Gencor’s Green Machine

BY AsphaltPro Staff

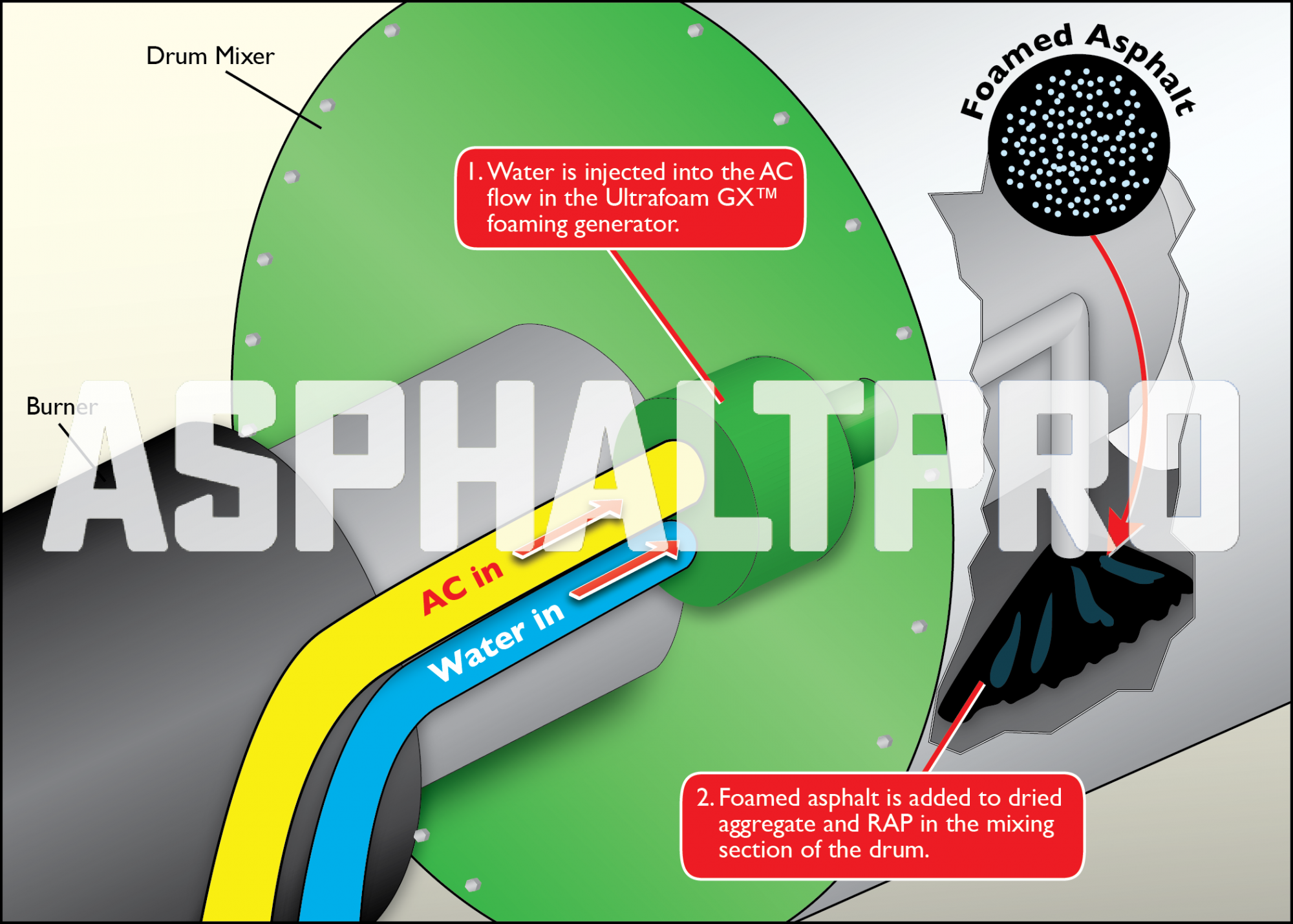

The Ultrafoam GX2 from Gencor, Orlando, is designed to inject steam into the foaming process using only the energy of the pump or head supplying the liquid asphalt cement (AC) and water for warm-mix asphalt (WMA) production. Here’s how it works.

A small percentage of water—1 to 2 percent by weight—is injected into the center of the AC flow by a positive displacement water pump. According to the manufacturer, the pumping system provides all of the mixing energy. The Ultrafoam GX2’s centrally loaded water valve opens when the pressure of the water is impressed behind the valve.

A diaphragm plate introduces and directs the flow—and rate of flow—of AC to the process, and a special valve design prevents the AC from back-flowing into the water piping system. The fingers of the diaphragm deflect, allowing for increased flow area as the flow of the AC increases. All the while, the AC flow stream is directed toward a center nozzle.

The AC flow converges to the center of the injection point of the water. According to the manufacturer, this allows the Ultrafoam GX2 to maintain a perfect ratio of AC and water at all production rates and creates small, stable bubbles for consistent asphalt foaming.

For more information about the Ultrafoam GX2 technology, contact Dennis Hunt at (407) 290-6000 or visit www.gencorgreenmachine.com.