Check Out New Asphalt Production Equipment, Services

BY AsphaltPro Staff

As you update the asphalt plant, tank farm, testing lab, crushing site or recycling areas, new equipment is probably on your “to buy” list. Even before we get to CONEXPO-CON/AGG next month, manufacturers and service providers are rolling out new parts and updating existing components to make top quality mixes easier for your crew to produce, load out and track. Check out the most recent offerings from these providers. For example, Systems Equipment provides our in-depth product focus this month with its new ADP-100 blending system, which the company launches this spring.

This screen capture shows the 24-feed capability of Systems Equipment’s updated ADP-100Z.

Blend Big

If a plant has upgraded to multiple feed bins, mineral silos and additive tanks to support a variety of mix designs, the operator may need a robust blending system to assist in production. Systems Equipment has announced a “big production” version of its ADP-100 Asphalt Drum Mix Blend Computer for this purpose. Set to launch this spring, this expanded version of the company’s blend computer is designed to control up to 24 feeder channels for aggregates and additives, including fines, liquids and other materials used to produce drum mix asphalt.

“Many larger plants have determined there is a benefit to having a different feeder for each material used in their many mixes,” said Mitch Duncklee, lead software engineer for Systems Equipment. “The time required to clean out and reload a bin can be saved with this large-scale blend system, and the old saying of ‘time is money’ makes having more aggregate bins very appealing.”

Duncklee added that as recently as 10 years ago, a plant with 14 total feeders would have been considered huge. Today, plants with 16 or more feeders are becoming increasingly common. “Even though the mix formulas don’t use all the feeders at one time, the blend computer needs to have the ability to connect and control all equipment available,” Duncklee said.

The base ADP-100 system on which this large-scale version is built was developed nearly 30 years ago. It was designed to proportion aggregates and additives according to prescribed mix design formulas, and also measures and controls the liquid asphalt mass flow rate so that blends are accurately interlocked to the measured aggregate flow. Besides the 24 feeders, the new I/O will handle 64 discrete inputs and outputs when required. In addition, this expanded system has room for an additional 18 analog inputs for metering various kinds of equipment—including pods, aggregate bins and liquid skids on load cells—as weight depletion feeders.

“From depletion pods, leveling silos, impact flow meters, and even fuel-flow monitoring, the number of different control types in the ADP-100Z is astounding,” Duncklee said.

The ADP-100Z has also been reprogrammed for higher efficiency and better communication, and new packaging was developed for easier connection to the equipment’s wiring. A new layout and cabinet design are suited to the large capacity of this system.

The ADP-100Z uses a graphic display, making data easy to interpret for plant operators. For example, feeders and asphalt tanks can be labeled with the material they contain and mix formulas can be labeled with logical names. Meaningful plant information is displayed in both text and graphic formats.

Using the mouse, the operator can point and click on plant equipment images to directly access detailed operational, calibration and setup data relative to that plant’s equipment.

The ADP-100Z accommodates a trend toward a “glass cockpit” approach to control centers, where computers replace manual push-button controls, gauges and hundreds of feet of wiring. Systems Equipment offers blend, loadout and silo/motor control systems with this clutter-free priority in mind, allowing operators to work more efficiently and safely in their environments.

Systems Equipment is a leading developer and manufacturer of automation and controls for the asphalt and aggregate industries. The product line includes manual controls; blend, loadout and silo/motor control automation; custom-built control centers; metering equipment; and belt scale and feeder components.

For more information, contact Systems Equipment (563) 568-6387

ADM EX Series asphalt plants produce 100 to 425 TPH.

From Asphalt Drum Mixers

Product: EX Series asphalt plant

Launched: 2011

Use the EX Series for quality asphalt production.

