New Asphalt Paving Equipment: November 2016

BY AsphaltPro Staff

AsphaltPro takes you into the homestretch of the paving season in the south and gives you dreams of the upcoming season if you’re watching temperatures drop in the north, with a product gallery focused on the new technology and equipment that assists contractors in the paving and pavement preservation/pavement maintenance arenas. A few OEMs provided responses to specific questions about their new equipment this month. Check out the highlighted features of the products from BOMAG, Roadtec and Vogele.

The rubber track Cedarapids CR662RM RoadMix from BOMAG features a new 260 horsepower Tier 4 Final Cummins diesel engine, improved remix delivery augers that now feature hard-faced back sides to increase wear life, and patented Smartrac™ technology.

New from BOMAG

The Cedarapids CR662RM RoadMix paver and material transfer vehicle by BOMAG was launched in June of this year. Henry Polk shared that the product has the following benefits for the asphalt professional:

- The CR662RM RoadMix replaces the traditional slat conveyor delivery system inside the hopper with the Remix Anti-Segregation System counter rotating delivery augers to reblend the asphalt at the project site to eliminate particle and thermal segregation;

- One RoadMix machine offers two uses for the contractor: paver and MTV. Contractors can switch between a screed (for paving use) and swiveling conveyor system (for use as MTV) within a few hours;

- The machine maximizes utilization rates for the asphalt professional;

- It can be used on the base lift, even as an MTV; and

- It provides the contractor with a means to increase mat quality, density and uniformity.

Polk shared what he considered to be the product’s most attractive feature for the asphalt professional:

- The Cedarapids CR662RM RoadMix is the only machine on the market to offer dual purpose application – paver and MTV – while addressing segregation issues;

- It helps to lower overall operating costs by maximizing utilization rates;

- Its rubber track drive system vs. rubber tire drive on most MTVs lower ground contact pressures to a fully loaded 21 PSI, so it can be used on all paving lifts; and

- Addressing segregation at the last stage of the paving process helps to build better roads.

Polk suggested the following for asphalt professionals considering the CR662RM:

- The CR662RM offers dual-use to improve machine utilization rates and return on capital investment over traditional MTVs;

- If the contractor has a mainline paver, adding the CR662RM to the fleet will deliver more uniform temperatures across the mat and more consistent mat uniformity, so spec compaction densities can be achieved; and

- Operating costs are less. As an MTV the fuel consumption is less than half of conventional transfer machines. As a paver, the auger delivery system is proven to cost less to maintain than a slat conveyor paver.

- Use this to place the asphalt mat.

- For more information, contact Henry Polk at (309) 883-4988 or polk@bomag.com

The SX-6e has its Tier 4 Final engine.

New from Roadtec

The SX-6e from Roadtec was updated to Tier 4 Final version in the first quarter of this year. Kyle Hammon shared that the product has the benefit of performing soil stabilization and asphalt or full depth reclamation for the asphalt professional. Hammon shared what he considered to be the product’s most attractive features for the asphalt professional: “A 4-speed cutter transmission that allows the machine to operate at full engine RPM with different drum speeds. This feature allows the operator to quickly select the optimal cutter speed for his project without sacrificing engine power or devoting work hours to modification of the belt drive.” Hammon suggested the following for asphalt professionals considering the SX-6e: “The SX-6e is designed with the necessary cutter housing, weight balance, and drive system to maximize overall production and material quality. The availability of the Guardian™ Remote Telematics system also provides an enormous advantage toward maintaining productivity and limiting down time.”

Roadtec launched the CB-100 earlier this year.

The CB-100 from Roadtec was introduced in the first quarter of 2016. Hammon shared that the product has the benefit of sweeping “the recently milled asphalt surface, collecting the remaining fine material and conveying it to a dump truck. This process leaves a clean surface for placement of an asphalt overlay and allows the contractor to retain the valuable fine material produced by the milling process.” Hammon shared what he considered to be the product’s most attractive features for the asphalt professional: “A tightly enclosed brush housing and conveyor system that allows the machine to efficiently remove fine material from a milled surface and place it in a dump truck. This design limits material loss and leaves an excellent clean surface behind the machine.” Hammon suggested the following for asphalt professionals considering the CB-100: “The CB-100 is a heavy duty machine that is built to last. Its outstanding performance is paired with high strength, durable components to maximize performance, durability, and profitability for the owner.”

