How to Train Paver Console Basics

BY John Ball

Even though it’s tempting to think younger workers joining the paving crew grew up with video game virtual reality headsets and computer keyboards, that doesn’t translate to instant equipment operation.

The joystick on the paver operator’s platform moves a heavy piece of machinery. And that’s only one component of a confusing array of switches, knobs and dials for the new operator to master.

Let’s begin this month’s training article with the joystick. Some foremen or supervisors will yell up to the paver operator about “throttle.” The joystick control is what they’re yelling for you to adjust. To move the paver, you’ll push this lever forward as far as you can push it, and then turn the rheostat knob (to the right of the joystick) to the comfortable speed per minute.

This is called “dialing in your speed,” and you’re setting it in feet per minute (fpm). You adjust the speed according to the timing of the material coming in. You’ll turn the knob until you find where 25 to 30 fpm is on the speedometer. Then lock it in.

Check out the article “Paving Speed Changes Quality” on TheAsphaltPro.com to learn more about that.

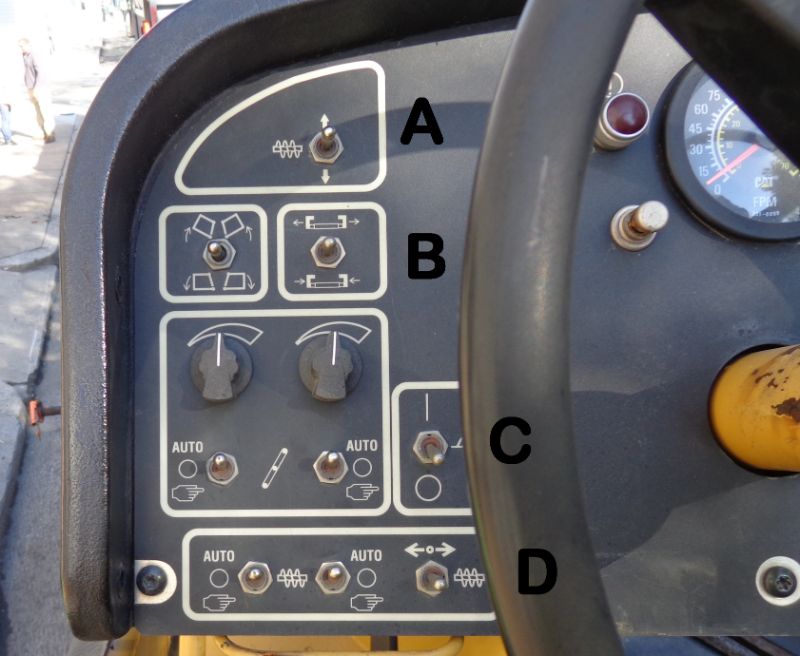

Moving forward is only a part of the paver operator’s job. All the other symbols and switches on the console have meanings and make changes to the machine that then make changes to the mat quality. Let’s take a closer look at them now.

The area next to the bold letter A is where the paver operator will set the height of the augers. This will be at least 2 inches above what we’re going to lay. The toggle switch moves north and south to move the augers either up or down. The augers will normally go from zero to 6 inches in movement, but remember that they’re not actually touching the ground when they’re at zero. Get out your tape measure and double-check your start height.

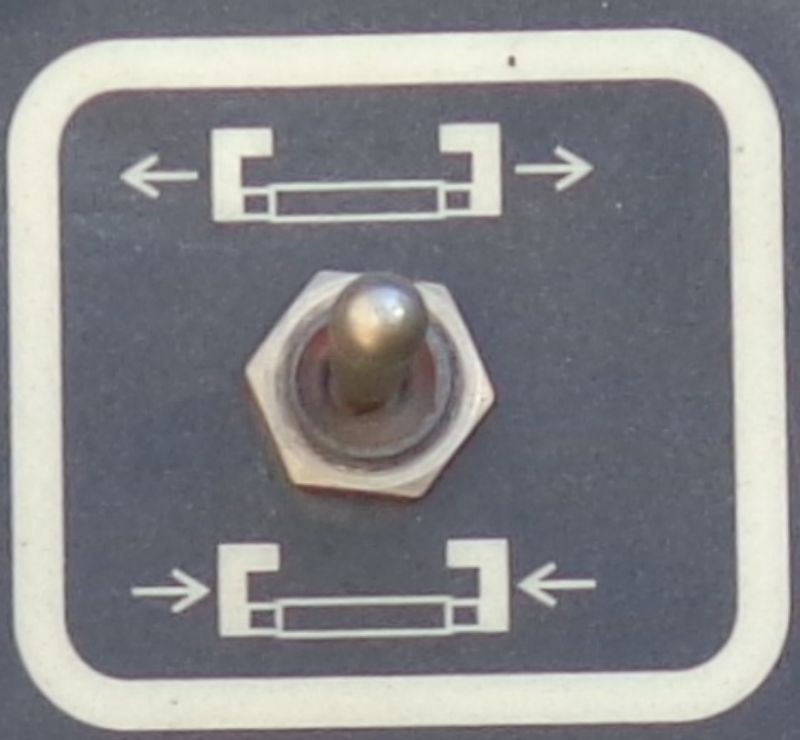

The two areas next to the bold letter B are where the paver operator will fold the hopper wings up or down, and where he will grab or release truck wheel locks. For the hopper wings, don’t flutter them. This puts too much stress on the hinges and welds.

