CEI’s AR Blending Plant Update

BY AsphaltPro Staff

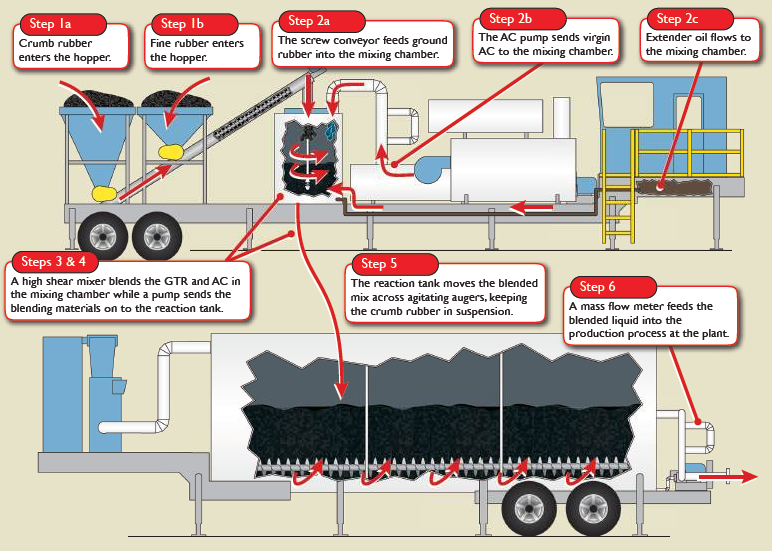

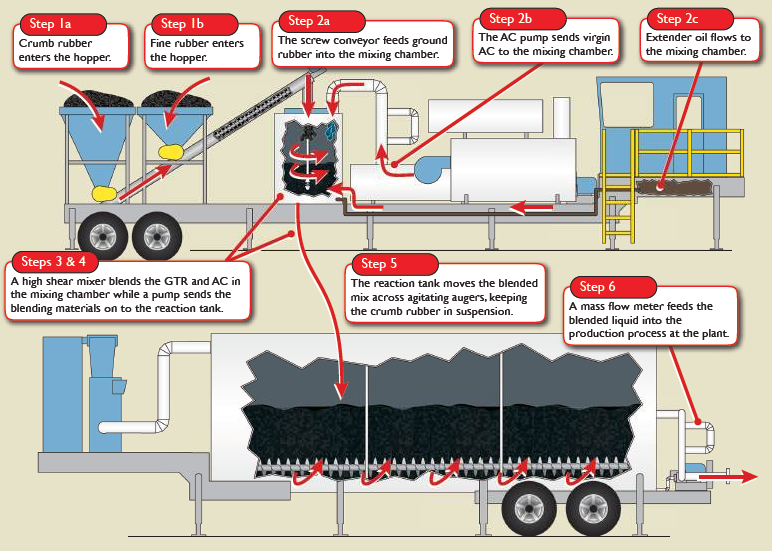

With its increasing popularity, ground tire rubber (GTR) use has tight specs for use in California. Researchers in that state have determined that, by mixing high natural rubber content from finely-ground truck and aircraft tires with standard crumb rubber from ground car tires, and adding an extender oil, the resulting binder is resistant to reflective cracking. Whether using a blending plant in that state or elsewhere in the Union to supply asphalt-rubber binder, CEI Enterprises, Albuquerque, offers portable asphalt-rubber blending plants with the mixing unit and reaction/storage tank ready to take on the different crumb rubber gradations. Here’s how they work.

First, the producer feeds both the fine, high natural rubber content material, and the standard crumb rubber into their respective hoppers. The air canon in each hopper is designed to keep the material flowing freely to the screw conveyor, which controls the volume going to the mixing chamber. Load cells measure the material by weight.

At the same time, an asphalt cement (AC) pump with a variable frequency drive sends virgin AC to the mixing chamber. A metered amount of extender oil is also pumped into the mixing chamber to enhance the blending of the two types of rubber. A high shear mixer running at a speed of 3,400 rpm homogenizes the ground rubber particles with the liquid asphalt.

As the materials are mixed, a pump sends the blending materials to a reaction tank. During the mixing process, fresh GTR, virgin AC and extender oil continue to flow into the chamber.

The compartmentalized reaction tank moves the blended mix across agitating augers mounted horizontally so that 1) the crumb rubber remains in suspension, 2) new mix enters the tank at one end and 3) aged mix exits the tank at the other end. Vent condensers handle external cooling and Smog Hogs control final blue smoke.

A mass flow meter measures supply from the reaction tank to the plant for delivery of GTR-modified AC. <endmark>

For more information, contact CEI at (800) 545-4034 or visit www.ceienterprises.com.