Check Out What You Need for 2019 Work Zones

BY AsphaltPro Staff

This issue hits the streets before we get back to paving the streets. It’s still technically “winter weather” in much of North America, thus pothole patching may be going strong in your neck of the woods. While that’s going on, many contractors are doing what you’re doing: thinking about the upcoming paving and pavement maintenance season.

Is your fleet ready? The original equipment manufacturers (OEMs) listed below have components, parts and pieces, as well as full hunks of iron, software add-ons and consulting services to help you make the fleet street-ready.

For example, the team at Neal Manufacturing, a division of Blastcrete Equipment LLC, Anniston, Alabama, specializes in pavement maintenance equipment and released a preservation package that includes the DA 350 in 2018. Maury Bagwell, the lead engineer at Neal Manufacturing writes that the sealcoating machine allows operators to use one machine to tackle four tasks associated with sealcoating jobs.

1.Blowing and cleaning.

2.Cutting in.

3.Spraying.

4.Squeegee application.

Bagwell explained, “Together, spraying and squeegeeing can deliver a sealcoat that lasts as much as 40 percent longer than either method alone. From pre-application preparation to extended protection after the job is done, the DA 350 offers contractors a way to do it all with a single machine.” You can get more information from (770) 830-1282 or eric@nealequip.com.

Then the team at Topcon has released the Topcon SmoothRide resurfacing system, which is designed to assist road resurfacing contractors in determining thickness boundaries while maintaining projected yield without the need for road or lane closures.

Murray Lodge, senior vice president and general manager of the Topcon Positioning Group Construction Business Unit, shared: “We’ve developed a way to scan roads at highway speeds with no need for lane closures, crash trucks, escorts or any other typical road survey collection obstacles. With the new RD-M1 scanning unit, the system maps the existing surface elevations…providing more accurate data needed to confidently estimate materials, as well as form the basis of the final design surface.”

The SmoothRide system uses a Topcon RD-M1 (Realistic Dimension-Mapping One) road resurfacing scanner that is attached to a vehicle. The downward facing laser scanner connects to a standard tow hitch or the front of any vehicle with standard tow hooks. The unit is designed to collect millions of points at scan rates of up to 100 times per second.

The collected data is automatically timestamped and stored for the next step of data management and point cloud generation. The mounted scanner captures millions of data points that are collected safely from the cab of the truck or car. Topcon points out that the driver can begin a road-surface surveying session by clicking the start button on their laptop computer and go.

The RD-M1 employs Collect 2.0 graphical collection software, which features an interface status bar that indicates the optimum speed for collecting road information based on the project requirements.

“I like that we can collect accurate topos while driving 50 miles per hour,” stated Chris Smithson, project manager with Big Creek Construction, Lorena, Texas. “We used it recently on a 3.5-mile section of Ranch Road 2838 in Mexai, Texas, where we were able to give the state more accurate cross sections and dirt quantities on the two-lane road and shoulders project we worked on. It saved us time and money.”

A feature called “Memos” is designed to allow operators to create balloons with messages on a map. The collected data can also be made visible in the processing software—enabling specific site conditions to be noted for future reference.

A “Manage Runs” feature is designed to enable operation without necessitating an internet connection. Operators can copy data collections to a USB drive, delete them from the hard drive, and add or remove them from the manager.

The RD-M1 Collect 2.0 software has a “Plan Route” feature that allows for the import of kml files of predetermined routes.

Kriss Maas, manager of machine control, Topcon, said: “Using the map downloader, operators can be assured of having all map details visible while collecting data, without the need of an internet connection. Additionally, overlapping locations can be managed by creating areas where predefined overlaps are required for the project. The detailed road surface scanning can be used to create and manage large point cloud information with our intuitive ‘Mobile Master Office’ software. The data can then be seamlessly transferred into MAGNET Office software’s ‘Resurfacing’ module to bring out the full array of software features needed to meet smoothness and cross slope requirements, while adhering to any minimum or maximum thickness specified for the job.”

“We use the 3D scanner part of SmoothRide as a survey tool to safely collect the data we need and eliminate hours of cross-section measurements,” stated John Dowalter, survey and machine control manager for Shelly and Sands, Zanesville, Ohio. “The system’s RD-M1 Scanner is great for capturing bridge approaches that sometimes have a big skew leading up to the bridge surface. That feature helped tremendously on a recent resurfacing section of I-71 between Columbus and Cleveland, which has a number of bridges that could have occupied hours of time for my crew.”

