Use Drones for Materials Management

BY Sandy Lender

Know your legal limits, as well as your untapped potential, for sUAS in your asphalt business

When the use of small unmanned aerial systems (sUAS)—drones, in layman’s terms—first cropped up in the road construction industry, savvy contractors were using them to get images and footage for marketing purposes. Like children playing with their fathers’ tools, some of those contractors bought pricy drones, clipped digital cameras to their platforms, and watched thousands of dollars fly off into the sunset when faulty equipment tripped some un-researched trigger.

That is not a financially responsible or environmentally friendly way to do business. The Federal Aviation Administration (FAA) has something to say about it with permitting and privacy regulations. And there are more uses for drones than taking pretty pictures to submit to an awards committee, the most robust of which is materials management. Let’s take a quick look at a couple “easy” uses and then get into the nitty gritty.

Launch a drone over your stockpiles to get data. Image courtesy Trimble, Sunnyvale, California.

Track, Get More Jobs

A gentleman in the southeast, who wishes to remain anonymous, has purchased two drones for use in his asphalt operations. “The first one I purchased was to take weekly process pictures over my projects that are under construction. I paid about $8,000.” By grabbing in-progress images and video, this owner has not only updates for the project owners, but also has teaching and training material for his crews.

“I purchased the second one for $26,000, plus another $5,000 for the software,” he shared. This second drone does more than take pictures for him. “I can survey with the drone for as-builds, and cut and fill calculations for excavating of a project.”

Before the job begins, the use of drone technology can come in handy. When your estimator needs a snapshot that Google Earth can’t provide, grab the image with the camera on your drone. When you need proof of your job’s completion from an aerial perspective, use the camera on your drone rather than hiring a photographer to go up in a helicopter on the next weather-conducive day. When you need a marketing video for your YouTube channel, use the camera on your drone to film your crew paving the latest stretch of Interstate. You get the idea.

By using the image-capturing functionality of a drone, you open up marketing opportunities that will lead to exposure to new customers.

The owner programs the AV-900 hexcopter for its mission to take overlapping images of the stockpiles when using the drone for the purpose of determining stockpile volumetrics. Photo courtesy AirGon, LLC, Huntsville, Alabama.

Plan Your Plant Maintenance Points

For asphalt plants, scheduling maintenance is a questionable use of drone technology. Our ground personnel take care of that with close-up inspection. Can a picture-taking drone do the same job? Right now, our competition does it.

Jeff Meeker of Meeker Equipment, Belleville, Pennsylvania, shared that there are members of the Portland cement industry using drones for inspecting concrete plants. They send the drone into the tower to get pictures rather than sending a worker into the dangerous environment.

Apply the concept to our industry. When the manlift is down at your stationary asphalt plant, send the drone up to get a picture of potential maintenance points at the top of the baghouse, the drag conveyor, etc. Routine maintenance can’t take a break because the scissor lift is out or a member of ground personnel is on the D.L. At your portable asphalt plant, you can employ the drone as part of your daily walk-around to speed up your start-up routine. Rather than sending a guy to the top of the batch tower, send the drone. Look at the image it captures. If everything’s a-okay, you’re ready to start the day. If the image shows something out of place, you should investigate further.

An area where there’s no question that drone technology speeds up the operation while increasing accuracy is in materials management.

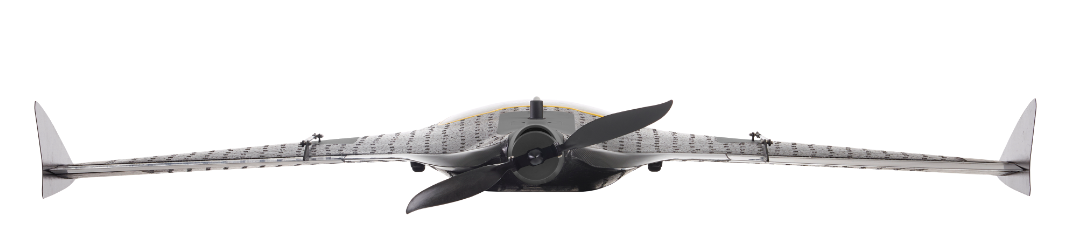

The ZX5 from Trimble Navigation, Belgium, can get into small spaces to grab data. Photos courtesy Trimble, Sunnyvale, California.

Streamline Your Stockpile Volumetric Analysis

A plant manager in the northeast, who wishes to remain anonymous, hopes to use his company’s drone for capturing images of the overall operation and of the stockpiles for record-keeping. His goal is to select a product to complement the drone he researched and purchased in June of 2015 that will help him analyze the data he gathers through the drone’s captured images. Considering he needs to capture real data from stockpiles four times a year, this is a real time-saver he’s adding to his toolbox.