- Use this in pavement maintenance.

- For more information, contact Kyle Hammon at (800) 272-7100 or khammon@roadtec.com.

The new Super 2000-3i from Vögele is a 10-foot tracked highway class paver featuring the ErgoPlus 3 operating system and Niveltronic Plus automatic grade and slope control.

New from Vögele

The Vögele Super 2000-3i asphalt paver from Wirtgen Group was introduced to North America March 22, 2016, at the World of Asphalt in Nashville. Ken Snover shared that the product has the following benefits for the asphalt professional:

- The Super 2000-3i features a basic width of 10 feet and a maximum paving width of 28 feet. It has a top placement rate of 1,540 tph. The tracked Super 2000-3i is designed primarily for use in highway construction and large-scale commercial applications.

- With a powerful, 6-cylinder Cummins QSB6.7-C250 engine rated at 250 hp (186 kW @ 2000 rpm) and high-output hydraulic drives, the Super 2000-3i is fully equipped for robust applications.

- It is Tier 4 final emissions-compliant, and provides an excellent horsepower-to-weight ratio. Yet its fuel-saving ECO mode is sufficient for many applications. Even in ECO mode, the Super 2000-3i still has a full 234 hp at its disposal, while the machine generates even less noise when running at just 1,700 rpm.

- Niveltronic Plus, the exclusive Vögele system for automatic grade and slope control, was developed based on many years of experience in grade and slope control technology. This fully integrated system is optimally adapted to the machine technology of the Super series pavers. All wiring and connections, for instance, are integrated into the tractor and screed, effectively eliminating all risk of damage to these components.

- A large and practical selection of sensors permit versatile use of the Niveltronic Plus Whether for parking lots, traffic circles or highways, Vögele offers the right sensor for every job site situation. Sensors can be changed quickly and easily, for Niveltronic Plus automatically detects which sensor is connected, thus simplifying the configuration.

Snover shared what he considered to be the product’s most attractive features for the asphalt professional:

- The Super 2000-3i features an innovative and reliable drive concept for accurate tracking. All drive components, including the three-phase generator, are supplied from the central splitter gear box and operate at maximum efficiency. High-traction crawler tracks efficiently convert drive power into forward motion.

- A large cooler assembly ensures that the power unit always delivers its full output. With innovative air routing and a variable-speed fan, temperatures are continually maintained within the optimum range. A further advantage is that the machine can operate without difficulty in all climates.

- Because all hydraulic elements are supplied with hydraulic oil directly from the splitter gearbox, all pumps and valves are combined in one spot that is easily accessible for maintenance work. Even the generator for screed heating is flanged directly onto the splitter gearbox.

Snover suggested the following for asphalt professionals considering the Super 2000-3i:

- This new paver, which replaces the Vision 5200-2i in the Vögele lineup, introduces Vögele next-generation Dash 3 technology and its ErgoPlus 3 operating system to a highway-class paver specially suited for North American use.

- With ErgoPlus 3’s new mounting system, the paver operator’s console can be shifted even more conveniently and easily between the right and left sides of the operator’s stand. In addition, it now has a large color display that ensures good readability even in poor lighting conditions.

- All controls are clearly arranged. Paver functions are clustered in logical groups so operators find their controls just where they would expect them to be. On the ErgoPlus 3 console, all push-buttons are easily identifiable by touch even when wearing work gloves. Vögele’s Touch and Work principle means that once a button is pressed, the work begins. Functions are executed directly, without the need to confirm.

- Also, the main paving functions of the screed can be controlled using one of the two handy screed remote controls for each side of the paver for the Vögele VF 600 and VR 600 screeds. Intuitive operation is possible thanks to self-explanatory and language-neutral symbols.

- The remote controls can be securely stowed in the holders on the main screed, or on the ends of the screed extensions. The holders are magnetic, meaning that the remote controls are easy to grab at any time, giving the operator a large radius of movement so that he can always find the most effective working position in any paving situation.

- Use this to place the asphalt mat.

- For more information, contact Ken Snover at (615) 501-0600 or ken.snover@wirtgen-group.com.

The Load Lifter 5000™ Series for 2017 Ford Super Duty trucks was released this summer.

