What’s New for Production

BY AsphaltPro Staff

While your plant crew works on updates, upgrades and upkeep during this downtime, take a gander at the products and services production-related OEMs have on the market to help you improve your bottom line.

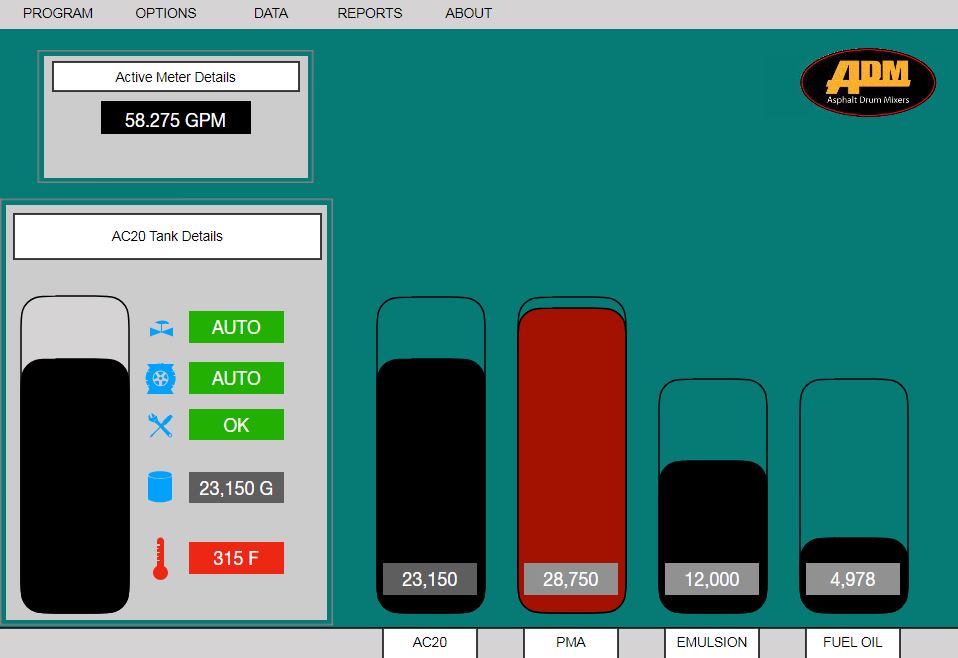

Asphalt Drum Mixers Inc.

The tank level indicator add-on from ADM

Asphalt Drum Mixers Inc., Huntertown, Indiana, offers its tank level indicator in the family of ADM Asphalt Plant Control Add-ons. The tank level indicator add-on allows plant operators to see fuel or asphalt tank levels from the control house.

“One of many available add-ons, the tank level indicator allows operators to view fuel or asphalt tank levels from the control house rather than having to walk outside to the tanks. The ability to continuously see levels from inside the control house enables operators to order material whenever necessary to keep production flowing. This is especially useful on busy days in preventing the risk of shutdowns that may result if levels fall too low because operators did not have time to visit the tanks, read levels and order the necessary material.”

For more information, call (260) 637-5729 or sales@admasphaltplants.com.

Astec Mobile Screens

Astec Mobile Screens’ ProSizer® 3600 plant

Astec Mobile Screens, Sterling, Illinois, introduced the ProSizer® 3600 plant January 2018. This plant is used to crush and screen asphalt slabs and millings for use in RAP systems.

“The ProSizer® 3600 is a single-load crushing plant for processing virgin aggregate and recycled materials. Its 36-inch x 46-inch horizontal shaft impactor can be paired with a conventional or high frequency screen. This crushing plant can be powered by diesel, electric or hybrid power. The hydraulic drive allows for variable rotor speed without loss of power, providing up to 25 percent more production over clutch-driven units, according to the manufacturer.

“This plant was designed with maintenance in mind, making equipment sustainable, even in dirty environments like recycled asphalt pavement processing. Astec Mobile Screens’ ProSizer 3600 plant also features a robust design, equipped with an I-beam frame, heavy-duty axles, and AR-lined chutes.

