R18 Certifies Higher Calibration Costs

BY Sandy Lender

Typically, standards voted on within the International Organization for Standardization (ISO) don’t impact the asphalt industry directly, according to Ray Brown, Ph.D., director emeritus at the National Center for Asphalt Technology (NCAT) at Auburn University. This truism has changed to some extent with the adoption of ISO 17025 calibration of measurement standards by the American Association of State and Highway Transportation Officials in 2016, which AASHTO began enforcing in April of this year. Members of the asphalt industry helped us understand how the changes may affect a lab near you.

“There are a number of organizations that can provide accreditation for laboratories,” Brown shared. “These include AASHTO, ISO, Corps of Engineers and…many more. In the United States, by far, the most common organization for accreditation for asphalt pavement testing is AASHTO through the AASHTO Accreditation Program (AAP) for materials testing laboratories. All state DOTs, contractors and commercial labs use this organization for accreditation.”

In 2016, AASHTO R18 adopted the ISO 17025 calibration of measurement standards. This change required measurement standards to be calibrated by an ISO 17025-certified laboratory unless the calibration was completed by the manufacturer of the measurement standard. Enforcement of this requirement began April 13, 2017.

In 2017 AASHTO R18 removed the exception that allowed for manufacturers to calibrate their products without being ISO 17025-certified and replaced it with an exemption for proprietary measurement standards only. These requirements will be enforced starting Jan. 1, 2018.

The stringent parameters of the measurement standard are intended to create an error-free testing environment for labs. Todd M. Arnold, Ph.D., the general manager of Pine Test Equipment, Grove City, Pennsylvania, wrote: “The purpose of this requirement is to build confidence into test results because test results are used to make important and potentially costly decisions.”

Bob Lutz, the manager of the AASHTO Materials Reference Laboratory (AMRL), provided insight into the AAP, including the quality management system.

“The quality management system review includes reviewing the lab’s documented policies, procedures and records. Your quality management system must meet the requirements of AASHTO R-18, which is for sale for $55 at the online AASHTO bookstore.” Let’s use Pine Test Equipment and a fictional ABC Asphalt Company, as an example to explain what’s happening. When ABC Asphalt orders a new gyratory compactor, it is calibrated and certified for use at Pine’s factory prior to shipping. When it is delivered to ABC Asphalt’s accredited lab, the technician sets it up in the exact place where it will be operated, and calls the local certifying technician to calibrate it again. ABC Asphalt pays a fee for the local technician to use certified calibration tools to calibrate the gyratory compactor again. Depending on which gyratory compactor the company has purchased, those tools include a subset of the following:

- AFGCLR05C: 5,000-pound Proving Ring (AFGC125X, AFG1 and AFG2 force)

- AFG123: “1-2-3” Height Blocks (AFGC125X, AFG1 and AFG2 height)• AFGBA04: Height Tube (AFGB1 height)

- AFGBA06: Load Cell and Meter (AFGB1 pressure)• AFLS1 “RAM” with AFLSC01 Calibration Tube: (internal angle on all machines)

Dave Savage of Pine Test Equipment stated clearly, “If you want to have an accredited lab, your devices have to be calibrated.” He pointed out, now that AASHTO has incorporated ISO 17025, several calibration tools have to be certified by a testing service that meets the requirement. “It’s a much more stringent standard,” he stated. AsphaltPro posed some questions to Arnold to help lab managers wade through the upcoming change.