New and updated equipment and software only matters to your bottom line if you can get it in a timely fashion. AsphaltPro has shared the parts ordering portals and advances available in the marketplace before, and now companies such as Dynapac have announcements about their increasing efficiencies.

The cloud-based, after-sales service solutions provider Syncron™, based out of Stockholm, announced Jan. 30 that Dynapac, based in Atlanta, has achieved and maintains a 97 percent fill rate by using Syncron Inventory™. It has been reported that humans require at least $3.7 trillion of investment in global economic infrastructure every year from now until 2035, thus updates to roads and airports will be a lucrative and important business. Companies like Dynapac are focused on ensuring failing parts are repaired proactively and that complex, global service parts inventory is optimized.

“At Dynapac, ensuring part availability to keep our machines up and running is our top priority,” said Abhijit Som, vice president aftermarket at Dynapac. “The road industry is very demanding when it comes to uptime. Oftentimes, roads are built overnight, and crews only have a set number of hours to complete the job. This makes proactively repairing machines to support maximized product uptime paramount to success. With Syncron, we can manage 150,000 unique items and have visibility into the entire global network…”

With machine lifetimes of up to 20 years, there are multiple slow-moving, critical parts that Dynapac must ensure are available when and where customers need them. Because demand trends for these items are not standard, a sophisticated service parts inventory planning solution is necessary. Going forward, Dynapac aims to further connect its sensor-equipped machines with its data management and service parts inventory planning systems via the Syncron Service Cloud. More paving machines are being equipped with IoT sensors and Dynapac plans to leverage the data collected from these machines to provide in-depth reporting and analytics for its customers—all to maximize product uptime.

BOMAG Americas Inc.

BOMAG Americas Inc., Ridgeway, South Carolina, offers the BOMAG BM 2200/75 cold mill for pavement preservation. It is designed for milling of half-lane widths of 86.6 inches. It is designed for selective milling of road and base materials in large-scale projects such as mainline, highway, major urban roadway and airport rehabilitation projects.

“The BM 2200/75 mill’s 771-hp engine delivers the power needed for high-performance milling at depths reaching 13.8 inches. Multiple quick-change milling drum options are available, all built with high-quality hardened materials and optimized cutting tooth arrangement for high-efficiency asphalt removal. The base section of the cutting tool holder is identical for all drums.

“BOMAG’s BMS 15 milling tooth holder system delivers superior milling productivity with low wear to extend service life. The base tooth holder features a maintenance-free bolt-on design, while the tapered tooth retainer claw features a low-resistance profile for more cutting power.”

Get specs here.

For more information, contact Matt White at (903) 570-0988 or matt.white@bomag.com.

Enerpac

Enerpac, Menomonee Falls, Wisconsin, introduces the XC-Series cordless torque wrench pump for maintenance applications. This portable pump is designed to work in remote locations, sites that do not have access to power or where having electric cords could cause trip hazards

“The XC-Series cordless torque wrench pump features an interactive pendant that can be operated in manual or auto-cycle mode. The pendant allows the operator to store a set operating pressure. The pump has an easily accessible user-adjustable relief valve for precise pressure control along with a bladder reservoir that allows the pump to be used in any position.

“Additional features include LED indicators that provide visual and vibratory feedback of the pump operation and an integrated handle and carrying strap for portability. The pump also includes a 28-volt battery with lithium-ion technology for maximum battery performance and a quick, one-hour charger.”

For more information, visit www.enerpac.com.

FORTA® Corporation

FORTA® Corporation, Grove City, Pennsylvania, introduces its Surface-EXT™ fiber for micro surfacing and slurry seal applications.

Surface-EXT is an alkali and acid-resistant glass fiber specifically designed to extend the life of slurry seal and micro surfacing applications without change to the mix design. It has a specific gravity similar to that of the aggregate, allowing it to disperse into the micro/slurry mix. Once in the mix, the flexural strength and durability are enhanced, according to the manufacturer.

