Dynapac’s MF2500CS Material Feeder

BY AsphaltPro Staff

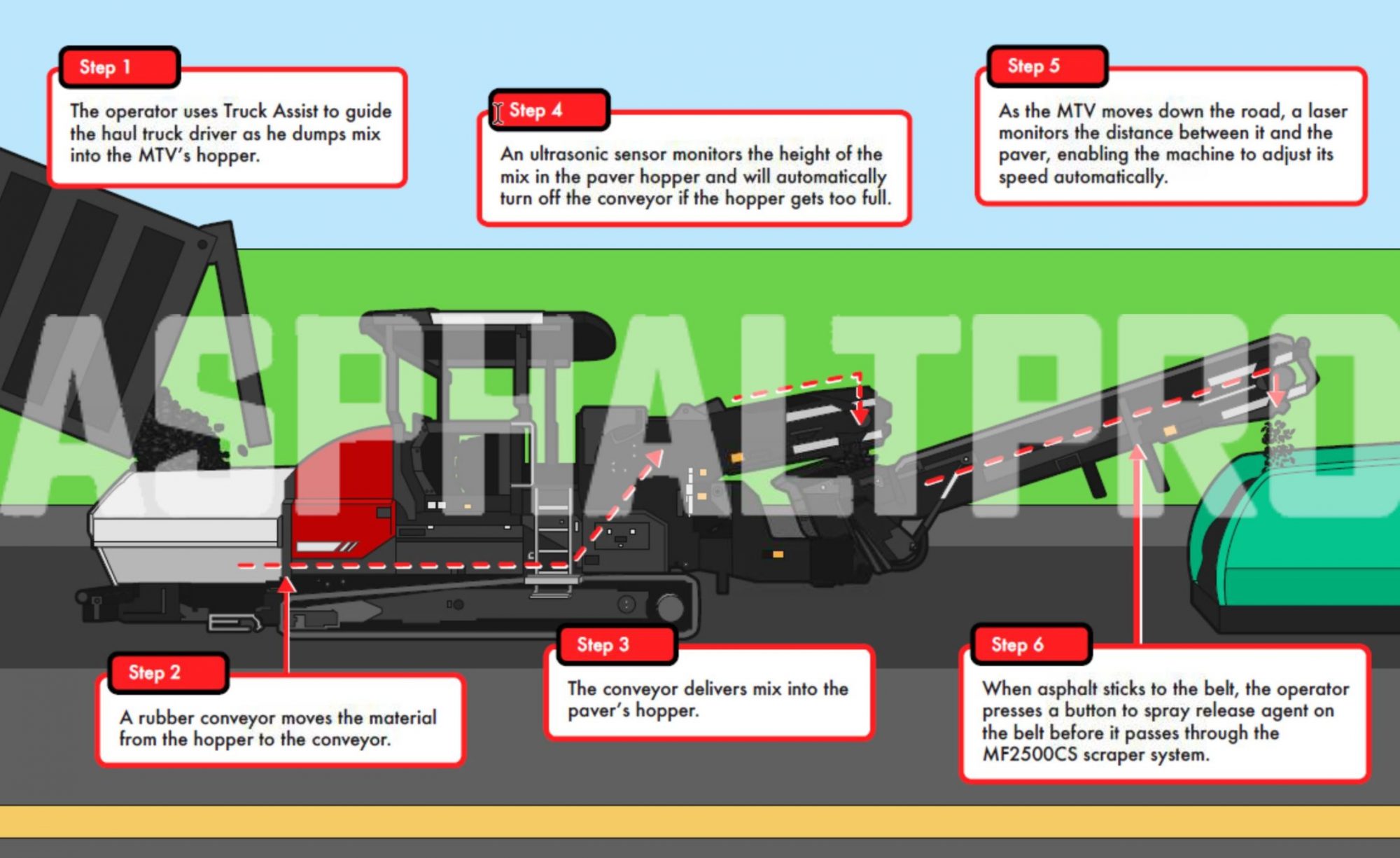

Material transfer vehicles (MTVs) can enable crews to pave continuously and eliminate the possibility of haul trucks bumping the paver. At World of Asphalt 2019, the team at Dynapac, Fort Mill, South Carolina, launched its MF2500CS material feeder to the North America market. With its high capacity of 4,000 tons per hour, the MF2500CS is designed for heavy highway paving contractors. Here’s how it works.

At the start of the shift, the operator will configure the operator’s station.

When a haul truck arrives, the operator pushes a button to activate Dynapac’s Truck Assist system, which uses a series of colored lights to direct the truck driver. A laser on top of the feeder monitors the distance between the feeder and the truck. When the truck reaches the distance the operator chooses (1.5, 1 or 0.5 feet), the lights will instruct him to stop. The lights also indicate when to start and stop dumping and when to pull away. If the haul truck driver overflows the feeder’s hopper, track cleaners will direct that material between the MTV’s tracks so it can stay level and continue its straight path down the road.

A 4-foot-wide rubber belt moves the material from the hopper toward the conveyor at the back of the machine, transferring up to a 35-ton truckload in as little as 35 seconds. The MF2500CS is also available with an add-on swing conveyor for offset feeding applications up to 55 degrees in either direction.

If the paver is directly behind the MF2500CS, the operator can use automatic distance control and automatic feed functions. The operator sets a preferred distance between the feeder and the paver, and a laser located underneath the feeder will monitor that distance. The feeder then adjusts speed to maintain that distance. As the conveyor feeds material into the paver’s hopper, an ultrasonic sensor monitors the height of the mix and will automatically turn off the conveyor if the hopper gets too full.

As the paving train moves along, the feeder operator will keep an eye on the belt to ensure it remains clean. If asphalt does stick to the belt, the operator can press a button to spray the belt with release agent; material then passes through the MF2500CS scraper system.

For more information, contact Vijayakumar Palanisamy at vijayakumar.palanisamy@dynapac.com or (303) 248-9040.