“An additional swing-out conveyor, with optional remote control has been added to the machine, giving producers the ability to make a third, stockpiled product. The conveyor can also be used to remove waste material that is caught in the circuit.”

For more information, contact Patrick Reaver at (815) 626-6374 or preaver@astecmmobilescreens.com.

Astec Inc.

The satellite silo system from Astec allows operators to establish a retail location away from the parent plant.

Astec Inc., Chattanooga, now offers satellite silo storage systems.

“Stand-alone mix storage systems allow operators to establish a retail location within a transportation radius of the parent plant. These storage systems enable users to expand into a location that does not yet justify a plant, while the smaller footprint of the silo system can accommodate installation at small sites that can’t support a full plant. Satellite silo system components include a truck unloading hopper (to receive mix from the trucks to fill the silos), inclined drag conveyor, long-term storage silos with anti-segregation batchers, traverse conveyors to deliver mix into the selected silo and controls.”

For more information, visit www.astecinc.com/SatelliteSilo.

Chemtek Inc.

Chemtek Inc., Research Triangle Park, North Carolina, offers the NeSilex, a silica dust suppressant designed to keep workers safe and help companies comply with new OSHA regulations.

“Respirable silica dust is deadly. When working with aggregate, concrete or in most construction activities, respirable silica dust is present. NeSilex dramatically reduces worker exposure to respirable silica dust. Simply add NeSilex to existing water systems to create a safer work space and ensure OSHA compliance.”

For more information, contact David Rigsbee at (919) 246-9021 or david@chemtek.us.

Clarence Richard

The Ez-Flo Weigh Loss Scale Controller from Clarence Richard Company

The Clarence Richard Company, Minnetonka, Minnesota, offers the Ez-Flo Weigh Loss Scale Controller. The feeder bin weigh loss scale controller is designed to upgrade a volumetric feeder control with no software changes to existing blend controls.

“Mix quality improves. 1)Tach signal is adjusted to the blend control based on the correction required as reported by the rate of bin depletion in comparison to the volumetric rate. 2) Bin bridging is reported when weigh loss is out of tolerance to what is required. 3) Low bin Level is reported. 4) Blending controls assume that volumetric rate is correct whether the bin runs empty or bridges. When running RAP and FRAP or RAS, when RAP weigh bridge changes in flow, the blending control can only assume one asphalt binder percentage. This is a problem when the asphalt binder content changes between bins. The Ez-Flo Weigh Loss Scale Controller solves these problems.”

For more information, contact David Wilken at (701) 318-6432 or david@clarencerichard.com.

ClearSpan Fabric Structures

ClearSpan offers buildings with shipping container foundations for a unique storage solution.

ClearSpan Fabric Structures, South Windsor, Connecticut, offers its ClearSpan buildings with shipping container foundation. “ClearSpan structures are versatile enough to build atop shipping containers, creating a unique foundation option and creative storage solution.”

“ClearSpan structures built on top of shipping containers provide abundant storage opportunities for the asphalt industry. These durable containers offer storage space for valuable equipment and tools, while simultaneously providing a sturdy building foundation. Customers can use an individual container on each side of the structure or stack multiple containers to provide extra clearance for taller aggregate piles and commercial equipment to fit inside. This economical foundation option allows customers to build nearly anywhere and easily transport structures to different work sites, all while avoiding the expenses associated with traditional foundation options, such as poured concrete or posts. The fabric cover offers temperature regulation and coverage from the outdoor elements, preventing piles from absorbing unnecessary excess moisture.”

For more information, call (866) 643-1010 or visit www.ClearSpan.com.

Eagle Crusher Company Inc.

The new Stealth™-500 crusher from Eagle

Eagle Crusher Company Inc., Galion, Ohio, launched the Stealth™-500 May 2018. It is an all-electric crusher and screen on one chassis.