“What I am looking to do is stockpile inventory,” he said. “I want to create 3D models of the stockpiles and that takes three to four days with a measuring wheel and GPS.”

Using the drone to map and photograph the stockpiles instead, and then feed the information to a software program, could potentially save him copious amounts of work and time.

Larger producers and quarry managers will find a cost-saving use for drone technology in one of the metric mapping kits from AirGon, LLC, of Huntsville, Alabama. First, let me explain that AirGon is a subsidiary of the GeoCue Group, which has been providing workflow and production solutions for sensor-based mapping since 2003. The company has been providing tools and technology used in creating mapping products from manned aircraft sensor data. AirGon offers a number of packages, including the AV900-MMK, to assist the owner in collecting and analyzing stockpile data multiple times per year. We’ll look at that example specifically.

Evan Smith of AirGon explained that the producer who is comfortable outsourcing his data management can hire AirGon to come in and do the work of gathering and analyzing stockpile volumetrics. Other producers will elect to do that work internally; they can purchase one of AirGon’s kits, attend training and then perform the work in-house.

The workflow to obtain volumetrics with the AV-900 MMK goes like this: The owner first places survey ground control points in the quarry or material yard for ensuring accuracy and tying to a reference system. From there, he plans the mission, which means he programs the AV-900 MMK Mission Planner software to fly the drone in the pattern he desires. The AV-900 hexcopter then flies itself along the flight lines and triggers the on-board camera, taking a series of overlapping images. Those images are used to create a point cloud that forms a visual 3D model using PhotoScan. From that image and point cloud data, the owner can produce output analytic data such as volumes and contours of the materials on the property by using AirGon’s LP360 analytic software.

Smith explained that AirGon’s Amazon Web Services cloud-hosted data management and delivery system, Reckon, gives producers context and volumetric results. “Reckon streamlines the process of requesting, gathering and delivering data for multiple stockpiles or the whole site,” he said. “It’s expensive to execute manned flights to do this once a year and end up with massive write-offs. The drone can do this several times a year and provide more frequent, more complete data.”

The UX5 and ZX5 UAS solutions from Trimble Navigation, Belgium, provide aerial data for various uses, including at stockpiles. The Trimble UX5 includes a 24-megapixel camera. The Trimble ZX5 is a multi-rotor aircraft that grabs data for everyday jobs, even in tight places. It comes with a 16-megapixel camera, which is designed to get high quality aerial pictures at image resolutions down to 1 mm.

The Business Center—HCE (Heavy Construction Edition) Photogrammetry Module that Trimble offers features state-of-the-art image processing technologies that make it easy to process complete UAS mapping projects. Specialized computer-vision algorithms then give the results automatically, with minimal manual interaction.

Since late 2015, Topcon Positioning Group, Livermore, California, has partnered with the digital photogrammetric solution provider Agisoft LLC, St. Petersburg, Russia, to provide the Agisoft Photogrammetric Kit for Topcon—Professional Edition software for post-processing of data collected using the Falcon 8 and Sirius Pro UAS. What all that product language means is Topcon also participates in the stockpile management business through drone use.

Since late 2015, Topcon Positioning Group, Livermore, California, has partnered with the digital photogrammetric solution provider Agisoft LLC, St. Petersburg, Russia, to provide the Agisoft Photogrammetric Kit for Topcon—Professional Edition software for post-processing of data collected using the Falcon 8 and Sirius Pro UAS. What all that product language means is Topcon also participates in the stockpile management business through drone use.

The photogrammetric kit lets the producer fly his drone to get pictures/data; then the software goes to work with point-cloud editing and classification. It will export a digital terrain or surface model to a variety of formats—depending on what the owner needs—including 3D models and full measurement analysis tools.

Planning unmanned drone flights takes minimal work when a company like AirGon is there to assist. AirGon’s Smith said his company also helps customers file the necessary paperwork for 333 exemptions, as does Trimble. In fact, if you elect to have Trimble do the work on-site, the clearances are covered. Erik Arvesen, the vice president of Trimble Geospatial Division released this statement:

“We are pleased to be among the first companies to receive an exemption from the FAA authorizing commercial operation of UAS. This decision reflects Trimble’s efforts to responsibly operate its UAS business in the U.S. while the FAA addresses air safety issues in opening the National Airspace System (NAS) for commercial UAS operators on a broader scale. Trimble will continue its efforts to support the FAA’s decision-making process and to provide opportunities for our customers to safely use the UX5 to capture accurate geospatial data for a wide range of applications.”

To employ any of the time-saving, cost-saving or PR-enhancing strategies mentioned above, the asphalt professional considering use of a drone in his operations will want to brush up on the law.