Here’s how this component helps you: “Asphalt Drum Mixers’ EX Series asphalt plants produce 100 to 425 tons of material per hour at a low cost per ton. They feature single-drum counterflow technology with separate drying and mixing zones to achieve maximum heat transfer and fuel efficiency. The system is designed to virtually eliminate unsafe hydrocarbon emissions. The compact plants boast long aggregate drying and mixing times, and are capable of processing as much as 50 percent RAP. The EX Series asphalt plants come in portable and stationary models, and can be operated by one plant operator and one loader operator.”

For more information, contact (260) 637-5729 or sales@admasphaltplants.com

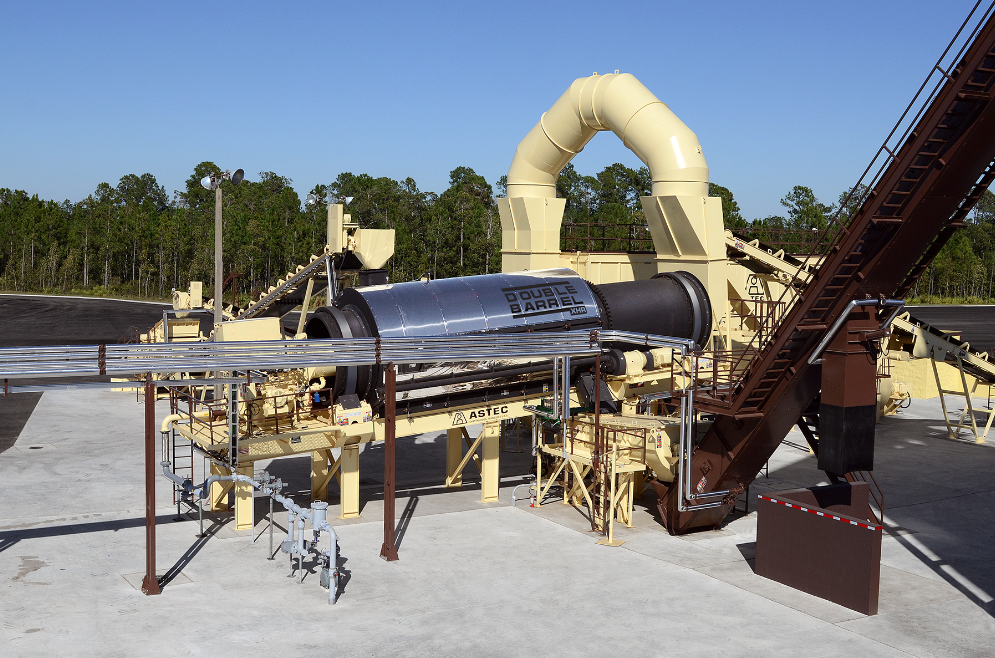

ASTEC Double Barrel XHR

From Astec Industries

Product: Double Barrel XHR High RAP drum dryer/mixer

Launched: 2015

Use this component at the asphalt plant.

Here’s how this component helps you: “Keep operating costs down while making use of stockpiles of reclaimed asphalt pavement. The Double Barrel XHR runs mix with up to 65 percent RAP. ”

