Superior Asphalt Wins 2017 Ecological Award

BY Sandy Lender

Superior Asphalt takes 2017 Ecological Award with planning, environmental commitment

During the National Asphalt Pavement Association (NAPA) midyear meeting in Boston July 9, 2018, a ceremony honoring Operational Excellence Award recipients recognized the years of environmental stewardship built into the Dutton plant of Superior Asphalt Inc., Grand Rapids, Michigan. The company won the 2017 Ecological Award, not just for streamlined production facilities that improve productivity and safety, but also for demonstrating the asphalt industry’s concern for environmental issues. Those issues are near and dear to President and Founder Jeff Kresnak’s heart.

In addition to a retention pond to capture stormwater, the Superior Asphalt team has included berms and green areas around the plant. The facility is paved on a grade to direct the water.

Kresnak’s love of nature is reflected in the beautifully landscaped Dutton plant site; his sense of responsibility for protecting nature is reflected in his regard for the next generation. Look at his actions to see his philosophy at work.

First, Kresnak personally takes the time to strategically educate the next generation about nature and how we must continue to care for our world.

“Where the Red Fern Grows is the best movie that every kid needs to see,” Kresnak said. “I take copies of the movie to school districts for the fifth and sixth grade classes. It has everything good wrapped up in it from good morals, family values, work ethic, nature and story.”

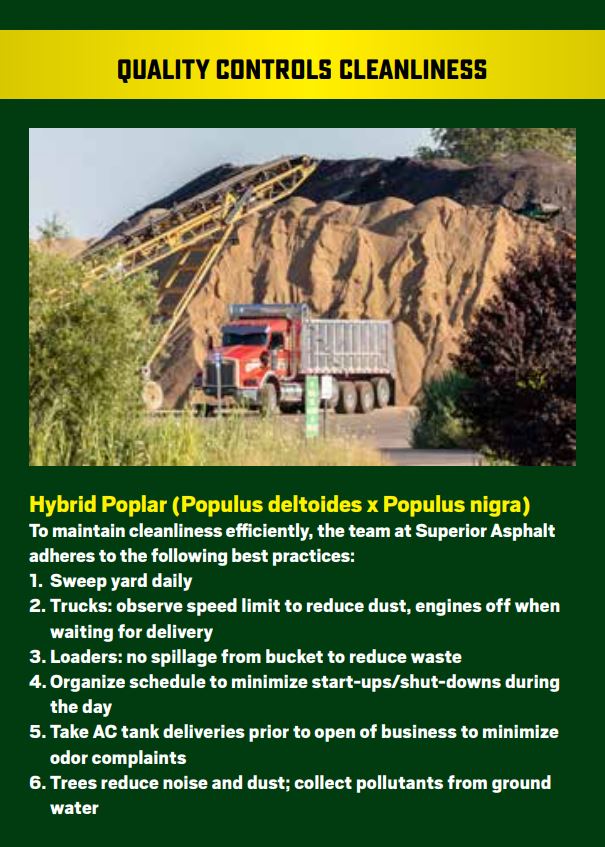

The Dutton plant is a Gencor 300 TPH drum. Quality Control Supervisor Nate Voriganti said the plant typically runs between 80 and 85 percent capacity with zero blue smoke. Minimizing starts and stops minimizes waste.

Second, Superior Asphalt personnel took the time to strategically select and plant over a thousand trees at the Dutton site.

“We put in 100 to 150 different spruce trees,” Kresnak said. “On the perimeter we put in approximately 500 hybrid willows and approximately 500 hybrid poplar trees. We tried to surround the plant with beauty and trees. They grow fast… We’re trying to make it look like the plant’s in a forest. And what a lot of plant owners need to know is this: The willows and poplars on high wind days stop the dust particles.”

At the Dutton plant, a number of spruce trees were planted as more mature trees, balled and wrapped. Kresnak said any large nursery in your area will have such good stock available. As for the seedlings: “You can go online and buy the seedlings for under two dollars a piece,” Kresnak said.

Superior Asphalt’s President Jeff Kresnak said, “I’m a fussy, neat guy. I want my plants to look the way my paving jobs look. We don’t leave crumbs behind.”

NAPA management pointed out the native spruce trees require little water, saving energy and resources in the long run. As the trees grow, they work alongside stone signage and hardscaping sourced from the plant’s Portland, Michigan, operations to screen the plant from its neighbors in an industrial cul-de-sac.

Stopping dust particles is a hot topic these days. Kresnak advised plant owners that the best way to keep dust down is to pave the plant site. “Both of our facilities are 100 percent paved on a grade to direct the water.”