The packages that companies offer basically process the digital images that the drones capture to generate 3D spatial data. Different software programs present the information to the owner in different ways, but the point is to let you see how much material is in your stockpiles within a number of hours, rather than manually measuring and figuring the data on your own over a course of days or weeks. Photo courtesy Topcon Positioning.

Avoid Fines, Prison Time

To use a drone for marketing or other work-related purposes, you will need to petition for exemption from Section 333 of the FAA Modernization and Reform Act of 2012. That act prohibits the use of sUAS for commercial operations. In fact, there are four specific items the FAA lists as “main requirements” you will need to operate unmanned aircraft in a business capacity.

- a Section 333 grant of exemption, which will automatically give you a 200-foot nationwide Certificate of Authorization (COA) with certain restrictions around airports, restricted airspace and densely populated areas;

- a Certificate of Waiver or Authorization (COA) that is specific to the airspace of your operation;

- an aircraft registered with the FAA; and

- a pilot with an FAA airman certificate

Yes, those are the requirements for an unmanned drone. As of Dec. 21, 2015, FAA’s final interim rule (FIR) was in full effect, requiring anyone in possession of a drone to register it—at a cost of only $5. Meet the March 31 deadline or face a penalty of up to $250,000, according to www.faa.gov. Within the FIR, it states that an estimated 1.6 million sUAS were to be sold during 2015:

“With this rapid proliferation of new sUAS will come an unprecedented number of new sUAS owners and operators who are new to aviation and thus have no understanding of the NAS [National Airspace System] or the safety requirements for operating in the NAS.”

To that end, FAA wants full and complete records of all drones and model aircraft flying around.

According to the FAA website, “Under current regulations, a petitioner requesting a Section 333 exemption is advised to make the request 120 days prior to the date they anticipate [needing] it for operations.” The good news is the companies selling UAS and software want to help you get registered and certified to use their equipment. They can help you. If you’re going it alone, here are some sites where you can get guidance.

- There’s an app for that! FAA has released the “B4UFLY” smartphone app. Check it out at faa.gov/uas

- http://knowbeforeyoufly.org/for-business-users/

- http://uavcoach.com/drone-certification/

- http://www.hse-uav.com/faa_guidelines_for_petition_of_exemption_under_section3333.htm

- https://www.faa.gov/uas/media/model_aircraft_spec_rule.pdf

The UX5 HP from Trimble Navigation, Belgium, integrates a GNSS receiver and a Sony a7R camera that captures images at 36 megapixels of high resolution. This matters when delivering orthomosaics resolution down to 1 centimeter and 3D models with up to 1,000 points per square meter. It all feeds into the system that provides the user an accurate model and plan for material use, field leveling or site planning. Photos courtesy Trimble, Sunnyvale, California.

Err on the side of caution and consider your use of a drone to be for commercial—business—purposes if you’re reading this article. The website of the FAA states clearly:

“Unless you are flying only for hobby or recreational purposes, you will need FAA authorization via a Section 333 grant of exemption to fly your unmanned aircraft system (UAS) for your business. This applies even if you are only flying to supplement or aid your business and not charging fees for doing so. For further information regarding the FAA’s interpretation of ‘hobby or recreational’ flying, please see the FAA’s Interpretation of the Special Rule for Model Aircraft.” (This direct link is included in the bullet-point list above for your convenience.)

Another regulation to watch out for is your proximity to an airport. If you will be operating the drone within five (5) miles of an airport, you are required to give the authorities at the airport and air traffic control tower prior notice of your operation, according to FAA.

This means you cannot send the drone up to get pictures of a potential job site’s conditions for estimating purposes if that site is alongside a regional airstrip until you have notified the airport operator of the date and time of your flight. If your asphalt plant is within five miles of an international airport, you cannot send the AV-900 hexcopter or the ZX5 multi-rotor drone on its mission around your site until you notify the airport authority and the air traffic control tower.

After you’ve given notice, be aware that your unmanned aircraft must be operated “in a manner that does not interfere with and gives way to any manned aircraft,” according to FAA. If a private plane veers off course, your few thousand dollars is worth nothing compared to the lives on board that plane. Down your drone, which shouldn’t be flying above 400 feet if you’re complying with rules and regs.

When filing for your 333 exemption, you will get a full education on these and other regulations to which you must adhere when flying sUAS for commercial purposes. Keep in mind, common sense prevails. The asphalt company’s new drone is not a fun, pricy toy; it’s a real tool for enhancing your marketing or data management points. Treat it as you would any other government-regulated device and you’ll steer clear of fines—and actual prison time—that would otherwise mitigate its positive effect on your business.