How to Maintain Your Screed

BY Sandy Lender

To pave a smooth mat, a number of variables must be managed, including the condition of the paver. Paving Consultant John Ball, the proprietor of Top Quality Paving and Training, Manchester, New Hampshire, shared that the most important part of the paver to keep in tip-top shape is its screed. If the screed is unable to heat correctly or in some other state of disrepair, your crew has a problem. Let’s look at how to maintain this vital component.

The eccentrics on the screed have a hydraulic hose that you shouldn’t have cause to worry about for the first two to three years of its life, but it can grow brittle with age. The vibration of the eccentrics could cause the hose to break and spill hydraulic fluid, so stay aware of its condition.

The slide-outs on the extensions have seals that you will want to keep an eye on. Those seals will leak hydraulic fluid if you allow a build-up of material to clump on the extensions and get dragged in and out of the main structure. The material will wear on the seals and compromise their integrity. After each shift, use a biodegradable release agent and soft rag to wipe down parts of the extensions. If necessary, use a putty knife to scrape material loose. Keep these sections clean and free of clumps.

One of the greatest innovations for screeds is the move to electric heat, but that means you want to keep an eye on the circuits. Don’t assume each band is heating the plates to their appropriate temperatures, and then take off down the lane. If one endgate won’t stay hot, it will drag down the mat, leaving a trail of trouble for your lute man and roller operator. Instead, begin each shift by checking each plate’s temperature with an infrared gun. If something—such as heavy, blowing rain or the vibration of the eccentrics wiggling wires loose—has caused a short circuit, have your electrician tend to it.

Ball said the most important part of the screed to keep an eye on is the plate. You want to check the screed itself to make sure it’s able to heat properly, all the way across. You also want it to be smooth and straight, not warped or gouged. Think of the screed plate—and the plates on the extensions—like an iron. If the iron has cold spots or divots, you won’t get a nicely ironed shirt. The same is true of the screed and the mat you wish to get paid to place.

Look at the smooth, even mat behind the main screed and extension here. This is the quality you want to see each and every job. Notice the blue arrow points at a spray bottle of biodegradable release agent that the screed operator can access easily throughout the shift. He doesn’t have to go looking for it when a clump of stuck material is causing a drag mark in the mat; it’s right there at his fingertips to help him solve any problem quickly.

The yellow arrow in this picture calls your attention to the underside of the main screed and the extension. Look at how smooth and perfectly clean and shiny those plates are. That’s the way your screed must be to prevent drag marks, divots and imperfections in the mat. The yellow star draws your attention to the clean and well-maintained sliding endgate. This component’s easy motion keeps the screed from shaking or lurching during operation. You want all moving parts to move smoothly.

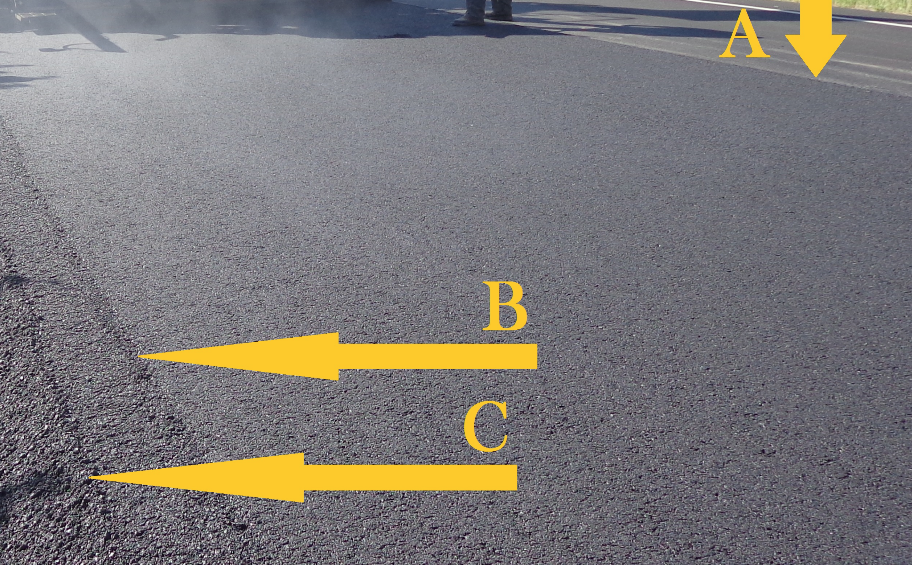

In this picture, the arrow marked A shows that the crew is matching the longitudinal joint beautifully. The mat is picture-perfect all the way across the right extension and main pull until we get to the left extension, which did not have a properly heated screed plate or endgate. Arrow B shows where the “cooler” extension begins. Arrow C shows where the “cooler” endgate is not running smoothly down the pass. You can see the direct effect to the mat of an electrical problem in the screed. When the crew stops to address the electrical problem, the roller operator will have some extra work to do to get adequate compaction.

In this picture, you can see the difference between the mat being placed by the main screed plate, which is heated correctly, and the left extension, which is experiencing an electrical short. The savvy crew will stop to let the electrician correct the electrical problem, heat the entire screed properly, and continue for best performance.