Roadtec’s Autotracking Package

BY AsphaltPro Staff

Roadtec’s Autotracking Package

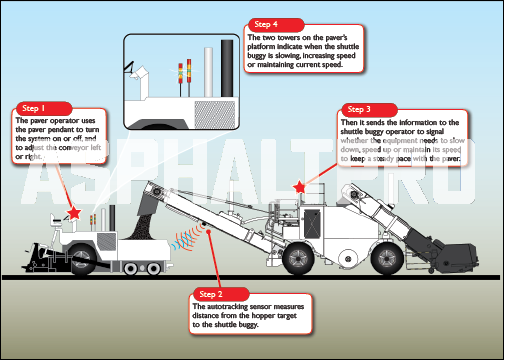

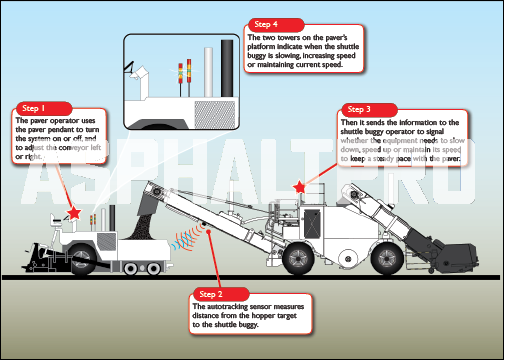

To decrease the number of machines each operator has to track, and to provide even operation of those machines, the engineering team at Roadtec, Chattanooga, developed the new Shuttle Buggy Autotracking Package. It uses wireless technology to get smooth material transfer while the paver sets a pace that the MTV matches. Here’s how it works:

First, the paver operator turns the system on or off by pressing a button on the paver pendant at his platform. This sends a wireless signal to the autotracking sensor, which is mounted or hung near the discharge chute of the material transfer vehicle (MTV) and the paver.

The autotracking sensor is mounted aboard the C3 conveyor and monitors the distance to the hopper target. (An optional, second sensor can monitor the pile height within the hopper.) The hopper should be fixed with a smooth, flat surface for the sensor to use as a reference point to send and receive distance signals. If you don’t have a flat surface, weld a small piece of metal to the hopper’s exterior. As the autotracking sensor monitors distance, it zings a wireless signal to the shuttle buggy operator to let him know that the equipment’s speed is—or is not—matching that of the paver.

If the MTV needs to slow down, the autotracking sensor provides that information to the operator. The amber and red lights at the top portion of the two cylindrical towers on the paver operator’s station will light up to indicate the shuttle buggy is slowing down. If the shuttle buggy needs to speed up, the amber and red lights at the bottom portion of the two cylindrical towers will light up to indicate the increase in speed. When the green lights in the center of the towers are illuminated, the operators can rest assured that the shuttle buggy is at an acceptable distance from the paver—moving at the same speed.

If the operator needs to adjust the discharge conveyor to hit the hopper target, he can press the appropriate button on the paver pendant to signal the conveyor to move to the right or left.

For more information, contact Roadtec at (423) 265-0600 or visit www.roadtec.com.