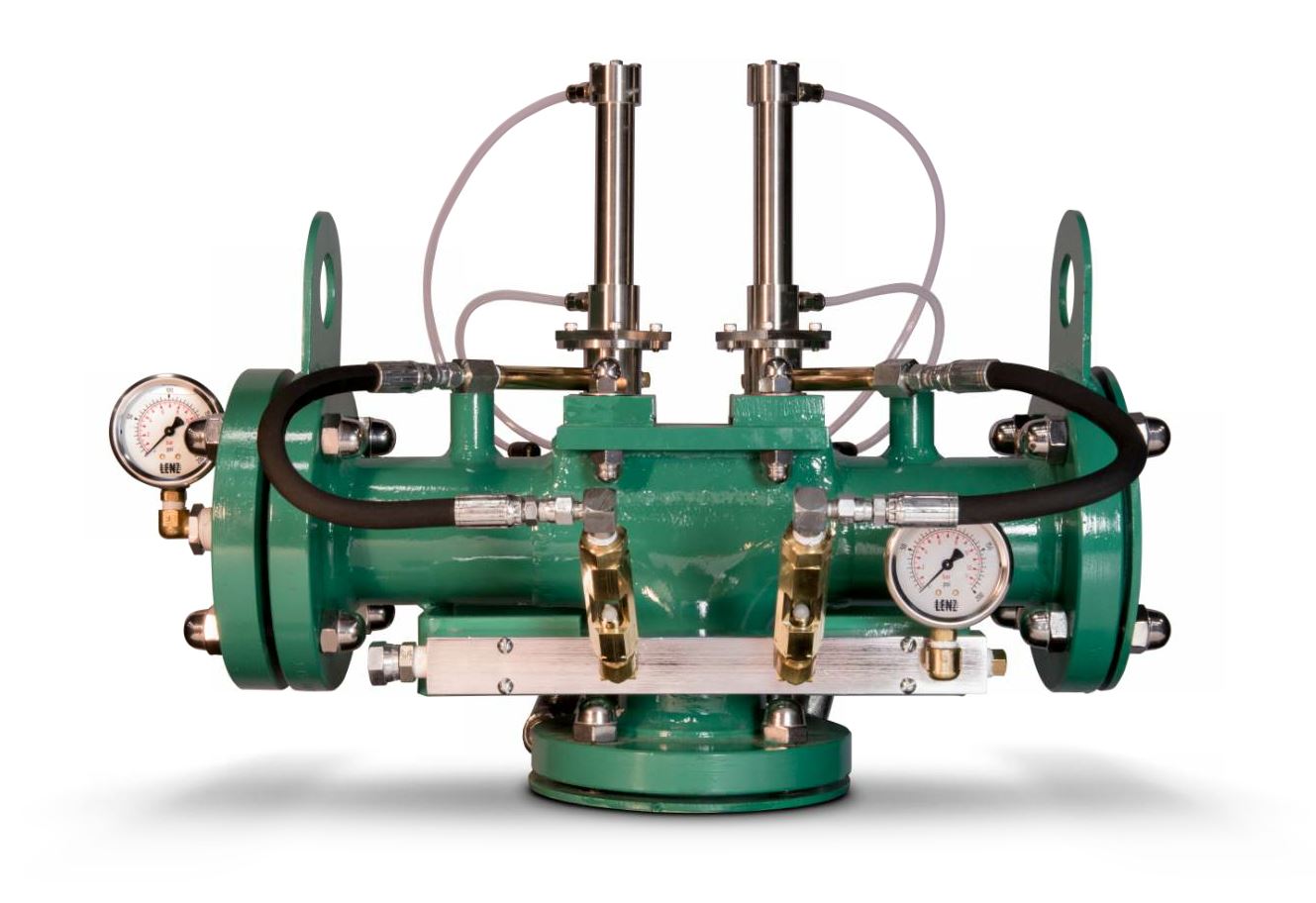

Reliable Asphalt Products

Booth 3005

Reliable Asphalt Products from Shelbyville, Kentucky, will have equipment on display in booth 3005.

Reliable Asphalt Products is a comprehensive asphalt plant equipment supplier. Reliable is a customer-driven company, and our philosophy is a basic one: provide high quality, well-built equipment and first-rate customer service. From emergency breakdowns to total plant rebuilds Reliable can assist you in any way.

The team from Reliable Asphalt Products will be displaying a Burke 2.0 hot oil heater, as well as a 3-inch asphalt pump metering skid, and a 4-inch unloading pump. We are also partnering with MINDS this year, and we will have a fully-simulated MINDS total plant control demonstration. In addition to our equipment, we will have parts and information about our other services. There will also be live music and giveaways.

Come to the booth and ask: “How can Reliable Asphalt Products bring value to my company?”

Road Science

Booth 4038

Road Science, a division of ArrMaz, from Tulsa, Oklahoma, will discuss asphalt modification at booth 4038.

ArrMaz’s Road Science division is a leader in the development of asphalt additives, emulsifiers, and paving and recycling system technologies for the asphalt industry worldwide. Our offerings span the entire customer value chain from producing key chemical components for asphalt refineries, terminals, emulsion plants and hot mix asphalt (HMA) plants, to providing laboratory support through our world-class American Association of State Highway and Transportation Officials (AASHTO) re:source accredited laboratory and field engineering support of pavement applications. Road Science delivers responsive, comprehensive and dependable customer support focused on helping our customers succeed.

Learn about NovaGrip®, our next-generation line of liquid anti-strips which are safer, worker-friendly, compatible with all types of modified asphalt and increases HMA workability. You’ll also receive information on the AD-here® ULTRA product line which combines a compaction aid with liquid anti-strip to make field compaction easier and faster. Familiarize yourself with our broad range of new and innovative emulsifiers formulated to provide distinct advantages and designed to meet your most challenging projects. And see how our STRATA® reflective crack relief system can work in composite pavements to protect pavement structures from reflective cracking, improving pavement serviceability and lengthening pavement life.