The Surface-EXT is incorporated directly into the mix with FORTA’s patented fiber dispenser, the Ranger. The Ranger mobile fiber dispenser attaches to continuous and truck-mounted equipment and work along with current controls. Check out the Preservation Pro supplement mailing with our May edition for a full write-up on the fiber.

For more information, contact Rebecca Hawke at (724) 458-5221.

Hamm

Hamm’s patented, split oscillation drum can be used for compacting challenging surfaces and curved sections.

Hamm, Antioch, Tennessee, introduced the oscillation technology for split drum compactors (models Hamm DV+ 70i VO-S, DV+ 90i VO-S) at the World of Asphalt 2019 in Indianapolis.

“Oscillation technology is used for breakdown, intermediate and finish positions to achieve fast dynamic compaction. The Hamm DV+ Series combines benefits of split drum compaction with oscillation.”

“Oscillation rollers can begin dynamic compaction directly behind the paver and then perform intermediate compaction. Even with cooler mat temperatures toward the end of compaction, nonaggressive oscillation attains density without overcompacting the lift and crushing aggregate. When using oscillation compaction, the time available for compaction is significantly greater than with vibratory rollers.”

Find specs here.

For more information, contact Matt Graves at (615) 501-0600 or matt.graves@wirtgen-group.com.

John Deere

John Deere, Moline, Illinois, unveiled three new L-Series utility wheel loaders with improved cabs for the paving marketplace.

Behind the wheel, EH loader controls with integrated third and fourth function auxiliary hydraulics provide faster cycle times. Two multifunction buttons integrated into the hydraulic controls allow the operator to assign a function to each button. This loader also has an ergonomically designed, seat-mounted right-hand joystick with a standard forward-neutral-reverse switch and fully integrated auxiliary hydraulic controls. A throttle lock option removes the need for the operator to push the throttle pedal to maintain engine speed.

“Improvements to the machine boom structure directly result in increased productivity. The design increases visibility to the coupler, bucket or forks, reducing overall cycle times, material spillage and equipment damage. Additional bucket options include enhanced production buckets with integrated spill guards, profiled side cutters and greater rollback.”

For more information, visit www.JohnDeere.com.

Neal Manufacturing

Neal Manufacturing, a division of Blastcrete Equipment LLC, Anniston, Alabama, offers the Asphalt Preservation Equipment Package, featuring the DA 350 sealcoating machine and high-volume road maintenance vehicle. The two elements of the preservation package are designed to provide efficiency and high-quality results on any size job. The DA 350 allows quick prep work and sealcoating around curbs and gutters. The high-volume road maintenance vehicle then delivers high material output for larger projects.

“The DA 350 features a built-in, high-powered blower and automatic cutting-in attachment. It includes a squeegee and spray bar for effectively applying sealcoat material for a smooth finish. The high-volume road maintenance vehicle features Neal Manufacturing’s Generation IV pump that delivers infinitely variable outputs from 0-150 gpm.”

See specs here.

For more information, contact Scott Knighton at (256) 235-2700 or scott@blastcrete.com.

Roadtec Inc.

Roadtec’s RP-250 features a large footprint that provides increased traction and flotation.

Roadtec Inc., Chattanooga, offers the RP-250 heavy-duty, 10-foot paver that combines the advantages of rubber tires with the tractive effort of a crawler paver. The large footprint of the 250-horsepower machine offers increased traction and flotation.

“The RP-250’s large tires and frame-raise provide idea weight distribution and tractive effort. With the RP-250’s unique augmented steering, steering is assisted by the rear wheels and operators have precise control, especially in turning. The paver’s unique frame-raise ability allows the operator to control and adjust the frame position as needed.”

Get specs here.

For more information, find your local sales rep on Roadtec’s contact page.

TransTech Systems Inc.

The original non-nuclear asphalt density gauge, the PQI 380, is designed to provide fast, accurate density readings of the asphalt mat.

TransTech Systems Inc., Latham, New York, offers the non-nuclear asphalt density gauge, pavement quality indicator, PQI Model 380, which is designed to provide fast, accurate density readings of the asphalt mat.

“The TransTech Systems non-nuclear density gauge saves time, money and regulatory headaches.”

See specs here.

For more information, contact TransTech at (800) 724-6306 or sales@transtechsys.com.