Not all tractors come equipped with a truck lock-and-release. This mechanism is designed to hold trucks close against the push rollers on the front of the paver so mix is delivered perfectly into the hopper. The paver operator, who is in the best position to observe the mix flowing into the hopper, can then determine when it’s safe to signal the driver to lower the truck bed; he can release the truck locking mechanism and signal for the driver to pull away. This reduces accidental spills that cost the crew time, money and quality.

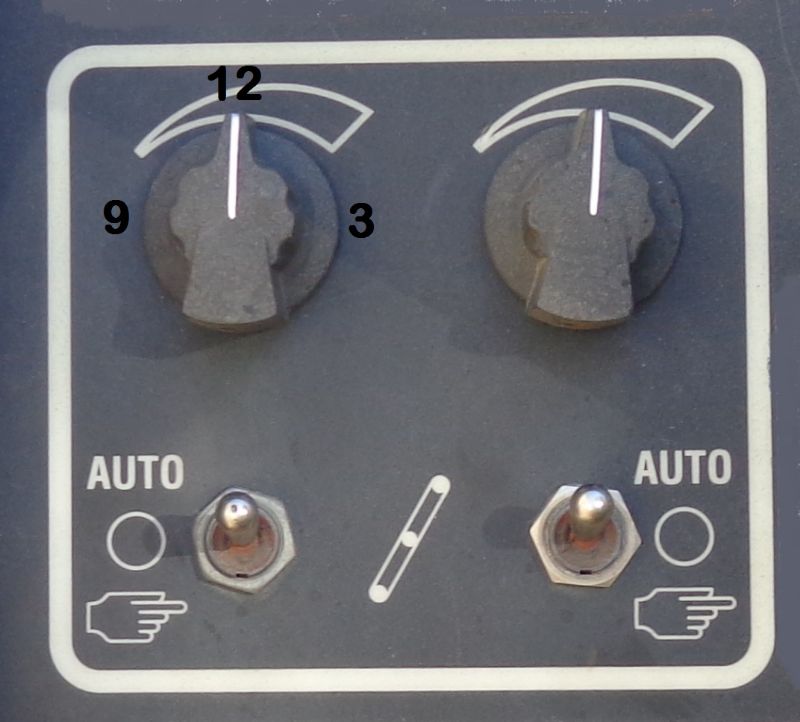

The areas next to the bold letter C are where the paver operator will control the speed of the conveyors (more on them in the next section) and where he can turn on/off the screed vibrators/eccentrics, or leave them in automatic. The control for the speed of the eccentrics is located under the step, where the screed operator controls it. At 6 o’clock it’s off; at 12 o’clock it’s set in automatic.

The area next to the bold letter D is where the paver operator will adjust the speed of the augers. Notice there is a toggle on the left that will operate the left auger; a toggle on the right that will operate the right auger; and a toggle on the far right with a double-arrow above it that dictates whether the augers are in single or double-operating mode. In other words, the toggle on the far right can be set to allow the operator to move the augers independently of one another, or to move both augers simultaneously.

By switching the two toggles south to the hand symbol, the operator puts the augers in manual mode. By switching the toggles north to the “Auto” word, the operator puts them in automatic mode. While the toggle at the top of this console panel adjusts the height of the augers, this set of toggles at the bottom of the console panel lets the operator adjust their speed, thus manipulating the head of material and movement of material to the endgates. Remember, a good head of material is mix half-way up the augers consistently across the length of the auger chamber.

Taking a closer look at the area labeled C on the left-hand side of the paver console, let’s talk about the conveyor controls for a minute. The knob on the left controls the left conveyor in the floor of the hopper and the knob on the right controls the right conveyor in the floor of the hopper. When you look at these knobs, look at them as if you’re looking at the face of a clock. Think of the top—or north—as 12 o’clock. The far right will be 3 o’clock. The far left will be 9 o’clock.

The swoosh, or arrow, drawn above each knob represents the speed of the conveyor chains. When you turn the knob toward 3 o’clock, you’re opening up the conveyor or speeding up the flow of material. This matters because sometimes the roadway isn’t perfect and your screed operators need more or less material on one side or the other to fill in and get the mat perfect. If the head of material starts to get low or if the endgates start to flood, the screed operator will call up to the paver operator to modify the rate—or flow—of material.

We need to pave with a balanced screed, of course. It’s best to have the extensions the same on each side. A 10-foot paver paving a 12-foot lane should have 1-foot extensions on each side.

For example, the screed operator on the left-hand side of the paver can shout up to the paver operator to give more or less material to the left side of the machine. But if he doesn’t speak in specific terms, the paver operator won’t know how far to “dial” the knobs. If the screed operator speaks in terms of time, saying, “I need you to set the left side at 1 o’clock,” or “would you bump it to 2 o’clock?” then the operator will be able to set the correct conveyor more precisely.

To ask for a precise increase or decrease in tons flowing to the head of material, the screed operator would need to know paving width and depth, as well as how long it takes for the conveyor to go from front to back, which depends on paving speed. He’d have to make quick calculations to request exact tonnage changes. With the “time” system, he can request changes that both he and the paver operator can understand without assigning numerical values.

By switching the toggles at the bottom of this panel to Auto, the paver operator can put the conveyors in automatic mode. Or he can switch the toggles to manual mode, allowing him to change speed as needed.

John Ball is the proprietor of Top Quality Paving & Training, Manchester, New Hampshire. He provides personal, on-site paving consulting services around the United States and into Canada. For more information, contact him at (603) 493-1458 or tqpaving@yahoo.com.