Astec’s Green Pac

BY AsphaltPro Staff

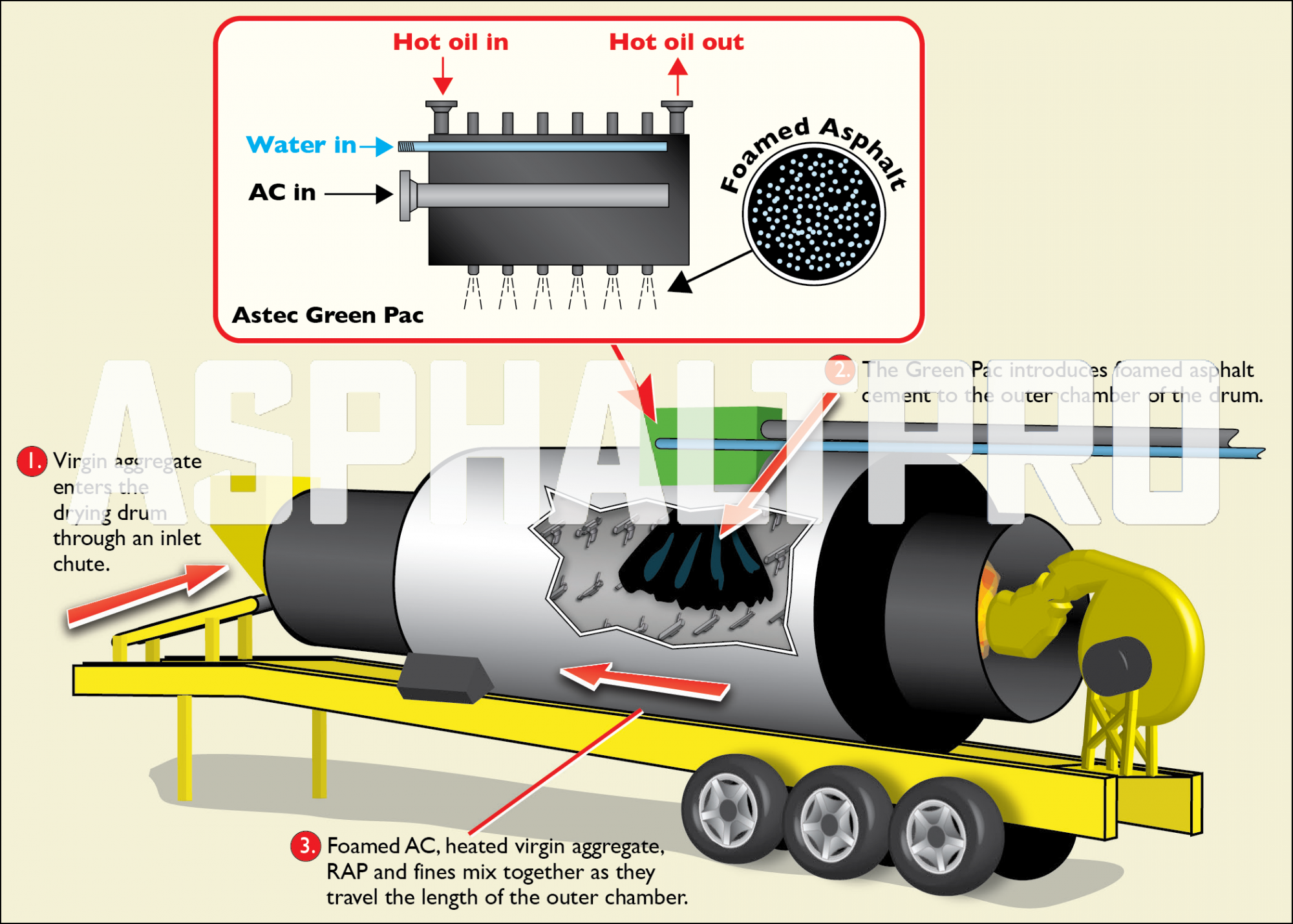

The Green Pac from Astec Inc., Chattanooga, is designed to allow the mixing of small amounts of water and asphalt cement (AC) to create microscopic bubbles during the mixing stage. The bubbles act to reduce the viscosity of the AC. Here’s how it works.

Aggregate is introduced to the drying drum, such as the Double Barrel™ or any other OEM’s equipment. It is introduced at the elevated end and moves toward the burner flame. At the same time, a common AC manifold delivers liquid asphalt to the Asphalt Green Pac affixed on the side of the drum. A positive displacement piston pump delivers water at a high pressure, but the pump speed can be modulated proportionally to the speed of the liquid AC pump.

The device consists of multiple AC solenoid valves and water solenoid valves, mixing chambers, and nozzles that are designed to pass AC and produce foam for up to 50 TPH of production each. Computer controls open and close the valves so that each assembly and nozzle operates in a narrow range of flow and back pressure to get proper foaming action. An additional valve in the Green Pac allows the operator to collect AC samples for testing.

The virgin aggregate travels the length of the inner drum, drying as it moves toward the burner flame before dropping through a series of holes to the outer drum chamber. In the outer chamber, it mixes with incoming RAP and fines, and all become coated with the incoming foamed AC. The heated virgin aggregate, RAP, fines and foamed AC are mixed together as they travel the length of the outer mixing chamber to an outlet chute on the side of the drum. This chute drops the mix into the base of the plant’s drag conveyor.

For more information about the Green Pac, contact Astec at (423) 867-4210.