For more information, contact Astec Inc. (423) 867-4210, dhunt@astecinc.com

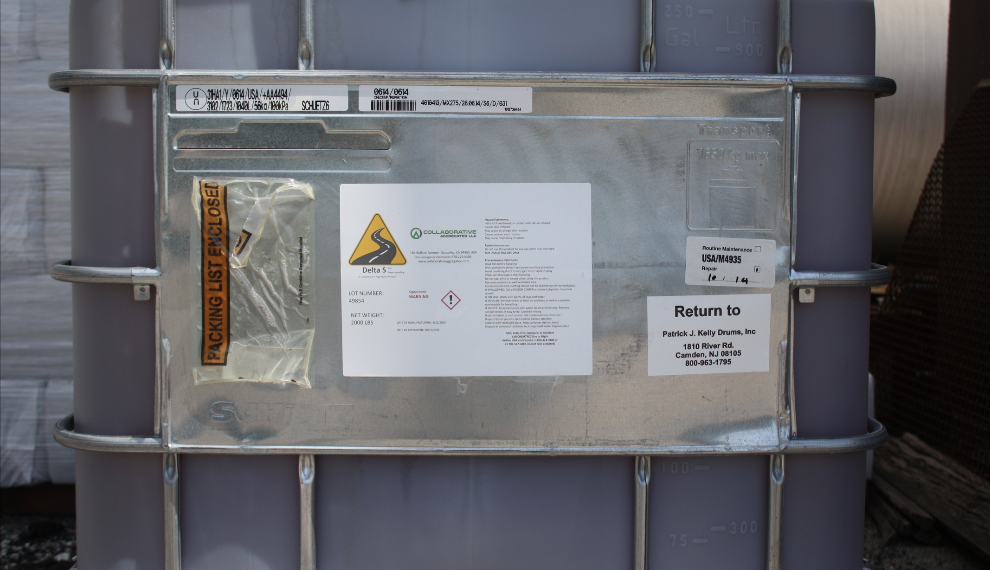

Standard 2,000-pound Net tote of Delta S product

From Collaborative Aggregates

Product: Delta S

Launched: June 2015

Use this engineered chemistry as a liquid asphalt additive at the asphalt mix plant and at the liquid asphalt terminal.

Here’s how this additive helps you: “Delta S is a plant based liquid chemistry product providing for a dual action warm mix asphalt and RAP-RAS recovered binder rejuvenator.”

For more information, contact Jay Bianchini (978) 229-5403, jayb@collagg.com

The Reject Recycle Grinding System from CWMF

From CWMF

Product: Reject Recycle Grinding System

Launched: Spring 2015

Use this system as part of your portable plant setup.

Here’s how this component helps you: “CWMF’s Reject Recycle Grinding System saves your operation money by eliminating waste and minimizing cleanup. It integrates seamlessly between the recycle bins and scale conveyor and can be moved in and out of your portable plant setup quickly and easily. System features include the Tremor ShakerTM, which captures oversized particles and directs them to the grinder, as well as a heavy-duty magnet to prevent metal from entering the drum. According to CWMF customers, the two greatest benefits of this system are smaller product size for better heat transfer and consistent output that reduces belt scale variation.”

For more information, contact Travis Mick (320) 267-3805, travis@cwmfcorp.com

The portable axle load scale from Fairbanks Scales can be set up anywhere you need it.

From Fairbanks Scales

Product: PALS

Launched: December 2016

Use this scale at the asphalt plant.

Here’s how this scale helps you: “Fairbanks Scales Inc., Kansas City, Missouri, provides the portable axle load scale (PALS) to eliminate the need for a pier or slab foundation. It is construction in a subframe, requiring only a flat, unyielding surface to install and complete the unit. This makes it possible to install PALS on concrete or asphalt already in place, saving time and money.”

For more information, contact Ingrid Adel (816) 471-0231 x288, iadel@fairbanks.com

FORTA-FI®

From Forta Corporation

Product: FORTA-FI®

Launched: Over 20 years in the making

Use this additive in the asphalt mix.

Here’s how this additive helps you: “FORTA-FI high tensile strength synthetic fiber for three-dimensional asphalt pavement reinforcement increases pavement durability.”

For more information, contact FORTA Corporation (800) 245-0306, info@fortacorp.com

ADM-100 Automated Dynamic Modulus System from GCTS

From GCTS Testing Systems

Product: ADM-100

Launched: Jan. 22, 2016

Use this equipment in the lab.

Here’s how this equipment helps you: “The GCTS Automated Dynamic Modulus System (ADM-100) can perform the dynamic modulus test on up to six asphalt core samples without requiring any input from an operator. The ADM-100 is completely automatic, with a rotating fixture to move samples into place, an actuator that can determine the required load for testing, and a laser measurement system to determine axial strain. With the ADM-100, an operator does not need to be present to move the samples into position and never needs to open the door of the environmental chamber. By using the automatic systems of the ADM-100, an entire dynamic modulus test on six samples can be performed in two days. This system will dramatically increase the productivity and efficiency of any laboratory while providing extremely accurate results.”

