MDOT, NCAT Show How to Place New Rejuvenating Fog Seal

BY Sandy Lender

Officials at the Mississippi Department of Transportation (MDOT) have taken another step forward in their study of pavement preservation and maintenance methods in concert with the National Center for Asphalt Technology (NCAT) at Auburn University, Alabama. The Mississippi team led by State Materials Engineer Jeff Curtis included Asphalt Laboratory Engineer Cass Coon and Soils Laboratory Engineer William Sullivan. The core team from NCAT was led by Postdoctoral Researcher Raquel Moraes, Ph.D., and included the new test track manager, Jason Nelson, and an assistant research engineer, Grant Julian.

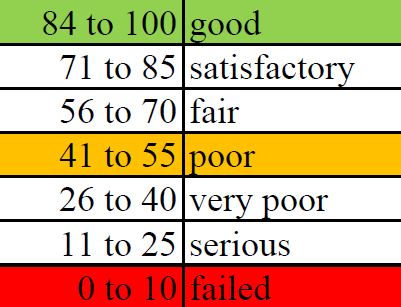

The treatment course for this pavement with a PCI between 70 and 80 is a rejuvenating fog seal, applied at a rate of 0.10 gallon per square yard.

The recent effort began with a set of test strips on the North Paddock near the NCAT Test Track and continues on Test Section S3 of the 2018 research cycle of the track.

Let’s use their work with one of the products—Delta Mist asphalt pavement rejuvenator seal product—to investigate how to perform a lasting, rejuvenating fog seal treatment.

Biochemistry

The January 2016 issue of AsphaltPro gave an in-depth discussion of the biochemistry behind the Delta S rejuvenator from Collaborative Aggregates LLC, headquartered in Wilmington, Massachusetts. The next product developed by the research scientists at the Warner Babcock Institute for Green Chemistry and Collaborative Aggregates is Delta Mist, which is a spray-applied, topical application that performs as a penetrating asphalt rejuvenator on asphalt pavements. It is designed to assist in repairing the damage from sunlight and air to the asphalt binder in a pavement. When the liquid is sprayed onto the pavement, the modifier penetrates the asphalt binder molecules where it repairs damage from oxidation. As the seal cures, it re-establishes the bonding of the “renewed” asphalt binder to the aggregate, in-place.

From left, Grant Julian, assistant research engineer, and Jason Nelson, test track manager at NCAT

This helps return the bond between the asphalt binder and aggregate to a stable state. Delta Mist is 100 percent plant based and contains no asphalt.

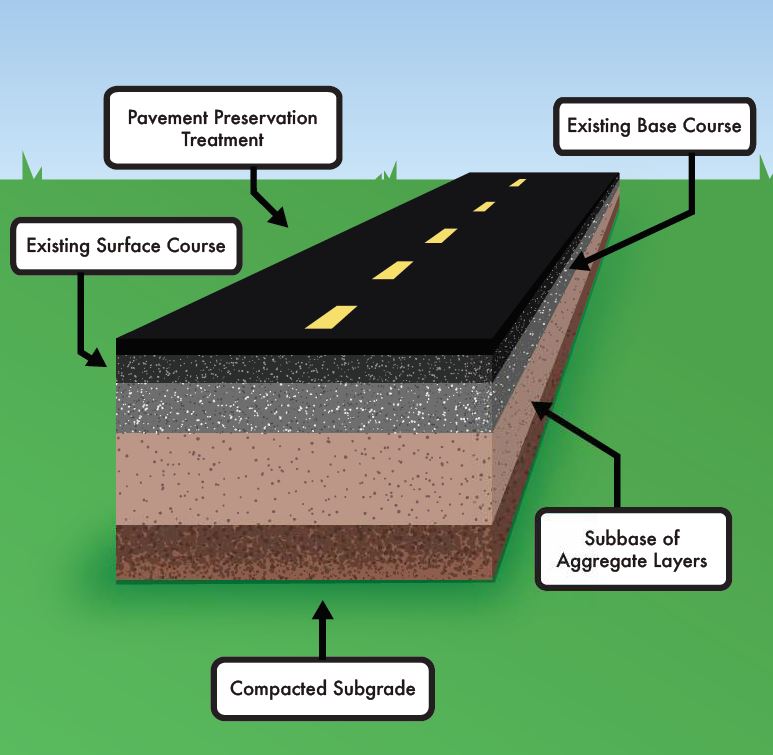

NCAT’s Moraes provided a statement that the combination of fog seals and asphalt rejuvenators—rejuvenating seals—is a low-cost option for retarding the surface deterioration of pavements. She wrote: “A fog seal consists of a slow setting asphalt emulsion diluted with one to four equal parts of water and applied at rates between 0.06-0.13 gal/yd2 over an existing pavement surface without the use of cover aggregate. It is intended to penetrate into the surface pores of an existing asphalt pavement with the purpose of sealing very small cracks and surface voids in addition to coating aggregate particles.”