New from Air Lift

Air Lift, Lansing, Michigan, has released its new heavy-duty LoadLifter 5000™ and LoadLifter 5000™ ULTIMATE air spring series to support and protect Ford’s 2017 Super Duty F-250 and F-350 4WD pickups. The LoadLifter series works with the vehicle’s existing suspension to deliver up to 5,000 pounds of load-leveling capacity and is air adjustable to keep vehicles stable, level and comfortable, according to the manufacturer. Each kit includes exclusive Air Lift roll plates, which protect the air springs from sharp edges and increase load capacity up to 10 percent. The kits require no drilling into the frame and install in three hours or less.

- Use this for your work vehicles.

- For more information, contact Air Lift at (800) 248-0892.

New from Atlas Copco

The F1000 pavers from Atlas Copco, Commerce City, Colorado, feature new auger and tunnel systems.

Atlas Copco’s F1000W wheeled and F1000T tracked 10-foot pavers allow contractors to equip the units with either a center auger drive system or outboard auger drive system for a variety of applications. The pavers also can be equipped with Atlas Copco’s new tunnel extension system.

The 10-foot pavers can also include a hydraulic tunnel extension system along with the center drive auger system. The 22-inch wide hydraulic tunnel extension will automatically retract when screed extensions begin to retract to prevent collision. The hydraulic tunnel reduces excess head of material in the tunnel area and prevents asphalt from entering into track components.

The material flows through the Carlson front- or rear-mounted screed. A tractor-mounted 34-kW generator heats the screed’s full working width, which is as wide as 28 feet with the Carlson EZ R-2 screed.

- Use this to place the asphalt mat.

- For more information, contact Vijayakumar Palanisamy at (313) 248-9040 or palanisamy@us.atlascopco.com.

The Deutz 2.9 L4 diesel engine in Carlson’s CP75 II is designed to enhance fuel economy by 10 percent while providing 10 percent more torque, compared to its predecessor.

New from Carlson Paving

Carlson Paving Products, Tacoma, Washington, has upgraded the CP75 to a Tier IV Final platform to respond to changing regulations of emissions standards. The CP75 II’s Deutz 2.9 L4 diesel engine is designed to enhance fuel economy by 10 percent while providing 10 percent more torque, compared to its predecessor.

The CP75 II features the platform’s standard two-speed planetary system and screed-mounted controls. The CP75 II uses horizontal sliding damper doors to give operators 10 inches of ground clearance below the auger box, while allowing for narrow width paving up to 4 feet by closing the damper doors. It has a hopper capacity of 8 tons. It also features the Carlson high flow material conveyor, which uses 35.5-inch heat- and oil-resistant rubberized belts fixed to chain-driven slats to transfer material to the augers.

- Use this to place the asphalt mat.

- For more information, visit www.carlsonpavingproducts.com or call Tom Travers at (253) 875-8000.

New from Caterpillar

Caterpillar Inc. announced the availability of the PM620 and PM622 cold planers as of first quarter 2016. The half-lane milling machines are designed to perform controlled full-depth removal of asphalt and concrete pavements in a single pass. Both are powered by a Cat® C18 ACERT™ engine, a turbocharged, 6-cylinder diesel engine that provides 630 horsepower of gross power.

The machines are fully hydrostatically driven by two variable displacement propel pumps supplying oil to variable displacement motors on each track. Drive motors are piston-type and designed to automatically control displacement to provide maximum torque for work or greater speed for moving around the job site. A propel lever/steering joystick provides infinite control of the travel speed within the range. The machines have a propel system with a diagonal cross flow design for traction. The pumps drive opposing track motors, front to back and side to side.

The PM620 is equipped with a 79-inch-wide rotor and the PM622 is equipped with an 88-inch-wide rotor. The maximum cutting depth is 13 inches. The rotor is equipped with durable three-piece, quick release tool holders and carbide-tipped cutting bits arranged in a chevron pattern for maximum breakout force.

- Use this for pavement maintenance.

- For more information, contact your Cat dealer.

New from Chicago Pneumatic

Chicago Pneumatic (CP), Independence, Ohio, launched the revamped CPG 25 and CPG 45 generators in August of this year. Available in skid-mount and trailer-mount configurations, the new CP generators now offer the longest run time in their class, according to the manufacturer. The new CP generators are lighter weight than the previous versions. They feature the same design principles of CP compressors: trailers identical to the CPS 185 compressor; weatherproofing; and corrosion-resistant, sound-reduced, compact enclosures. Both models offer the same platform with a common engine cubicle and enclosure. The generators come with a standard five-year limited engine warranty on the Isuzu 4LE engine with DOC engine exhaust aftertreament. The CPG 25 offers 32.5 horsepower (HP), and the CPG 45 runs at 59 HP. A heavy-duty marine impregnated alternator has multi-voltage capabilities.