Come to the booth and tell us about your paving challenge.

Roadtec Inc.

Booths 2724

The Roadtec team welcomes you to booth 2724 to talk about best paving and milling success.

Roadtec Inc., Chattanooga, Tennessee, will have equipment on display in booth 2724.

We manufacture equipment so you can build and maintain the world’s roads. With decades of experience and an extensive line of state-of-the-art asphalt paving equipment, we help you achieve reliable and repeatable results. As an innovative leader in asphalt pavers, road milling machines, and soil stabilizers, as well as the revolutionary Shuttle Buggy®, we focus on attentive customer service and education to help you cost-effectively and safely pave your way to success. We are dedicated to innovative technology that helps you get the best results.

Visit Roadtec at 2724 where you will meet the industry’s most experienced asphalt paving pros. Roadtec has nearly four decades of paving and milling experience and our team of industry veterans are dedicated to your success. Come see five Roadtec machines at booth 2724. Be sure to check out the RX-600 Cold Planer, recently upgraded to include Auto Cut, the newest development that solves common yet costly issues when encountering obstacles.

Come to the booth and ask: “What makes Roadtec different?”

Stansteel/Hotmix Parts & Service

Booth 3638

Stansteel/Hotmix Parts & Service from Louisville, Kentucky, will have equipment on display in booth 3638.

Hotmix Parts and Stansteel are two of the most focused companies in the industry that can help improve your existing asphalt plant or provide complete plants and all new, used, or reconditioned components. Since many companies only buy a complete new plant every 20 to 50 years, there are hundreds of ways to improve existing hotmix asphalt plants one component and one process at a time. We offer solutions for every brand and every type of plant that’s ever been operated in North America.

The booth will feature many individual products and knowledgeable industry experts to talk about your hotmix asphalt plants, your operations and see what can be done to make them safer, more efficient, better able to produce all types of mixes, run more RAP and improve from component A through Z. There will be many products on display that have been developed in recent months and some that are emerging for the future.

Bring your plant pictures to the booth and ask: “What can we do to better our plant?”

Tarmac International

Booth 3716

Tarmac International’s asphalt plant components

Tarmac International Inc. of Lees Summit, Missouri, will have equipment models on display in booth 3716.

Tarmac is a complete plant manufacturer for hot mix asphalt plants and sand/rock/aggregate drying systems. Capacity of our plants is from 30 tons per hour to 600 tons per hour. Tarmac has installed over 150 complete plants around the world meeting stringent electrical and safety codes in Western Europe and all of North and South America.

We will have our ¼ scale model dryer at the show again this year. You can look inside and clearly see the different flight zones and Tarmac’s adjustable flights. We are also bringing our new ¼ scale baghouse model. Come by and check them out.

Come by the booth to ask us to build your next asphalt plant.

TransTech Systems Inc.

Booth 2735

The PQI is the flagship non-nuclear pavement density gauge.

TransTech Systems Inc. from Latham, New York, will have equipment on display in booth 2735.

TransTech Systems is the lead developer and manufacturer of Non-Nuclear Density Technology for asphalt and soils. The flagship product, the PQI Model 380, is the latest and greatest in asphalt density technology.

Our flagship product, the PQI, is what put TransTech Systems on the map. The PQI is our non-nuclear pavement density gauge. Precise pavement density and moisture measurement almost instantly (3 seconds). The PQI is more accurate than the nuclear gauge but without the hassle of regulatory training and certifications. There is no radiation threat with our product, which means after a day of work, just place it in your truck and you’re done. Enjoy less hassle and join the world leader and originator of non-nuclear density technology.

Come to the booth and ask: “How long has this non-nuclear technology been around for density of asphalt?”

Willow Designs LLC

Booth 2361

The Willow compactor follows immediately behind the company’s safety edge maker.

Willow Designs LLC from East Berlin, Pennsylvania, will have equipment on display in booth 2361.

Willow Designs is a company that specializes in paver attachments. Willow Designs started manufacturing their own unique notch wedge systems, which has now evolved into an entire longitudinal joint compaction process which is yielding unparalleled results. Willow Designs also developed its own safety edge systems that are built on the same platform as their superior notch wedge systems. If you can dream of a paver attachment, we can design and build it.

Come to the booth and ask to talk paving with Jerod.

Wirtgen America

Booth 1324

Wirtgen America Inc. from Antioch, Tennessee, will have equipment on display in booth 1324.

Wirtgen America Inc., Nashville, is the North American headquarters of the Wirtgen Group, the single-source marketer of technologically advanced lines of asphalt reclaiming/recycling, concrete slipform, and surface mining equipment from Wirtgen, asphalt and soil compactors from Hamm, asphalt pavers from Vögele, and construction materials processing equipment from Kleemann.

At World of Asphalt 2018 the innovative 10-foot tracked Super 2000-3i and 8-foot wheeled Super 1703-3i pavers will be displayed by Wirtgen America Inc. Also on display will be the Vögele Super 700-3i commercial paver, small to large-sized Wirtgen cold mills, and a variety of different-sized Hamm rollers, including the Hamm DV+ 90i VO-S rigid-frame, drum-steer, split-drum roller, and the North American introduction of the Hamm HD+ 90i PH hybrid power train tandem roller, combining a conventional internal combustion engine for base loads with a hydraulic accumulator for peak loads. A Kleemann Mobirex impact crusher ideal for processing RAP also will be shown.

Come to the booth and ask: “How will the paver design of the Vögele machines boost my productivity and enhance my bottom line?”