Stansteel’s Safe-T-Station™

BY AsphaltPro Staff

When quality control techs collect samples of liquid asphalt cement (AC) at the asphalt plant, attention to safety is paramount. That’s why the team at Stansteel, Louisville, Kentucky, designed the Safe-T-Station™ to assist collection and minimize the risk of asphalt burns. Here’s how it works.

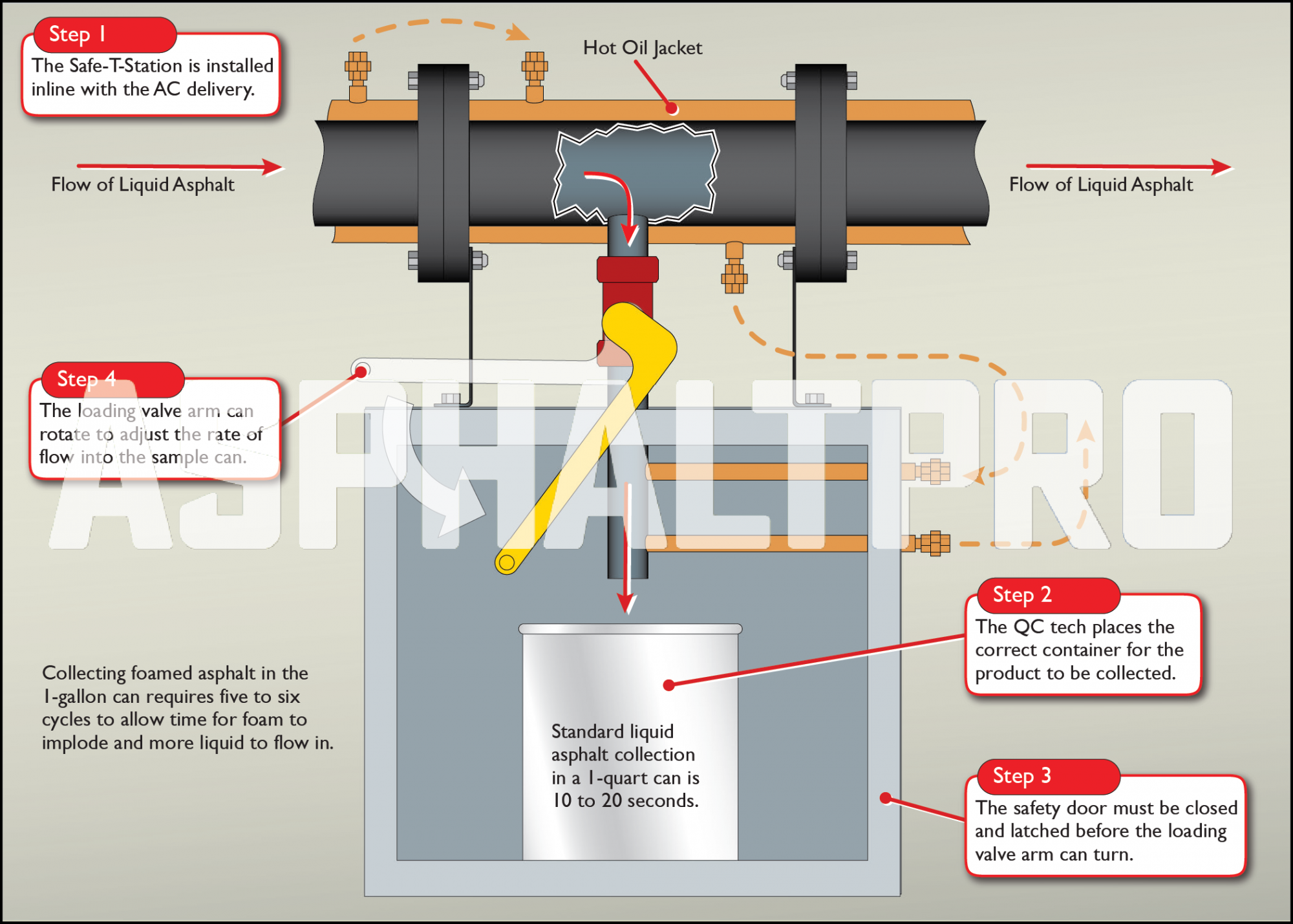

Stansteel’s Safe-T-Station is installed inline with the AC delivery to the plant’s mixing zone. As the liquid flows through the pipe, it will also flow into a collection container when the Safe-T-Station’s valve is open for collection.

The QC tech will wear a face shield, insulated gloves and chemical apron to help minimize the possibility of burns while handling loaded sample cans. He first unlatches the station’s cabinet door, which is constructed of safety glass, and opens the door to allow access to the chamber. He will place a sample can of either one-quart size for standard liquids or one-gallon size for foamed/expanding liquid asphalt, into place in the chamber. He will then close and latch the transparent safety door. Once the door is closed and latched, the loading valve arm will be clear to rotate downward into the loading position.

Next, the operator removes the loading valve arm safety pin. After pulling down on the lever arm, he can watch through the safety glass as liquid fills the sample can to the desired height. He will adjust the rate of flow from slow to fast by rotating the valve. To load a quart can with a standard liquid asphalt will take about 10 to 20 seconds.

When the sample can is filled and topped off to the desired amount, he will raise the lever arm and put the safety pin in the off position. With the lever arm in the secured off position, the access door can be unlatched and opened to retrieve the sample.

To collect a sample of foamed asphalt, he will use the one-gallon can, and five to six cycles of loading the can to the top—and then waiting for the foam to implode so more liquid asphalt can be added up to the top again. Each cycle should take about 30 seconds.

For more information, contact Rick Rees at (502) 905-4145 or rrees@stansteel.com.