Paving Rated 5th Most Dangerous Job

BY AdvisorSmith

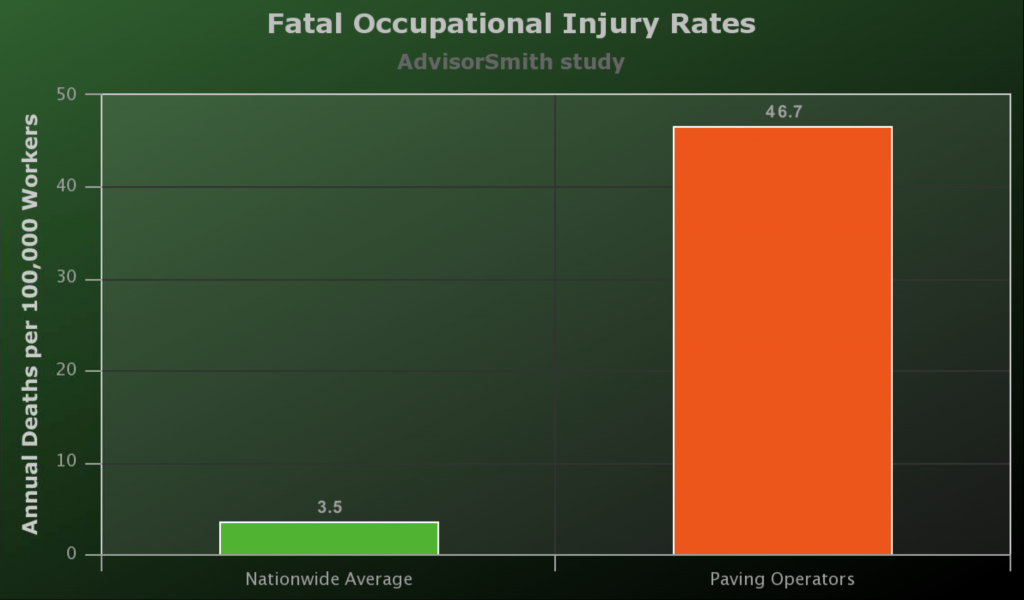

Paving, surfacing and tamping equipment operators have the fifth most dangers job in America, with a fatal injury rate 13 times more dangerous than the average job. Here are three ideas to keep your crew safe out there.

Paving, surfacing and tamping equipment operators have the 5th most dangerous job in America, according to a recent study by the small business experts at AdvisorSmith. The study analyzed occupational fatality rates among 384 professions using data from the Census of Fatal Occupational Injuries published by the U.S. Bureau of Labor Statistics. Injury data was adjusted by the employment in each job, and fatal injuries were averaged over a five-year period.

The average fatal injury rate was 3.5 per 100,000 workers for the average job, while the rate was 46.7 per 100,000 workers for paving operators, making the profession 13 times more dangerous than the average job.

The study also found that self-employed workers were four-and-a-half times more likely to be killed on the job than workers who work for employers. This is due to the fact that most employers implement safety and training programs to reduce the risk of employee injury.

According to Adrian Mak, who writes about small business insights and success for AdvisorSmith, the most common cause of death for paving operators was transportation incidents. For paving operators working in the highway or road context, a common cause of accidents was being hit by paving or construction equipment, or by other vehicles that inadvertently enter the construction zone.

A number of different forms of human error can lead to fatal occupational injuries for paving operators, including carelessness, fatigue, being distracted, or drugs and alcohol. Implementing a comprehensive safety program can help reduce the risk of injury or death.

Traffic Safety

As traffic crashes are a primary cause of death for paving professionals, implementing an effective traffic safety program is key for reducing occupational injury. Make sure that your work zone has highly visible signs and barricades to clearly signal to the traveling public to drive cautiously. Cities and states have their own regulations regarding traffic controls in their locality, and the Federal Highway Administration also has a Manual on Uniform Traffic Control Devices (MUTCD) for companies to follow.

It’s also helpful (and sometimes required by law) to have safety personnel and flaggers on site. If operating at night, there will often be regulations requiring your work site to have adequate lighting. All workers must wear properly reflective safety vests and other gear so they can be easily seen by other drivers.

Equipment

The zones around and between paving equipment can be very dangerous for paving operators and their teams. When getting on and off paving equipment, make sure that the machine floor and stairs are clear of slip hazards. Also, keep handrails, pedals, and knobs clean of oil and grease. Make sure that grab rails are easy to reach and never jump off a machine.

https://theasphaltpro.com/cross-train-your-crew/

When backing up paving equipment, it is imperative to check that no one is behind the machine. An especially dangerous area is between the hauling unit and the paver, and workers must be trained to never work or stand in that area.

Overhead obstructions are also a key concern for a paving operation. The paving site may be near electrical poles or lines that construction equipment can easily knock down. Make sure that the entire team is aware of all potential obstructions on or around the site.

Training

It’s important to implement training programs and policies around the paving and construction equipment. Reading the manual and conducting period training and re-training for the equipment operator is key. Often the manual will highlight specific safety concerns about the paving equipment. Be sure to review these with your team, and have an experienced operator train a new operator when they use equipment for the first time.

Walk-around and inspect equipment with the operator and work crew before each shift. Be sure that all warning labels and signs on equipment are clean and easily visible. Replace any decals or warnings that are damaged.

For more information, read the original study here: The Most Dangerous Jobs in America.