Reliable’s AquaFoam®

BY AsphaltPro Staff

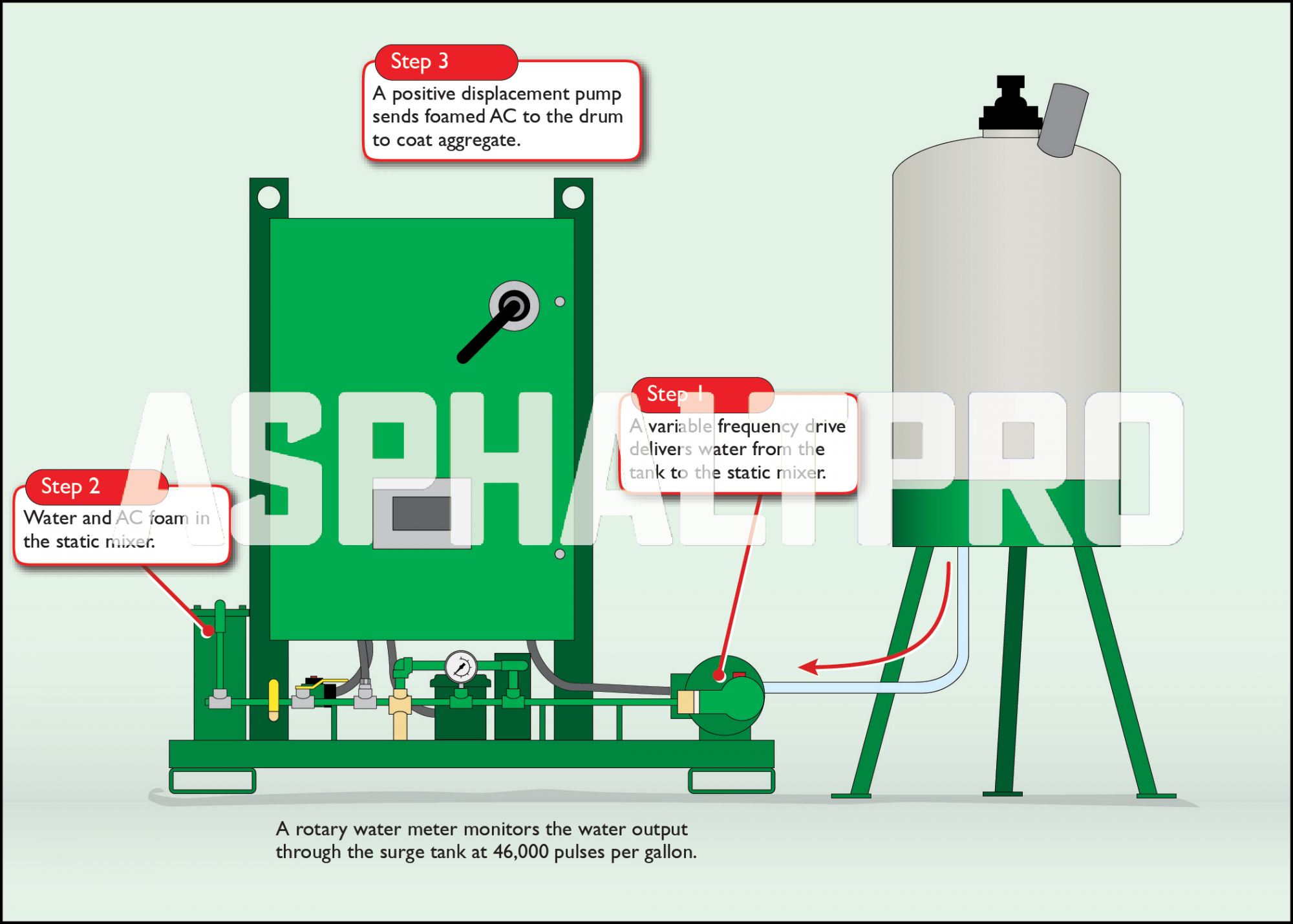

The AquaFoam® warm mix system from Reliable Asphalt Products, Shelbyville, Ky., is designed to foam liquid asphalt cement (AC) binder with water to create a foamed warm-mix asphalt (WMA) product. Here’s how it works.

First, a technician fits the AquaFoam components in line at the HMA plant. The 3-inch jacketed injector goes directly into the AC injection line.

When the crew is ready to make mix, the plant operator flips a switch to remotely control the AquaFoam from the control panel in the control house. The positive displacement, high-pressure injection pump then uses a variable frequency drive to deliver water from the water tank to a static mixer, where it meets the AC.

A rotary water meter monitors the water output through the 65-gallon poly water surge tank and Y strainer, at 46,000 pulses per gallon. An electronic level senses high and low water levels. An alarm will sound for the plant operator if there’s an interruption in water flow to protect the pump from an empty water tank situation.

From the static mixer, a positive displacement pump sends foamed binder to the drum for WMA production.

From the control house, the plant operator flips a switch to remotely control when the AquaFoam is operating and when a valve will trigger a bypass to allow the plant to resume production of hot mix. The system can be switched back and forth from auto to manual control.

For more information about the AquaFoam WMA technology, contact David Childers at (866) 647-1782 or visit www.ReliableAsphalt.com.