Vögele

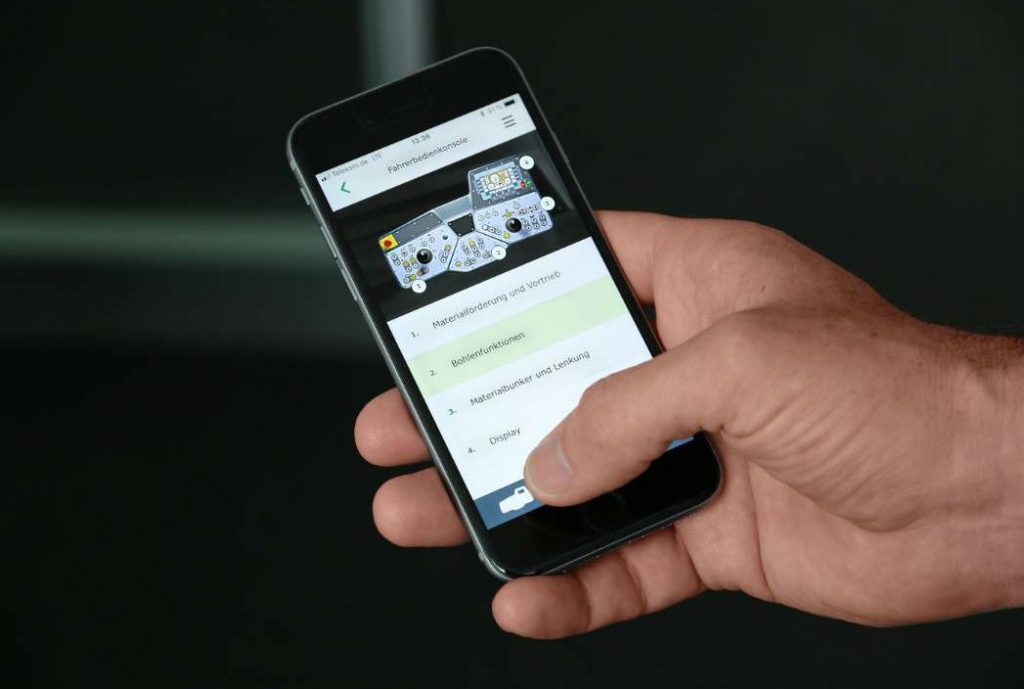

Vögele has developed an app and a web special, especially for the ErgoPlus 3 paver operating concept.

Vögele, Antioch, Tennessee, introduced the Vögele ErgoPlus 3 operating system app to the North American market during World of Asphalt 2019 in Indianapolis.

“This app with associated web support profiles the exclusive ErgoPlus 3 operating system from Vögele. All the functions of the paver and screed operators’ consoles are conveyed in a visual and practical way by means of short animations. Meanwhile, step-by-step videos give users an easy-to-grasp demonstration of entire work steps, as well as comprehensive automatic functions.”

“Users can access the app at any time on their PC, tablet or smartphone—on the job site, in the office or from home—and can make direct use of the information in their work.

The app complements the operator training courses available at our training centers, and users can now watch instructive videos, which helps eliminate errors while improving paving results and operations.”

View the web special here.

For more information, contact Matt Graves at (615) 501-0600 or matt.graves@wirtgen-group.com.

Wirtgen America Inc.

The PCD tools from Wirtgen are designed to provide a long service life and consistent milling pattern.

Wirtgen America Inc., Antioch, Tennessee, launched its PCD (Polycrystalline Diamond) cutting tools (“teeth”) during World of Asphalt 2019 in Indianapolis.

“The PCD milling tools are suitable for cold milling thanks to their improved geometry and materials. A long service life can be achieved thanks to the wear-resistant tool tip made of polycrystalline diamond. The very slight lengthwise wear ensures optimum evenness over the milled surface and consistently high machine feed.”

“PCD is a highly sophisticated, synthetically manufactured, strong mass of carbon and carbide. PCD tip is a crystalline diamond-coated carbide tip. The PCD tip consists of three layers: A concentrate of diamond particles in the upper layer, the interlayers and a tungsten carbide substrate. The interlayers enhance the durability and reliability of the PCD contact surface.”

For more information, contact Matt Graves at (615) 501-0600 or matt.graves@wirtgen-group.com.