Meeker’s Freedom Air Baghouse

BY AsphaltPro Staff

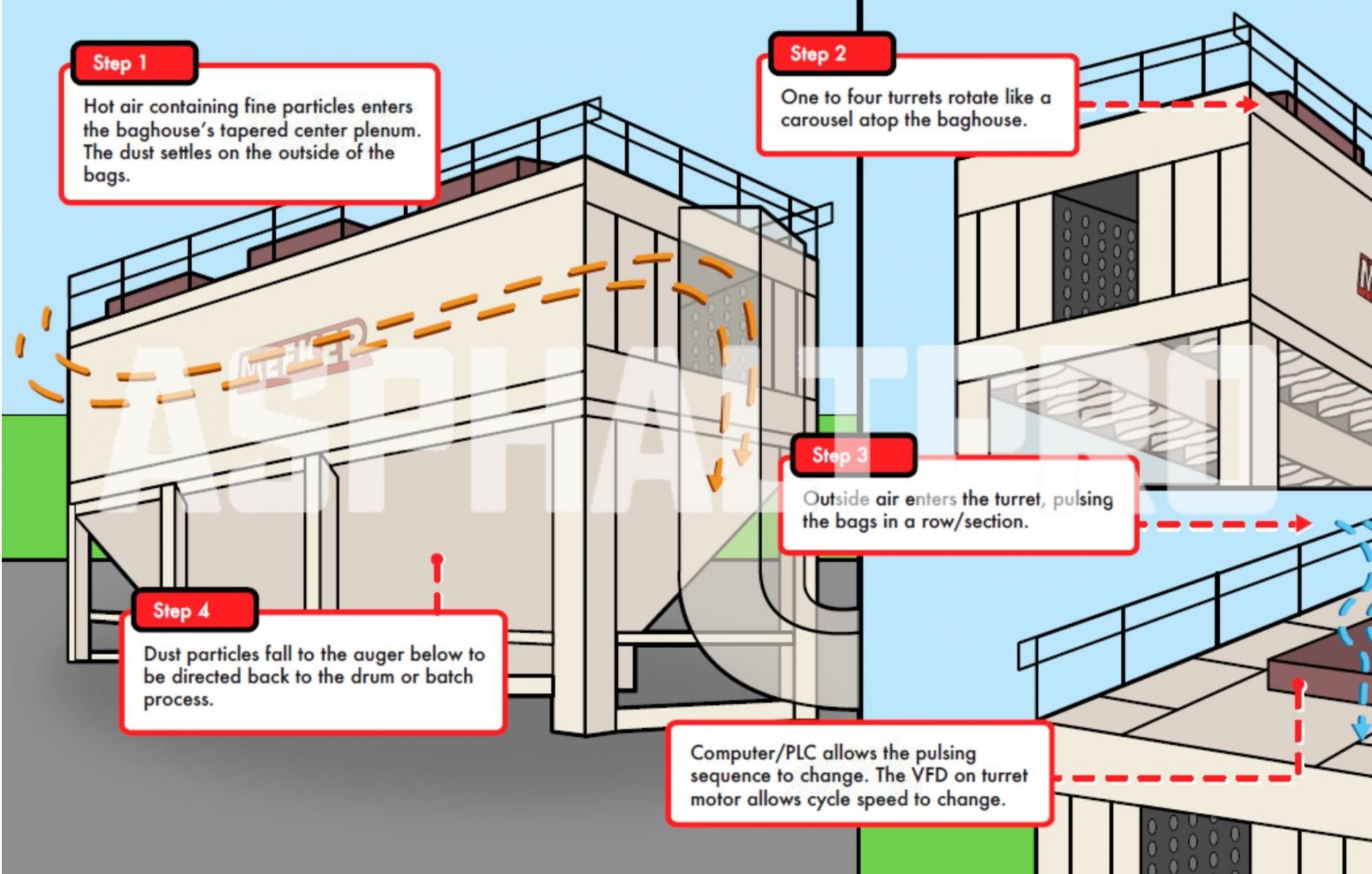

Meeker Equipment Co. Inc., Belleville, Pennsylvania, has launched a new reverse air baghouse called the Freedom Air that provides unique control of the turrets, does not require an air compressor and uses stainless steel turrets. Here’s how it works.

Hot air containing fine particles enters the baghouse’s center plenum, which is tapered to evenly distribute air across all bags as it moves from one end of the house to the other. Plasma-cut holes across the sidewalls of the center plenum assist with this distribution of air on the bags, allowing dust to collect on the outside of the bags.

On top of the baghouse, multiple stainless steel turrets turn like a carousel to facilitate cleaning the bags. Variable frequency drives (VFDs) move the turrets quickly or slowly, depending upon dust loading on the bags. The turrets pulse the bags in the configuration selected by the operator. For example, the turrets can pulse in a line—1 then 2 then 3—or a different pattern—3 then 1 then 2.

Pressure drop begins across the bags as hot air moves across them. When the turret moves to the row to be cleaned, the pressure rises as fresh outside air flows from the turret to a row of bags; the reverse air blows down the bags from the inside out. (High pressure air flows to low pressure.) The system can be set to pulse only half of the bags on a turret. This allows for even flow of dust from the baghouse back to the drum or batch processes.

If a turret goes off line, the baghouse can still operate. The operator simply takes the selected turret off-line and the plant continues.

For more information, contact Meeker at (888) 333-0323.