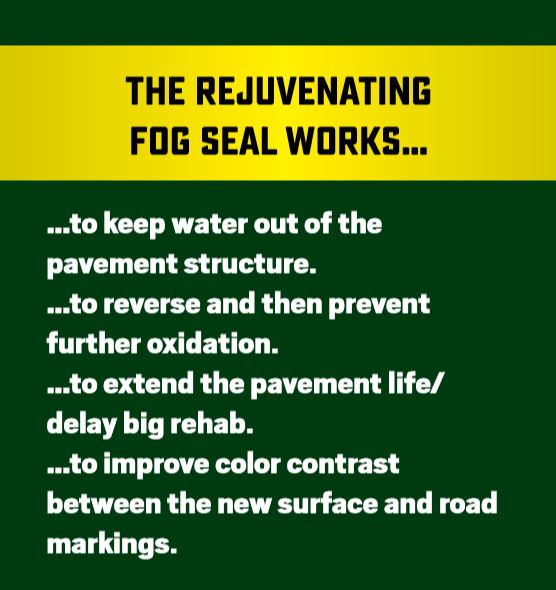

Of rejuvenators, she wrote that the petroleum or bio-based products, “restore the chemical composition of aged asphalt binder by rebalancing the ratio of asphaltenes to maltenes. Thus, the purpose of the rejuvenators is to penetrate into the pavement, soften the asphalt binder, improving its flexibility, and reducing the likelihood of cohesive failure. Furthermore, rejuvenators can also minimize future aging caused by oxidation. Therefore, rejuvenating seals are surface treatments suitable to treat raveled and aged pavements.”

Collaborative Aggregates has pointed out in the past that its green chemistry products are designed to correct the bonds between molecules within asphalt binder film.

According to the Pavement Preservation and Recycling Association (PPRA), a fog seal “is a single application, typically light, of emulsified asphalt to an existing asphalt surface.” The fog seal is typically used on pavements with a Pavement Condition Index (PCI) rating of 70 or better, which means the surface is slightly oxidized from weathering.

Standard Pavement Condition Index™ Rating Scale

Source information courtesy International Slurry Surfacing Association

If the PCI indicates a pavement that’s a bit more oxidized, between 70 and 85, an agency may opt for a rejuvenating emulsion. The PPRA site explains: “Rejuvenating emulsions can be applied as a fog seal when the level of surface distresses is greater than what would normally be used as a criterion for typical chip or fog seals.”

Perform Rejuvenating Seal Treatment

Before the rejuvenating fog seal project begins, a test strip will help you get your settings right. It’s best, of course, to place a test strip on a similar-scoring pavement section and under similar conditions to those you expect during your project. Using best practices, the researchers at NCAT tested eight rejuvenators for the Tennessee and Mississippi DOTs during August and September 2018.

The researchers explained the purpose of the test strips: “The objective of the study was to screen among eight different surface rejuvenators that could, potentially, be selected as the surface treatment for sections sponsored at the 2018 NCAT Test Track cycle.” They met their objective, with MDOT opting to test two rejuvenators from the offerings.

- Step 1 is to prepare the surface, sweeping or blowing away dust and debris. (If you’re performing the treatment on a parking lot, you’ll want to clean stalls that have engine oil spots, etc.)

- Step 2 is to double-check the ambient conditions. When the NCAT team prepared for the MDOT test section, they waited for a window of good weather in November 2018. You’ll want a dry surface and ambient temperatures of 50 degrees F or higher. PPRA recommends a pavement temperature above 59 degrees F. You’ll want a dry surface, but consider, though, how a light spray of water under extremely hot, dry pavement conditions can help an emulsion break in a timely fashion. If the pavement is too hot and too dry, that dryness could “encourage” the emulsion to break too quickly and leave your treatment to fail. Depending on the pavement condition, temperature and humidity level, you’ll spray water in a “fog” without letting the water collect on the pavement.

- Step 3 is to calibrate and set your distributor for your application rate.

- Step 4 is to spray according to the agency’s specification. At the test track in

November, that meant 0.10 gallon per square yard. You want a nice fan pattern from the nozzles of the spray bar on the distributor truck and a consistent, clean look from the material on the pavement.

The team from NCAT summarized the steps based on the weather pattern they experienced prior to work. When it came time to apply the rejuvenating seal to Section S03, the Auburn area experienced rainy days. They had to wait for clear skies and dry pavement.

Raquel Moraes, postdoctoral researcher at NCAT

“Location, weather, traffic loading, and pavement conditions are factors used to determine if a rejuvenating fog seal application is appropriate to treat a pavement. In order to construct a durable surface treatment layer, the key factors in determining success of the application are condition of the existing pavement, application rate, residual binder content, proper distribution operation, and emulsion break and set times. Furthermore, the following pavement surface characteristics must be considered: cleanliness, age, texture and pavement type. The pavement surface receiving the surface treatment should be free of any substance that might inhibit bond. In this study, the cleaning operation of the surface prior to application of Delta Mist was accomplished through manual and mechanical brooming.”

What to Expect

The Etnyre Centennial Black Topper sprayed the Delta Mist rejuvenator at a rate of 0.10 gallon per square yard onto section S03 of the NCAT Test Track in November 2018.

The fog seal is designed to improve the surface appearance and to seal minor cracks. It fills surface voids. It inhibits raveling. Its purpose is not to add structure, but to add two to four years of life to the pavement, giving agencies or counties more time before resorting to bigger/costlier repairs. By opting for the rejuvenating fog seal treatment, the agency could expect to restore the “oxidized components in the asphalt binder and to further slow down the rate of aging and oxidization,” according to the team making strides at NCAT.

Once again, that means another two to four years of pavement life for the agency. As the 2018 track test sections undergo increased ESALs, the NCAT researchers will continue to update Mississippi and other interested parties in the progress of the selected rejuvenating seals.