For more information, contact Zachary Phillips (480) 456-0110, sales@gcts.com

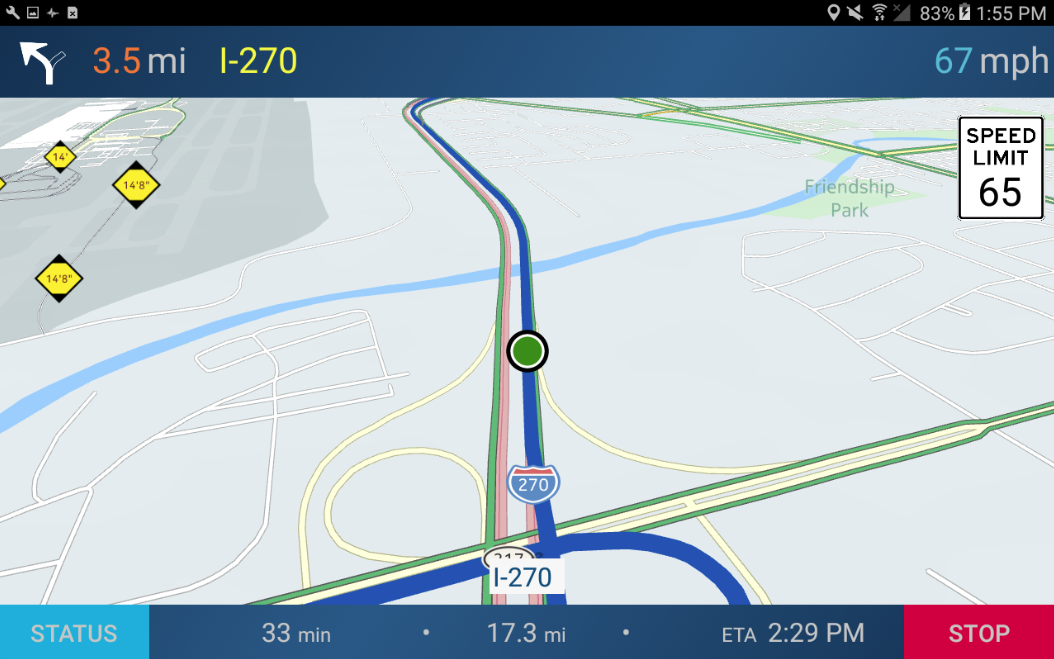

The Keystone On-Delivery mobile app offers truck-specific routing to and from the jobsite based on dimensions and weight of vehicle.

From GivenHansco

Product: Keystone On-Delivery mobile app

Launched: December 2016

Use this in your trucking operations to deliver aggregate or asphalt.

Here’s how this software helps you: GivenHansco, Columbus, Ohio, has successfully field tested the new Keystone On-Delivery mobile app to optimize daily driver operations in asphalt, mining and other material loadout organizations. “Designed by GivenHansco in-house from the ground up, On-Delivery is written for and compatible with most Android devices. Paired with Keystone Dispatch, it delivers the capabilities producers need to schedule and track drivers and trucks on one screen.”

For more information, contact Ron Wallace (614) 310-0060, rwallace@givenhansco.com.

IROCK’s two-deck TS-512 portable tracked screening plant is portable.

From IROCK

Product: TS-512

Launched: 2016

Use this screening plant in the quarry.

Here’s how this screening plant helps you: The TS-512 tracked screening plant from IROCK, Valley View, Ohio, offers sizing and sorting to small- to medium-sized producers. It features two high-energy, two-bearing decks; a 12- by 5-goot top deck and a bottom deck that is 10 feet, 4 inches by 5 feet. It has a 12-cubic-yard hopper and 100-horsepower CAT Tier 3 engine. The three conveyors sort as many as three sizes of product into stockpiles 16 feet, 5 inches high.