- Use this for additional power.

- For more information, visit cp.com.

New from Diamond Road

This summer, Diamond Road, American Fork, Utah, launched its Diamond Road Smoother, an all-in-one diamond tooth grinding system. It includes a profiler, computer system, water tank, cutting machine, brooms, vacuum system and directional arrow board on a towable trailer. The manufacturer estimates a quick set-up time of 2 minutes from transport to grinding and a working speed of up to 5 mph. The 8-foot grinding head works on both asphalt and concrete roads up to 0.5 inch deep without decreasing speed, according to the manufacturer.

The machine’s automated controls allow it to run based on a pre-determined road profile, and its long averaging arms with multiple pivoting wheels aim to level each surface defects.

According to the manufacturer, the Smoother can be used before thin overlays, chip seals and slurry seals to provide a smoother surface.

- Use this for pavement maintenance.

- For more information, visit www.diamondroad.com.

The new North Zone™ hard hat from Honeywell Industrial Safety is available in 17 colors and two suspension designs.

New from Honeywell

Honeywell, Smithfield, Rhode Island, launched its North Zone™ hard hat early August. The hard hat features patented suspension, multiple adjustment points and a rear comfort cradle. The hard hat is designed to fit the vast majority of head sizes, which directly supports worker safety—a comfortable hard hat will remain on the head, resulting in a better-protected and more productive workforce.

“Poor fit and discomfort are the top complaints of hard hat wearers, according to extensive customer research we conducted throughout North America,” Daniel Birch said. He’s the senior marketing manager for Honeywell Industrial Safety. The worker achieves a custom fit by adjusting the headband for height; the macro size adjust headband allows selection of small, medium/large, or extra-large circumference; and the easy grip ratchet enables precise tensioning.

The hat is available is 17 colors and in two suspension designs. Constructed of HDPE, the North Zone shell incorporates standard accessory slots for use with cap-mounted earmuffs and/or face shields. The manufacturer states the hard hat meets ANSI/ISEA Z89.1 2014 Type I, Class C, G and E as well as CSA Z94.1 2015 Type I, Class C, G and E safety standards.

- Use this for work zone safety.

- For more information, contact Honeywell Industrial Safety customer care department at (800) 430-5490 or (888) 212-7233.

New from LeeBoy

LeeBoy has rolled out the 5300 Series as the newest in its asphalt paving equipment line in 2016. The compact design offers versatility for the smallest of paving jobs to include cart paths, sidewalks, trenches, mill, patch and repair work.

The 12,700-pound paver has a 64-horsepower Tier 4 Final water-cooled diesel engine. The fully enclosed engine housing provides easy access for servicing and also results in low sound levels allowing for quiet operation in residential areas.

The unit comes standard with the LeeBoy Legend HD Mini Screed System. A smooth, seamless mat up to 9 feet wide can be produced with the standard bolt on screed extensions, according to the manufacturer. The hopper capacity is 7 tons. The 5300 can be configured to pave in a trench as small as 48 inches.

Some other features of the unit include: sliding operator control station to enable use from either side of the paver, heavy-duty undercarriage and track system, plus-1 dual joystick controls to provide forward and reverse direction with steering, single 13-inch conveyor controlled by automatic sensors, maintenance free internal spring-applied hydraulic release parking brakes and under auger cut-offs to provide the operator with precise control of the head of material at the main screed, and hydraulic extensions.

- Use this to place the asphalt mat.

- For more information, visit leeboy.com.

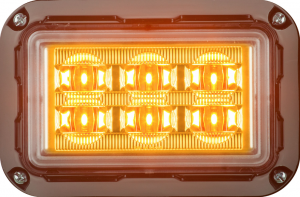

Optronics International, Tulsa, Oklahoma, has introduced its first line of LED directional warning lights for use on work trucks, or maintenance and service vehicles.

New from Optronics

Optronics International, Tulsa, Oklahoma, introduced its first line of LED directional warning lights in August of this year. The family of nine white and amber directional warning lamps was designed to meet SAE J845 Class II standards and for use on work trucks, maintenance and service vehicles, and to warn of traffic hazards such as a lane blockage or slow-moving vehicles.

