BOMAG’s CR 1030 T Paver

BY AsphaltPro Staff

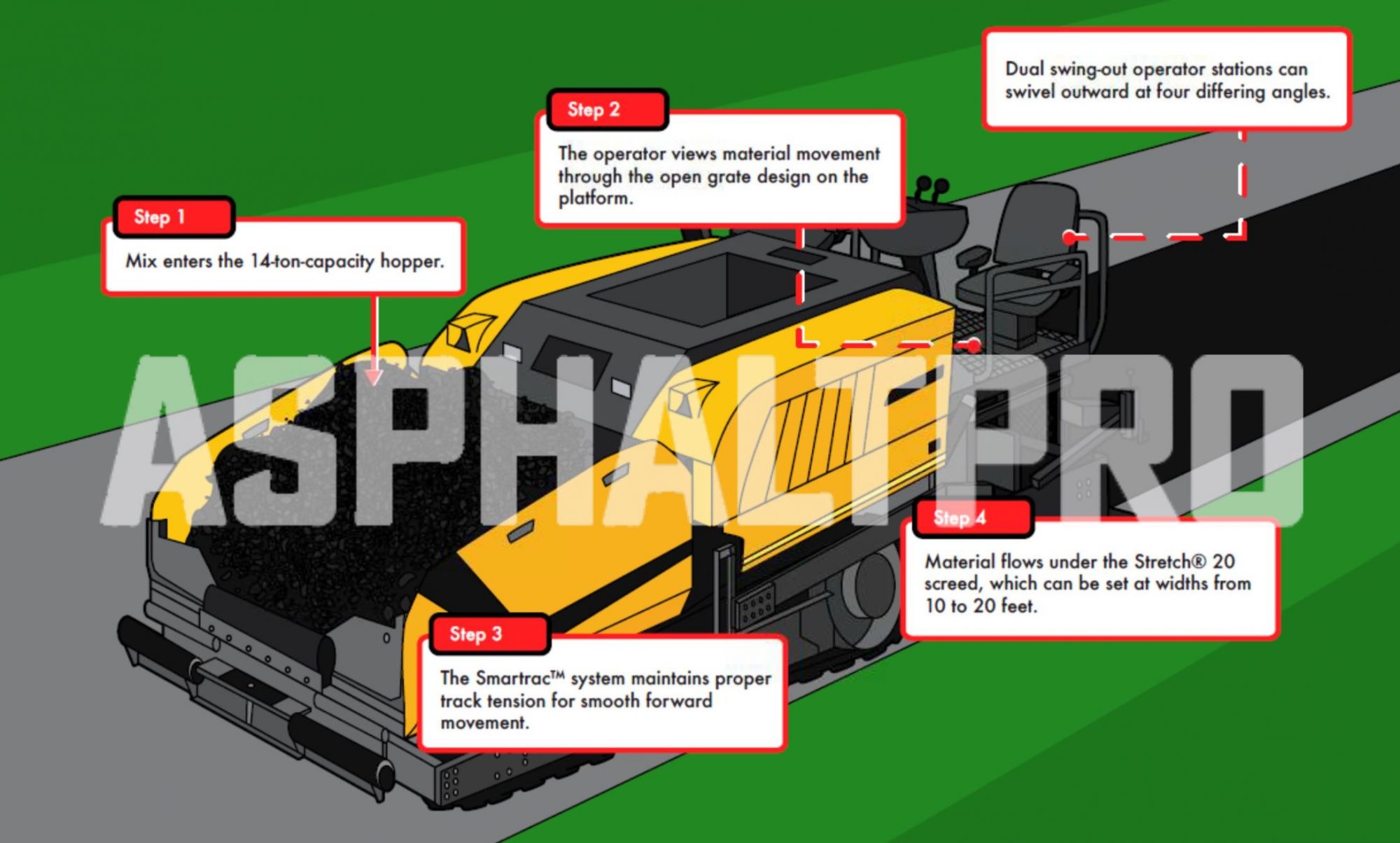

To pave smoothly without centerline segregation takes a skilled crew using proper equipment. The engineers at BOMAG Americas, Ridgeway, South Carolina, have launched the 10-foot highway class pavers with new features to assist operators; and the CR 1030 T paver has some upgrades. Here’s how it works.

First, the haul truck delivers mix to the 14-ton capacity hopper. The operator watches the movement of material more easily than in the past due to the sloped design of the sound-insulated composite engine hood. He looks through the open-grate design on the platform floor to monitor the head of material at the spreading augers.

Under the hood, the 225-horsepower Tier 4 Final engine powers full width paving as well as the screed’s generator and lights for nighttime paving, while consuming an average of less than 4 gallons of fuel per hour. As the paver moves forward, the Smartrac™ system on the CR 1030 T paver automatically maintains proper track tension, according to the manufacturer.

To help him keep his lines straight, the operator can swivel either of the dual swing-out operator stations outward at four different angles to view the sides of the paver and the endgates. The mix flows under the Stretch® 20 hydraulically extendible screed, which allows a hydraulically variable paving width from 10 to 20 feet. With extensions, the crew can pave up to 30 feet wide.

The CR 1030 series paver also comes in a wheeled version, the 1030 W, which has a standard hopper capacity of 16.7 tons and a 260-horsepower Tier 4 Final engine.

For more information, contact your local BOMAG dealer via www.bomag.com.