For more information, contact (866) 240-0201, sales@irockcrushers.com

A Kenco TCI apron liner set with Tungsten Carbide impregnated into the face as well as the bottom edge

From Kenco Engineering

Product: Kenco Tungsten Carbide Impregnated (TCI) Apron Liners for Horizontal Shaft Impactor (HSI) crushers

Launched: Over 10 years ago

Use this TCI Apron Liner on the bottom row of liners for each apron.

Here’s how this apron liner helps you: “Kenco’s unique Tungsten Carbide Impregnated Apron Liners will last up to four times longer than OEM apron liners. Not only will our apron liner last longer but they also increase crusher efficiency. The desired material size produced by an HSI is determined by the gap between the bottom row of apron liners and the blow bar. By lasting so much longer than the OEM liner, the Kenco TCI liner allows the crusher to maintain its desired gradation much longer. This reduces excessive product return with more “first pass” crushing. This capability is enhanced by Kenco’s ability to impregnated TC into, not only the apron liner face, but also on the bottom edge (as seen in the attached photo). This “L” shaped TCI pattern holds the apron liner edge much longer.”

For more information, contact Kenco Customer Service (800) 363-9859, sales@kencoengineering.com

ProSizer® 3100

From KPI-JCI and Astec Mobile Screens

Product: ProSizer® 3100

Launched: 2007

Use this product to process RAP.

Here’s how this product helps you: “This unit is the ideal mobile solution for milled RAP processing. The compact 31X36 horizontal shaft impactor and double deck high frequency screen make this unit the best investment for asphalt producers. The new swing-out return conveyor allows producers to run closed-circuit or stockpile a third finished product.”

For more information, contact Astec Mobile Screens (815) 626-6374, mail@kpijci.com

From Larson Electronics

Product: HALD-24-1X50LED

Launched: November 2016

Use this light fixture at the mechanic’s shop.

Here’s how this component helps you: “The HALD-24-1X50LED hazardous area LED light fixture from Larson Electronics, Kemp, Texas, is designed to provide operators with a powerful alternative to traditional hazardous location luminaires. The explosion-proof fixture is a 2×2 Class 1 Division 1 explosion proof lay-in LED light panel with a T5 temperature rating. It is for use in hazardous environments where space for lighting is limited. Featuring LED technology and a compact design, this fixture is an upgrade option for replacing existing metal halide lights.”

For more information, contact sales at (214) 616-6180

Pre-swelled and pre-reacted Mix Maxer

From Liberty Tire

Product: Mix Maxer Recycled Tire Rubber

Launched: August 2015

Use this material at the asphalt mix plant.

Here’s how this material helps you: “Mix Maxer provides all of the benefits of recycled tire rubber in an asphalt mix, but is easy to add as a dry powder through the RAP feed system. Mix Maxer eliminates the liquid storage issues associated with rubberized asphalt and can help your customers achieve sustainability goals with a lower cost.”

For more information, contact Doug Carlson (602) 751-6039, dcarlson@libertytire.com

Libra Self-Service Kiosk

From Libra Systems

Product: Self-Service Kiosk

Launched: 2008 (new version introduced in 2016)

Use this Self-Service Kiosk at the at check-in and/or check-out scales.

Here’s how this component helps you: “The Libra Self-Service Kiosks increase revenue by handling more truck traffic without increasing the number of operators. The kiosks increase customer satisfaction by reducing in-yard times, and by allowing the extension of site operating hours. Besides providing clear, concise, configurable instructions to drivers, they can be configured to control external equipment such as traffic lights and gates.”

For more information, contact Ken Cardy (215) 256-1700, kcardy@librasystems.com

Meeker RAP PAK tower and two 30,000-gallon vertical asphalt tanks

From Meeker

Product: Meeker RAP PAK Systems

Launched: 2004

Use this component at your batch plant.