This helps with the control of stormwater runoff as well. “The cleaner you keep your facility, the less stormwater problem you’ll have,” Kresnak said. “When stormwater comes, you can’t direct everything. We have one 2-acre retention pond at the Dutton plant. We have two smaller retention ponds at the Lansing plant.”

“We rely on NAPA for the tests of what amount of RAP is good for the mix,” President Jeff Kresnak said. Quality Control Supervisor Nate Voriganti shared the drum is designed to run up to 50 percent RAP, but they typically run about 25 percent.

Quality Control Supervisor Nate Voriganti added they have included berms around various stations and a green area around the plant and retaining pond. He said they use porous asphalt in the city of Grand Rapids and in their parking lots.

“Where we do our truck washout, if there’s any clay or dirt that comes off the trucks, we’ll scoop it up and take that to our rubble pile,” Kresnak said. “Every day we run our brooms. At each facility we run a skid steer broom getting into the small spaces, under the drum, that kind of thing, and getting the large areas with a loader broom. We have buckets on the units to capture the dust particles and those go up to our RAP piles.”

The cleanliness seen around the plant extends to the lab. Both the Dutton and Lansing plants have fully loaded labs and both are accredited with Michigan Department of Transportation (MDOT) and with federal specs.

“Nate runs both labs,” Kresnak said. “He’s highly respected in the industry and has been working on asphalt designs for 30 years. He’s extremely conscientious that the labs are spotless and the designs are on the money.”

The Dutton plant participates in round robin testing and handles both plants for nationwide tests with the American Association of State Highway and Transportation Officials (AASHTO). “When we do tests, they are submitted nationally,” Voriganti explained. “The results assure that our testing procedures are in line with the rest of the country.”

Kresnak shared that it wasn’t a stretch to get the Dutton plant’s lab accredited. “It’s fairly easy when you have the right equipment and qualified technicians. We have up to date computer automation systems in place. Our technicians have extensive knowledge of procedures. MDOT performs lab assessment once every two years. Nate Voriganti is our quality control supervisor and is assisted by Joe Weist. Nate has been with the company for 10 years and Joe 4 years.

Stacking conveyors build piles of material.

“Nate and Joe make a great team,” Kresnak continued. “They are self-motivated and stay up on all the current technologies, materials and procedures. We don’t get many complaints about the performance of our material. We have many repeat customers and referrals because of their commitment to quality.”

Kresnak explained the team’s commitment to quality and cleanliness are things he’s proud of. “We clean every single day,” he said. “It’s spotless, which is really hard in this industry, especially when we get busy. It’s just like keeping up a house. The tables are cleaned out every night. The floors are swept and mopped every night. That’s where we start.”

They also keep an eye on the consistency of incoming materials. “If you solely focus on outgoing material, you’re already too late. Communication with the plant operator, Tony Stepek, is key. Communication starts 24 hours before a job. We also keep pristine records regarding the material in our yard and mixes.”

From left: Quality Control Supervisor Nate Voriganti, President Jeff Kresnak, and Jeff’s youngest daughter Sara Kresnak

Kresnak had high praise for his plant operator. “Seriously, he’s the best plant man in the United States of America. He’s diligent, precise, a hard worker, loyal. He’s the kindest, most warm human being I’ve ever met. He’s worked for us about 10 years; came on when we opened our first asphalt plant. He’d been in the industry 15 years before.”

Of course the plant can’t run without a good ground crew, and Kresnak spoke highly of Tom Brower, who has too many jobs to have only one title. “Tom takes excellent care of keeping the plant clean and the area surrounding the plant clean. He’s a strong, diligent worker. He cares. And he does it all. You’ll see him doing everything from running the loader to the sweeper to a truck to anything the plant needs. He’s so diverse.”

As you can see, Kresnak has a business philosophy that melds with his environmental philosophy. He’s taking care of the world around his site as well as the people working the site. “It’s actually simple,” he said. “Maintain a super clean business all the way through. Landscaping, asphalt crews, the office, bookkeeping. If you keep all those areas clean, it’s hard to fail. Then make sure you’re sharing the profits and earnings of the company in the fairest way possible.”

Not every plant owner planned to pave his or her entire site before starting business. Not every plant owner has the manpower to plant 1,000+ trees next spring. But Kresnak had an idea for each plant owner interested in improving his or her environmental stewardship, or interested in reaching for an ecological award: “Stand out in front of the plant and ask themselves if this is how well they take care of the outside of their own house. Is this how well they take care of the inside of their own house? And would they mind if this plant was 200 or 400 feet from their house? That’s how we improve.”