Systems Equipment’s 1292 Material Temperature Capture

BY AsphaltPro Staff

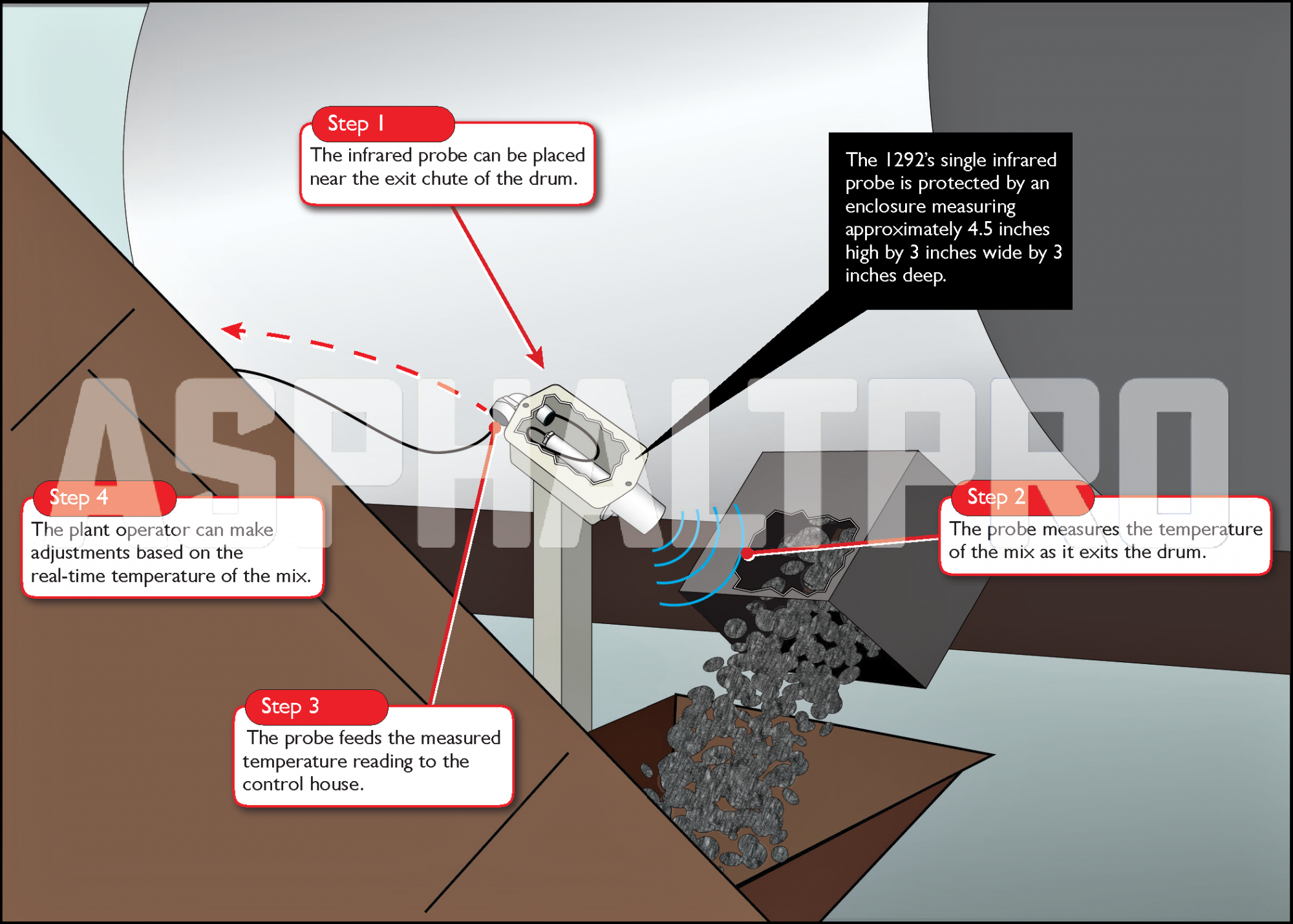

Asphalt producers and contractors need to measure and document the temperature of hot mix asphalt (HMA) for optimum quality control/quality assurance (QC/QA). To that end, the team at SYSTEMS Equipment, Waukon, Iowa, created the 1292 Material Temperature Capture at Time of Load element to work in conjunction with its Windows-based loadout system, the WIN-LC3000. Here’s how it works.

A single infrared probe protected by an enclosed housing assembly is mounted to each loadout silo—or to the drum, if used with the blend system. For the blend system, the active end of the probe is mounted to the chute at the end of the drum and directed toward the exiting mix. A small air valve incorporated into the enclosure prevents debris from attaching to the end of the probe and skewing the reading.

“With the 1292 assembly, the reading is almost instantaneous,” Fred Axmear, software engineer as Systems Equipment said. When the plant operator reads the real-time mix temperature, he can make adjustments as necessary for QC.

For the loadout system, the active end of the probe is mounted to the loadout silo frame and directed toward the truck bed. As loading proceeds, the probe measures the temperature of the newly loaded asphalt mix. The temperature reading is both stored in the loadout database and printed on the driver’s loadout ticket.

For more information, contact Systems Equipment at (563) 568-6387 or email info@systemsequipment.com.