“The highly portable Stealth™-500 features a unique, two-step, five-foot grizzly deck to allow for material that passes through the grizzly deck to be blended back with the crushed material, minimizing crusher wear. The plant’s two-deck inclined screen produces two cubical products, while top-deck retained material is returned to the crusher for further processing and higher quality production. Priced at $399,999 the Stealth is specifically configured to help cost-conscious businesses enter the asphalt, aggregate, and sand and gravel industries or economically add to their fleets for an unexpectedly low, initial investment price for a high production crushing and screening plant on one chassis.”

For more information, call (800) 253-2453 or sales@eaglecrusher.com.

Gencor Industries Inc.

The Portable Ultraplant from Gencor Industries

Gencor Industries Inc., Orlando, offers the Gencor’s Portable Ultraplant®. “Gencor’s Portable Ultraplant is a fuel efficient, environmentally clean, easy-set-up, and low-maintenance design for the hot-mix industry. A totally integrated drum concept that allows high production continuous mix with high-volume, high moisture recycle.”

“The Gencor Ultraplant® combines simple design with the most advanced control technology and massive heavy construction in the industry. Backed by world class product support and training, Gencor Portable Ultraplants provide contractors years of dependable long life with low cost- low maintenance operation for the highest profitability. Whether you’re near home or paving towards the north pole, a Gencor plant is your best choice.”

For more information, visit www.gencor.com.

GreenMantra™ Technologies

GreenMantra Technologies, Brantford, Ontario, introduces its line of Ceranovus® polymer additives.

“The Ceranovus polymer additives blend with standard low shear mixing and lower asphalt viscosity for improved processability during application.”

“Ceranovus A Series polyethylene and polypropylene polymer additives, when incorporated into asphalt at 2 percent by weight, deliver grade bumping while maintaining low temperature properties. The additives are designed to increase the penetration hardness of the asphalt and provide improved resistance to rutting and deformation.”

For more information, visit www.greenmantra.com.

Heatec Inc.

Heatec Inc., Chattanooga, offers the Recon® Monitoring System, which monitors temperatures, levels and heater status of the tank farm at your asphalt plant on a mobile device.

“The Recon monitoring systems allows you and anyone with access to the system to keep an eye on your tank farm from a smart phone, tablet or PC. The system also sends alerts via email or text if there is a problem. The latest version can uses a cellular connection or a wifi connection. The cellular connection eliminates the need to hard wire to your network and is good for plants without internet access or in remote areas.”

For more information, contact Heatec Parts at (423) 821-5200.

John Deere

John Deere, Moline, Illinois, added the new 244L and 324L models to its compact wheel loader line at the end of 2018 for ag material handling, construction and other tasks.

“Tailor-made for tight spaces, the 244L and 324L use our proprietary Articulation Plus™ system to provide greater stability and yield more lifting power while turning tighter.”

The Articulation Plus feature includes an articulated frame plus rear-wheel steer. Newly optimized linkage provides improved parallel lifting, with 6 degrees of rollback. The 244L achieves an 8-foot, 3-inch full-lift dump height and a full-turn top load of 8,157 pounds; the 324L with high lift reaches a 10-foot, 3-inch height.

For more information, visit www.JohnDeere.com.

Kenco Engineering Inc.

Kenco offers the TCI serrated cutting edge to penetrate hardened RAP piles.

Kenco Engineering Inc., Roseville, California, offers its Kenco Tungsten Carbide Impregnated (TCI) serrated cutting edge, introduced in 2016 and developed for easier penetration of hardened RAP piles without using teeth.

“Designed to give some of the benefits of teeth along with the benefits of a straight cutting edge, the Kenco serrated Tungsten Carbide Impregnated (TCI) cutting edge will penetrate old and hardened RAP piles more easily than a standard flat blade but won’t leave trenches in the yard floor the way teeth will. Though trading some overall wear life for better penetration, the Kenco serrated design still gets the benefit of our unique TCI process. Get the best of both worlds with the Kenco serrated TCI cutting edge, good penetration with good wear life.”

