Astec’s Ranger J20 Mobile Crusher

BY AsphaltPro Staff

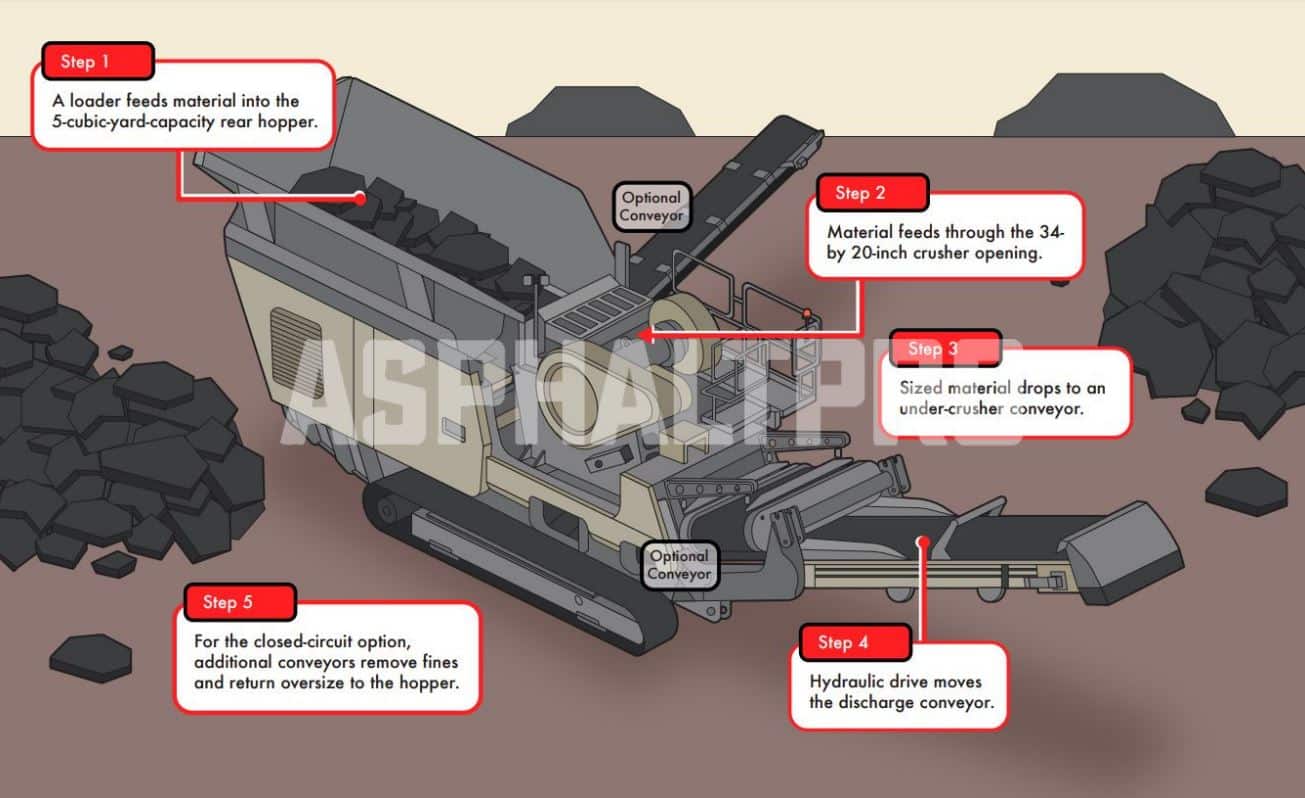

The Ranger™ J20 mobile jaw crusher from Astec Industries, Chattanooga, is designed for the smaller to mid-range contractors working in tight spaces for applications such as recycling concrete or asphalt; processing sand and gravel, aggregate; or screening topsoil and other materials. Here’s how it works:

The crew brings the mobile jaw crushing plant to the site and unfolds and sets up the machine from a centrally located control panel at ground-level. The crew can choose closed-circuit operation or choose open-circuit operation to feed material into another screening or crushing plant.

When the crew is ready for work, a loader (or other equipment) feeds material into the rear hopper, which has a capacity of 5 cubic yards and opening of 6 foot, 6 inches by 13 feet, 5 inches.

Quick Tip: Remember when feeding concrete that you want slabs to be no more than 18 inches.

Material falls through the crusher’s opening, which is 34 inches by 20 inches.

The crusher, powered by a CAT C4.4, 172-horsepower (129kw) or a Volvo Penta D5, 172-horsepower (129kw) engine, reduces material size as it drops to an under-crusher conveyor of 36-inch width. The conveyor uses hydraulic drive to carry material to a discharge height of up to 9 feet, 10 inches.

Listen to a product expert share important details at this link: https://youtu.be/BJAWiGSq2-8

For more information, visit www.AstecIndustries.com