Willow Designs’ Notch Wedge Pneumatic Roller

BY AsphaltPro Staff

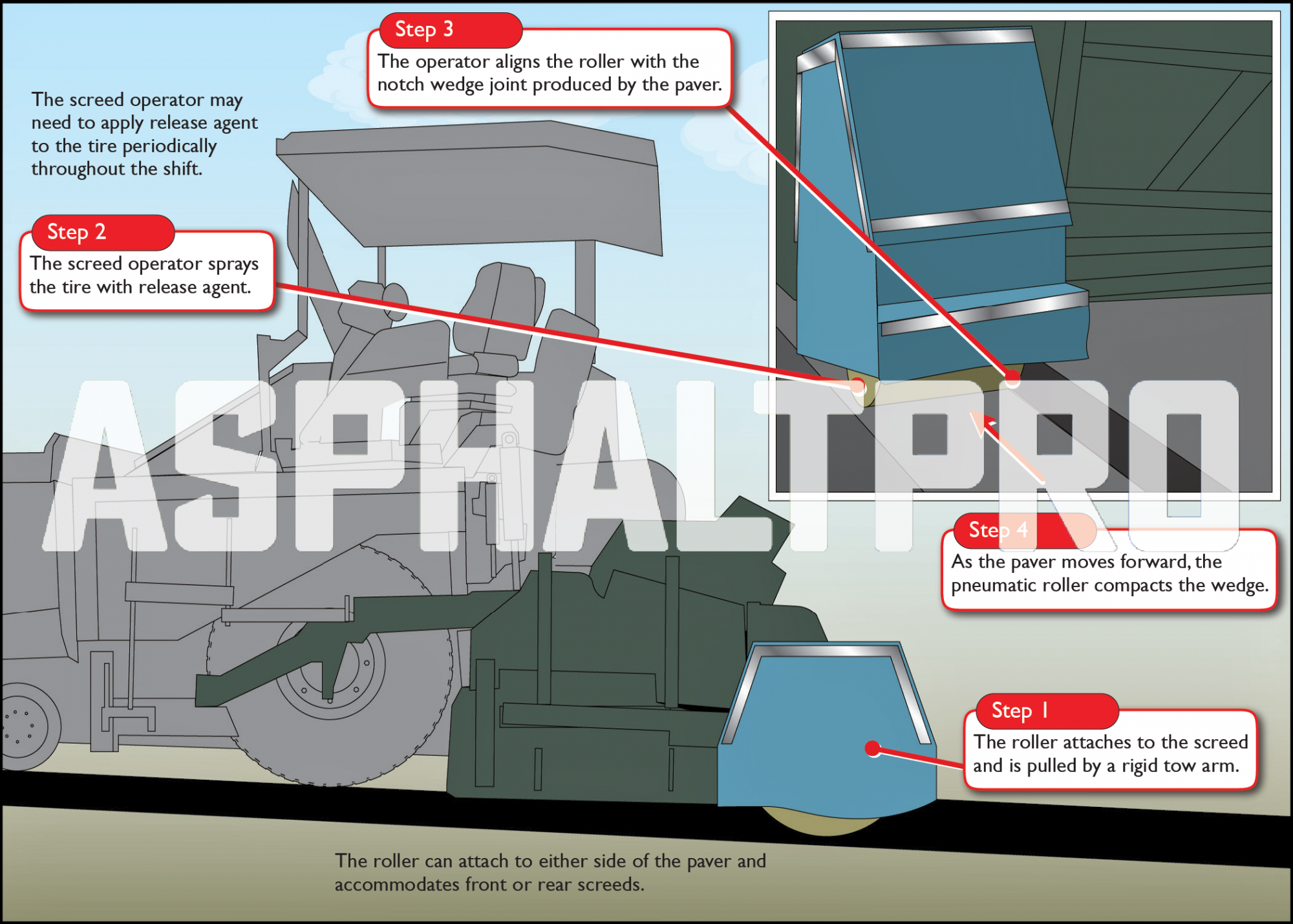

When state DOTS, like Connecticut DOT, started requiring secondary compaction of the notch wedge joint, Jerod Willow, proprietor of Willow Designs, East Berlin, Pa., developed a solution:Willow Designs’ notch wedge pneumatic roller. Although we don’t often get the chance to see notch wedge pneumatic rollers in action due to their heat retaining covers, here’s a look at how Willow Designs’ notch wedge pneumatic roller works.

First, the 450-pound roller is attached to either side of the screed by one crewmember. With its adjustable pull point, the roller can accommodate front or rear screeds. When the paver begins to move, the wide rubber tire roller heats to the appropriate temperature and is pulled directly behind the joint-building system by a rigid tow arm.

As paving begins, the screed operator uses a lever to spray the pneumatic tire with release agent from the roller’s pressurized tank. The screed operator may need to apply release agent to the tire periodically throughout the shift.

Then, the operator aligns the roller with the notch wedge joint being produced by the paver using the roller’s precise lateral steering adjustment. This offers the operator the ability to compact and stabilize the vertical notch of the joint with the sidewall of the pneumatic tire.

As the crew paves, the pneumatic tire roller compacts the wedge, ensuring the job meets secondary compaction requirements.

For more information, contact Jerod Willow at (717) 919-9828.