Here’s how this component helps you: “This product greatly increases the amount of RAP a batch plant can process, with systems running up to 40 percent in typical mixes.”

For more information, contact Jeff Meeker ( 717) 667-6000, INFO@MEEKEREQUIPMENT.COM

From Odor Solutions Group

Product: Asphalt Solutions Additive and Roof Odor Solutions Additive

Launched: 1996 and 1998 respectively

Use these patented odor suppressants to neutralize odors during asphalt production and use.

Here’s how these additives help you: “Asphalt Solutions Additive is a patented odor suppressant for paving grade asphalts and heavy oils, such as recycled burner oil. It also comes in a water soluble for tack coat, slurry seals and seal coat. Roof Odor Solutions is another patented additive for use with oxidized roofing asphalts and rubber asphalt applications. When mixed correctly with liquid asphalt cement in the production of hot mix asphalt, our patented additive will neutralize the smells related with production.”

For more information, contact A.J. Ronyak (623) 853-2273

PHCo Lo-Density Unitized Storage Tank Heater, installed into a horizontal tank at an asphalt plant

From Process Heating Company

Product: Unitized Lo-Density® Unitized Storage Tank Heaters

Use this component at the tank farm.

Here’s how this component helps you: “PHCo’s unique drywell-style heaters dissipate controlled heat as low as three watts per square inch on the heater’s sheath to prevent coking or damaging of temperature-sensitive asphalt, oil and emulsion materials—eliminating the need to drain and clean the tank. Because the drywell-style elements are accessible from outside of the tank, they also may be serviced without draining the tank. Since electric heat requires little maintenance, these heaters can reduce downtime even further. And electric heat is environmentally positive because it heats without combustion or emissions and it eliminates a common source of fuel and material spills. With zero emissions, there also are no stacks or expensive permits to maintain.”

For more information, contact Rick Jay (866) 682-1582, rick@processheating.com

An AGG/RAP system consisting of four (4) heaters

From Ray-Tech Infrared

Product: Infrared AGG/RAP Heating System II

Launched: 2016

Use this Infrared Heating System at asphalt plants and aggregate operations.

Here’s how this heating system helps you: “The Ray-Tech Infrared Heating System preheats recycled materials and/or aggregates on their way through the asphalt plant. The number of heaters necessary is dependent on the required TPH, and material temperature. The heaters use a series of stainless steel mixers to increase and mix the surface area while heating. In addition, aggregate and recycled material operations which need to reduce or remove moisture can have Ray-Tech test their materials and determine the number of heaters required for purchase.”

For more information, contact Ray-Tech Infrared Corp (603) 826-3030, jeff@raytechinfrared.com

From Reliable Asphalt Products

Product: Reliable RAP/RAS Systems

Launched: 2001

Here’s how the RAP/RAS system helps you: “Reliable Asphalt Products’ new RAP/RAS Systems combine innovative technology with solid construction to deliver a highly versatile plant component. The Reliable RAP/RAS system allows contractors to maximize both RAP and shingles while maintaining precision weight measurements for both products. Each system can be fully customized to include one to three RAP bins as well as up to two load cell-equipped RAS bins.”

For more information, contact the office (502) 647-1782

This is Stockpile Reports’ inventory management screen, the iPhone App for ground-based measurements, and a DJI Phantom 4 Pro for aerial-based measurements.

From Stockpile Reports

Product: Inventory Management System

Launched: 2012

Use this product to perform and manage your inventory measurements, reviews, approvals and submissions to finance/audit.

Here’s how this component helps you: “The Inventory Management System from Stockpile Reports enables you to perform quick, accurate inventory at scale via drones, planes or iPhones, and reduce cost overruns and stockouts.”

For more information, contact Maury Margol (425) 285-4303, maury.margol@stockpilereports.com