The lamps all feature tough polycarbonate lenses that are sonically welded and watertight. Their IP67 rating designates the lamps as highly resistant to water and particulate ingress. The lamps employ a solid-state, surface-mount device (SMD) design that guards electronic components against moisture, shock and vibration. The lamps each feature 12 sync-capable flash patterns.

- Use this for work zone safety.

- Optronics products are available in the U.S. and Canada through the dealer network.

Drywell-style heating elements from PHCo are now available to be installed as new or retrofit equipment. PHCo also offers a drop-in heater option.

Updated from Process Heating Company

Process Heating Company (PHCo), Seattle, now offers its Lo-Density® rigid tubular drywell tank heaters for an efficient form of heat for asphalt and emulsion distributor truck tanks. With the Lo-Density heating system, the operator plugs the heater in at the end of the day, and it maintains the emulsion at the correct temperature overnight or over a weekend. The result is that the truck is ready to begin work immediately in the morning without waiting on burners to heat the material at the beginning of the shift. PHCo’s unique drywell-style elements reside inside the heater’s sheath. The low-watt density heaters dissipate controlled heat on the sheath, providing even heat distribution throughout the reservoir to prevent coking or damage of temperature-sensitive emulsion material. The drywell-style heating elements are easily accessible from outside of the tank, eliminating the need to drain the tank to service them. The tank heaters are now available to be installed as new or retrofit equipment, and PHCo also offers a drop-in heater option.

Lo-Density electric heat can reduce operating costs for distributor trucks, according to the manufacturer. The overnight maintenance of asphalt/emulsion temperatures via electric heat requires less energy and results in lower costs than using LPG or diesel burners to raise the material to the correct temperature.

UL-listed controls located on the distributor truck fender offer easy-to-use complete automation of temperature regulation. The main indicating temperature control regulates the product temperature and includes a high-limit control for safety. The main disconnect and individually fused heat circuits provide overcurrent protection. All components are mounted and prewired in a UL-listed, weatherproof enclosure.

Each heating unit is designed for the individual application, and can be customized to meet the specific needs of the manufacturer or user for sheath diameter, number of elements and sheath length, or applications. Rigid heaters can be made from mild steel or various grades of stainless steel, depending on the application. The sheath wall thickness ranges up to 0.3 inch for durability and corrosion resistance. The heating units are suitable for a kilowatt rating of up to 1,000 kW; voltages up to 600 VAC, in single or 3-phase; and watt densities of 3 watts per square inch of heater surface being standard. Terminal enclosures come standard with moisture resistance. PHCo offers an industry-exclusive five-year element replacement guarantee.

- Use this for pavement maintenance.

- For more information, contact PHCo at (866) 682-1582.

The XL 80 Power Tail trailer is the newest launch from XL Specialized Trailers, Manchester, Iowa.

New from XL Specialized Trailers

XL Specialized Trailers, Manchester, Iowa, has introduced a new trailer to their lineup as of August this year, with the XL 80 Power Tail trailer. Designed for transporting medium-duty construction equipment, the trailer features a hydraulic fold-under flip tail ramp for quick loading and unloading of hard-to-load equipment. With a load angle of 10 degrees, the hydraulic tail is equipped to handle man lifts, rollers, forklifts and paving equipment. The XL Power Tail is rated at 80,000 pounds overall and 50,000 pounds concentrated in 10 feet. The tail has a lifting capacity of 25,000 pounds for loads centered on the main platform. The tail is comprised of two sections—an 8-foot, 8-inch platform ramp and a 60-inch flip tail. Lug-style hinges are designed to prevent debris from accumulating, keeping both hinge points clean.

This model offers standard features to make drivers’ jobs easier: a hydraulic pop-up ramp connecting the deck to the gooseneck, a foot hole and grab handle on each side of the gooseneck for climbing onto the deck, an 18,000-pound hydraulic winch with a two-function wireless remote and an air kick-out for hauling inoperable equipment or static loads. Raised Apitong and quarter-inch self-cleaning star traction decking, D-ring stake pockets, chain slots and a work light add convenience.

The XL 80 Power Tail is available in two lengths: 48 feet or 53 feet. There are customized options to choose from such as an 8- or 10-function remote, workaround pulley for winch cable, steel tread plate on the flip tail and pop-up ramp, and various winches to customize the trailer for your specific needs.