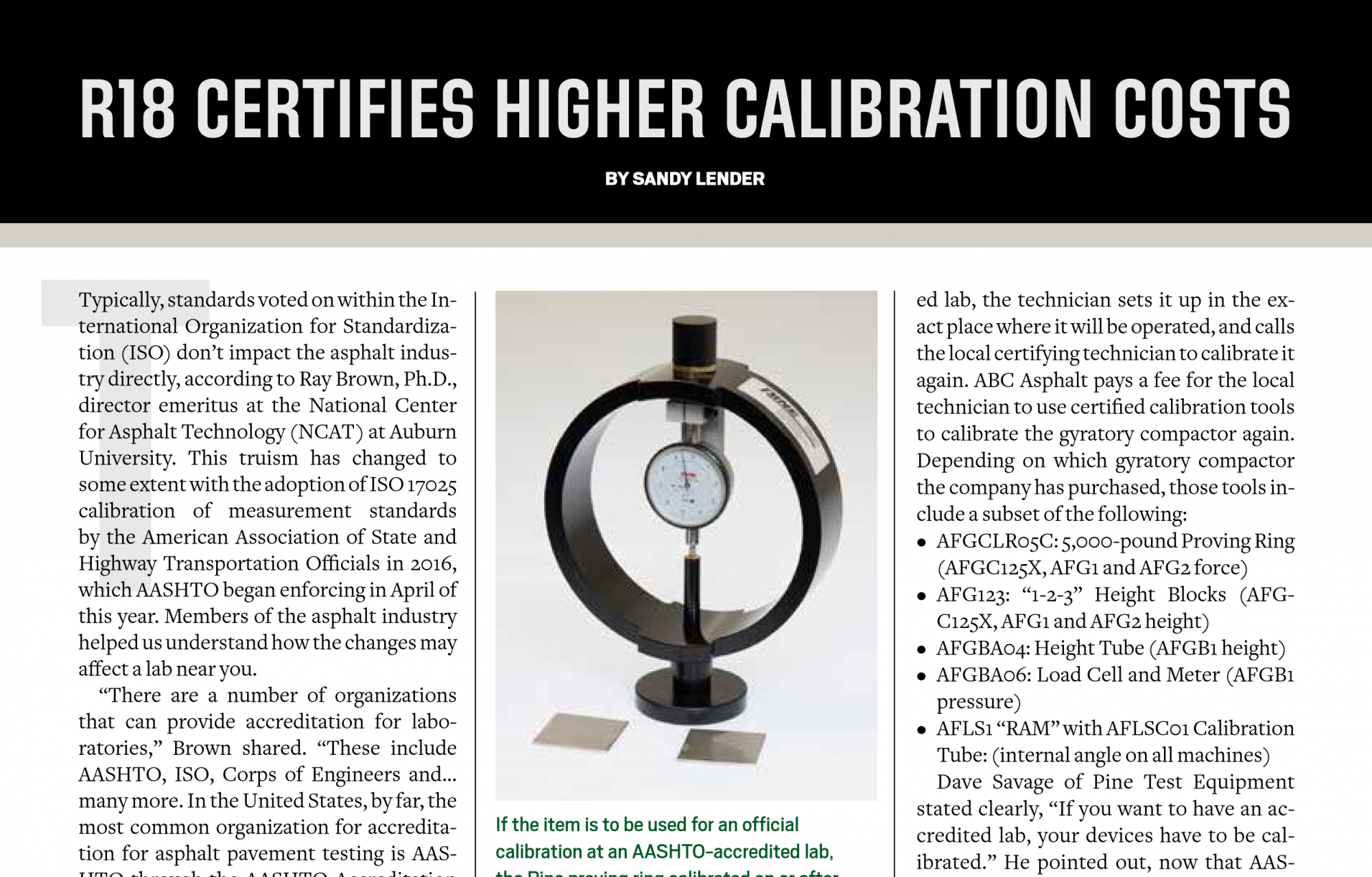

If the item is to be used for an official calibration at an AASHTO-accredited lab, the Pine proving ring calibrated on or after Jan. 1, 2018 must be calibrated by an ISO 17025-certified lab for calibrating force applicable force measurement devices. Pine field technicians will carry devices that comply with AASHTO R18.

AsphaltPro: Which equipment will be directly affected by the updated AASHTO R18 requirement?

Todd Arnold: The AASHTO R18 changes mean the AFGCLR05C Proving Ring, the AFG123 Height Blocks, the AFGBA04 Height Tube, and the AFGBA06 Load Cell and Meter, must be calibrated by an ISO/IEC 17025-certified laboratory if they are used to calibrate and issue a certificate of calibration for a gyratory compactor in a laboratory seeking AASHTO accreditation. An AFGBA06 calibrated on or after April 13, 2017, must comply with this requirement. The AFGCLR05C Proving Ring, the AFG123 Height Blocks, and the AFGBA04 Height Tube calibrated on or after January 1, 2018, must comply with this requirement.

AsphaltPro: Will Pine Test Equipment personnel be qualified to calibrate equipment for customers after January 2018?

Todd Arnold: The AASHTO R18 adoption of the ISO 17025 requirement requires that the measurement standards, except for the RAM, carried and used by Pine’s field service technicians must be calibrated by an ISO 17025-certified laboratory for our calibration work to meet AASHTO R18 requirements. We will comply with R18.

AsphaltPro: For a lab that wishes to retain its AASHTO accreditation, what is the best way for the lab manager to find a qualified calibration technician?

Todd Arnold: If one is looking for someone to calibrate a Pine gyro, I am going to tell you that Pine technicians are the best in the business. Our technicians service Pine equipment. Generally speaking, to meet the new requirements, a technician needs to have measurement standards that are calibrated by an ISO 17025-certified laboratory. A lab manager can determine this by looking at the calibration certificate for the measurement standards. An ISO 17025-certified calibration will indicate it clearly on the certificate. The lab manager can also review the scope document of the lab to ensure it is certified to conduct the calibration work done on the certificate.

The Pine load cell & meter system must be ISO 17025-calibrated if its calibration certificate is dated on or after April 13, 2017, if the system is used to conduct an official calibration and if AASHTO accreditation matters to the owner of the gyratory compactor. The Pine proving ring, height blocks and height tube must be ISO 17025-calibrated if their calibration certificate date is on or after Jan. 1, 2018, if the items are used to conduct an official calibration, and if AASHTO accreditation matters to the owner of the gyratory compactor.

Not all labs seek accreditation, but those that have implemented and maintained stringent quality control measures have done so to reap a number of financial and industry enhancing benefits. If a lab should elect to calibrate equipment with non-ISO 17025-certified measurement tools going forward, the lab flirts with the loss of accreditation and the benefits thereof. Arnold reminded readers that the process of maintaining accreditation begins with an accreditation auditor writing a report on noncompliance.

Lutz provided a breakdown of the on-site assessment for labs that have received accreditation through AASHTO’s AMRL. It shows that the assessment takes place approximately every 24 months. The assessor from AMRL labels any findings in his report as “nonconformities,” and the lab has 90 days from the issuance of the report to not only address the nonconformity, but to communicate its solution to AMRL. For something as simple as conforming to the updated R18, the lab must subcontract technicians who are ISO 17025-certified or who carry with them calibration tools that have been calibrated by such labs. While this may incur additional cost to bring a qualified field tech to your lab prior to spring 2018 startup, it’s a cost of doing quality business.