How to Use Water Absorbers

BY Scott Grossbauer

Free water is probably the single biggest cause of fuel system failure. Original equipment suppliers require that zero free water reach the high pressure common rail (HPCR) fuel system. Water absorbers are the only sure way to prevent free water from being dispensed into your equipment. Eliminating water will reduce rust, corrosion, wear, fuel degradation and other damage. It will also help prevent denied warranty claims.

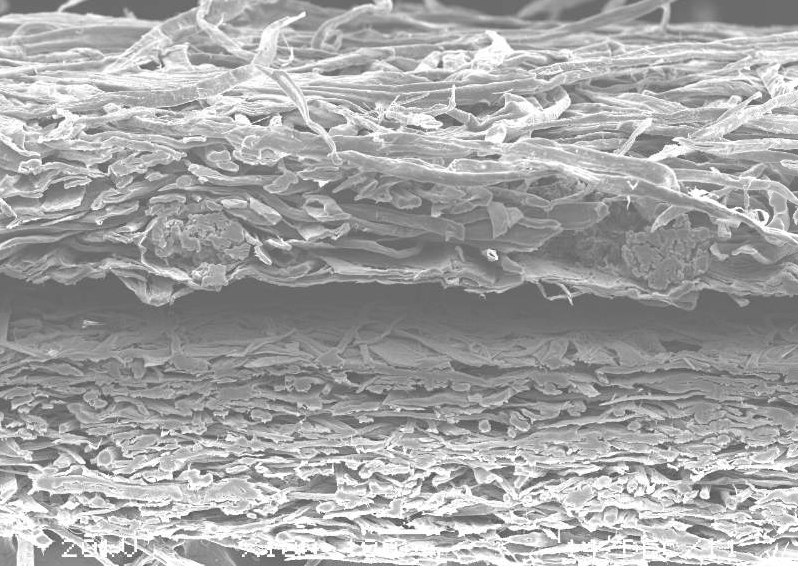

Regular/particulate filters and water absorbers do two distinct jobs; the first removes hard particulate from fluids while the second removes free water. The medias are different, each designed to optimize the specific job at hand. For example, a particulate filter made of synthetic fiber should have fibers of consistent size and shape to allow for specific pore size control and the maximum amount of contaminant-catching surface are. The result maximizes both filter efficiency and dirt-holding capacity.

Water absorbers use polymer technology with a high affinity for water absorption. This media is designed to remove free water from petroleum-based fluids. Unlike coalescing media, absorbent media isn’t disabled by the surfactant in ultra-low-sulfur diesel (ULSD).

The DBB0248 water absorber may be installed in combination with particulate filter(s). It fits all Clean Solutions heads and manifolds. It is also included in the X011449 Clean & Dry filter kit. When plumbing the absorbers together with particulate filters, you connect them in series. The fluid should flow first through the particulate filter to clean it, and through the water absorber second to remove free water.

The absorber is installed in the secondary position because the particulate filter is much better at catching and holding dirt. Dirt will not reach the absorber; therefore, it will last much longer. In addition, this enables the differential pressure gauge on the absorber to work as a diagnostic tool alerting when there is a water problem in the tank so you can take appropriate measures. If the absorber were plumbed first, it would load with dirt and water, plugging faster and losing its diagnostic capability.

Scott Grossbauer is the global director for Donaldson Company, Inc., of Minneapolis, Minnesota, clean fuel & lubricant solutions division.

Scott Grossbauer is the global director for Donaldson Company, Inc., of Minneapolis, Minnesota, clean fuel & lubricant solutions division.