For more information, contact Paul McDowell at (916) 782-1796 or paul@kencoengineering.com.

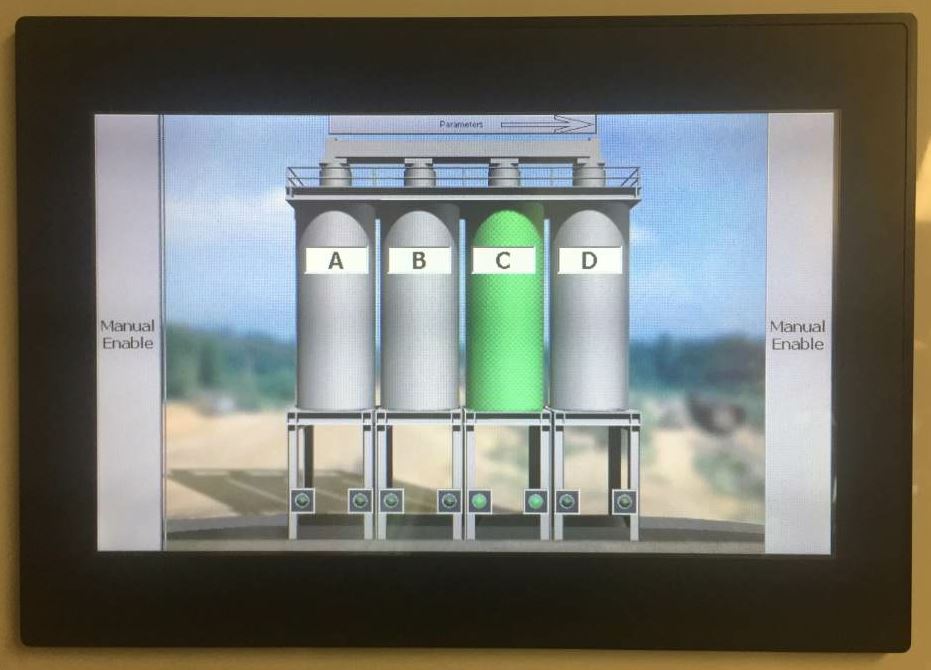

Libra Systems Inc.

The new silo safety system from Libra Systems

Libra Systems Inc., Harleysville, Pennsylvania, introduced its NextGen Silo Safety System November 2018 to guard against the dangerous and expensive accident of inadvertently opening the wrong silo at loadout.

“The Silo Safety System is designed to avoid equipment damage, personal injury, litigation, and lost production by dramatically reducing the possibility of opening the wrong silo.

“Both the legacy and new Silo Safety System provide these functions:

- Reduces the possibility of opening the wrong silo

- Independent of, and compatible with, existing automation and manual switches, it blocks attempts to open the wrong silo

- No operator interaction normally needed – it’s always on guard

“Additional features offered by the next generation system include:

- Fully graphic screen

- Automatically detects space between cab and trailer

- Auto-alerts for potentially defective sensors

- Pedestal or panel mount options”

For more information, contact Greg Fleisch at (215) 256-1700 X123 or gfleisch@librasystems.com.

Meeker Equipment Co.

The Meeker Hot Mix Silo System

Meeker Equipment Co. Inc., Belleville, Pennsylvania, offers the Meeker Hot Mix Silo Systems to convey hot-mix asphalt (HMA) and store it for loading into trucks.

“Hot Mix Silos allow producers to produce hot mix asphalt while trucks are not at the plant. This helps with scheduling of trucks and keeps the plant running and making homogenous mixes.”

For more information, contact Derek Garrett at (717) 667-6000 x140 or DerekGarrett@meekerequipment.com.

Haver & Boecker

Haver & Boecker, St. Catharines, Ontario, launched its new F-Class portable plant in November 2018 with as many as three screen decks for quarry and mining operations.

