Check Out Fracking Opportunities

BY Holly Bellmund

For hydraulic fracturing, fluids and proppants are forced under pressure down a hole to stimulate the source rock to release oil and gas. This has been a widely adopted commercial practice since the 1980s with explosive growth beginning in 2010 when horizontal drilling was combined with hydraulic fracturing to produce oil and gas from the U.S. shale plays.

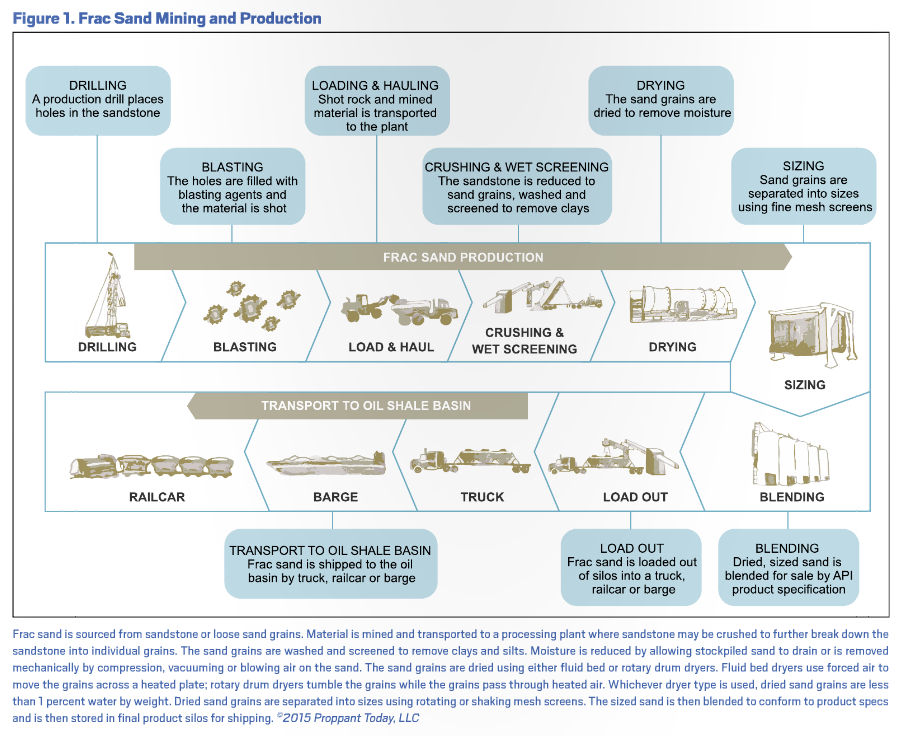

The rise in hydraulic fracturing has driven the demand for frac sand, a natural proppant, from 41 million tons in 2013 to about 54 million tons in 2014. The top five producers in the United States—Unimin, U.S. Silica, Fairmount Santrol, Hi-Crush Proppants and Preferred Sands—produced 55 percent of the frac sand for the industry in 2014. Asphalt producers can give themselves another revenue source by entering the frac sand supply chain, serving as a processing plant to wash, dry, screen and then blend the sand before providing it to the horizontal drilling company/hydraulic fracturing company. There are aspects of preparing frac sand and supplying it that will be familiar to asphalt producers.

Frac sand is subject to quality test protocols recognized by the American Petroleum Institute and the International Organization for Standardization. Particle distribution, grain roundness and sphericity, turbidity, specific gravity, acid solubility, and crush resistance are tested for suitability to withstand temperature and pressure downhole.

Frac sand is sold in graded sizes, much like aggregates. The sand grains are sieved on woven wire mesh screens and blended to meet specs. Products are named by their size relative to the top and bottom mesh numbers, which relates to maximum and minimum grain diameter. Standard product sizes, from coarsest to finest, include 20/40, 30/50, 40/70 and 50/140 also known as “100 mesh.”

One of the differences producers will notice between frac sand and asphalt is that the application for frac sand is in the oil field, most often a distance of 500 miles or more from the production site. As a distribution strategy, leading frac sand producers develop a network of frac sand storage terminals. For example, Fairmount Santrol’s distribution network includes approximately 50 terminals, a fleet of more than 8,500 railcars with the ability to deliver to each of the major basins.

Just as it is in asphalt, plants that are closest to the job site have an advantage. Most frac sand originates from the upper Midwest states and is delivered to Texas, Pennsylvania, North Dakota, and Colorado mainly by rail, but also by truck or barge. In July 2015, Unimin set a record for shipping frac sand by loading and sending a 140-car train to Elmendorf, Texas, according to a July 6 Unimin Energy press release.

Market Moves

Frac sand comprises 92 percent of proppant used with a total market size of about 54 million tons of frac sand sold in 2014. As of the oil pricing environment at press time, frac sand sales volumes were expected to decline by about 15 percent in 2015. Beginning in 2016 and through 2020, market growth is expected to resume as the amount of oil and gas to supply domestic energy increases.

Despite the slump in oil prices at press time, each of the top five frac sand producers had indicated plans to grow in 2015. Given expected demand for proppant, opportunities exist for new entrants. Frac sand requires drying material and moving material, which are core strengths for asphalt producers. On the sales side, asphalt and frac sand customers have little in common. Asphalt producers may want to investigate the potential of partnering with sand miners to dry sand as a way of new market entry.

- This fluid bed dryer manufactured by Heyl & Patterson processes sand for the mining industry. The dryer has no moving parts, and the fluidizing action provides a high rate of heat transfer while handling the sand gently. Photo courtesy Heyl & Patterson.

- Heyl & Patterson, Carnegie, Pennsylvania, manufactures rotary dryers to provide versatility in processing a range of bulk materials. Rotary dryers are forgiving regarding feed material properties such as moisture content and particle size. Photo courtesy Heyl & Patterson.

- In July 2015, Unimin set a record for shipping frac sand by loading and sending a 140-car train to Elmendorf, Texas. Photo © 2015 Proppant Today, LLC.

- Sized sand is blended to conform to product specs and then stored in final product silos for shipping. Photo © 2015 Proppant Today, LLC.

Holly Bellmund is the president of Proppant Today, LLC, a research, media and consulting firm. For more information, contact her at hbellmund@proppanttoday.com or visit www.ProppantToday.com.