“The portable plant features a custom-built chasses equipped with six hydraulic run-on jacks to level the plant and minimize equipment wear.”

The F-Class portable plant’s “feed conveyor, cross conveyor and fine conveyor are hydraulically operated for precise material placement. The plant’s fines chute has full-width access door that allows users to easily unload material build-up, and an oversize chute features AR liners that are bolted on for easy replacement. The F-Class vibrating screen has an advanced double eccentric shaft design, supported by four high-performance, double-spherical roller bearings.”

For more information, contact (800) 325-5993 or info@havercanada.com.

Hotmix Parts & Service

Hotmix Parts & Service, Louisville, Kentucky, introduced the Tank Monitor Nov. 1, 2018, to safely and accurately measure the level of liquids, fillers, dust and hot-mix asphalt (HMA). This is done without human contact with harsh chemicals or excessively hot materials.

“Determining the amount left in your AC tank with an antiquated lever and pulley system is a thing of the past with Hotmix Parts’ new Tank Monitor. This innovative piece of equipment makes it so that you never second-guess how much material is currently in your AC tank farms ever again.

“Through the use of this new cutting edge technology, the Tank Monitor is able to detect the accurate amount of liquid AC in your tank even in the presence of situations of heavy build up and volatile gases associated with asphalt storage. The Tank Monitor can monitor liquids, fillers, dust and HMA.”

For more information, contact a customer service rep at (800) 826-0223.

Process Heating Company Inc.

The Lo-Density® CLHR inline fuel-oil preheaters from Process Heating Company

Process Heating Company Inc., Seattle, offers the Lo-Density® CLHR Inline Electric Fuel-Oil Preheaters, which were fully released in 2017. They are designed to automatically provide precise temperature and viscosity control of heavy oils for steady delivery from the pump to the plant’s burner.

“Viscosity is the primary concern for producers who burn heavy or used fuel oil in their plants, as these oils become virtually impossible to pump at low ambient temperatures. Correct viscosity also provides proper atomization at the burner nozzle and clean burning of the oil. There are two methods available to adjust viscosity in heavy fuel oil. One is to blend the oil with expensive #2 heating oil or diesel fuel—raising operational costs because of higher fuel costs. The better method is to preheat the fuel, allowing heavier oils to move smoothly to the burner. PHCo inline heaters are fully automatic, easy to control, and—due to their removable drywell tubes—easy to clean, which is especially important when using recycled fuel oil.”

For more information, contact Rick Jay at (866) 682-1582 or rick@processheating.com.

Reliable Asphalt Products Inc.

Caption for image saved as PG Reliable Minds 0928

Reliable Asphalt Products Inc., Shelbyville, Kentucky, offers the Minds Control System.

“The Minds Control System is a comprehensive control system using advanced, Windows-based, customizable automation to control batch plants, drum plants, silo load-out, full plant control and data management for the asphalt industry. Minds currently controls many of the largest and most sophisticated plants in the industry, some as retrofits to existing facilities and others demanded by the contractor/owner for new facilities.

Find specs on www.reliableasphalt.com/minds-controls/.

Ruckit Inc.

Ruckit Inc., Austin, Texas, introduces the Ruckit platform, which is a collaborative logistics platform for contractors, materials producers and trucking companies to optimize the movement of bulk construction materials.

Ruckit’s platform includes a free mobile app for iOS and Android devices that enables companies to dispatch, manage and track in real-time all trucks for a job.

Real-time route tracking allows dispatchers and construction managers to receive personalized trucking recommendations to improve loading/unloading times, optimize haul routes and make more informed dispatching decisions. Operations implementing the powerful logistics tool have realized up to one extra load per truck per day. “Two of the top five bulk materials producers are using the Ruckit platform and are in various stages of rolling it out nation-wide, and one has already reported a 5 percent improvement in truck utilization,” Ruckit co-founder and CEO Kyle Kinsel said.

For more information, visit www.goruckit.com.