CEI and Fireye’s Nexus 4000 System

BY AsphaltPro Staff

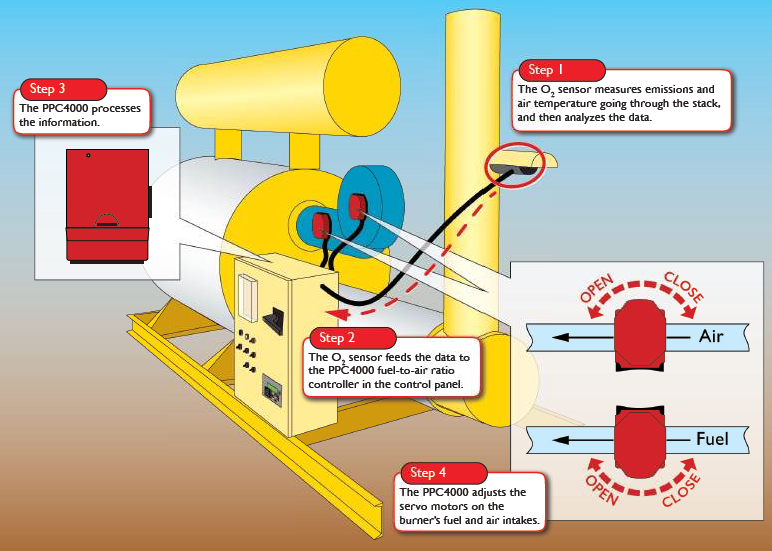

To offset the effects of air temperature shifts on burner emissions and cool-weather burner performance, the engineers at Fireye™ developed the Nexus 4000 system, which is available through CEI Enterprises, Albuquerque, N.M. Here’s how it works.

To offset the effects of air temperature shifts on burner emissions and cool-weather burner performance, the engineers at Fireye™ developed the Nexus 4000 system, which is available through CEI Enterprises, Albuquerque, N.M. Here’s how it works.

Combustion efficiency is affected by changes in air temperature, even if the burner is properly tuned. As air temperature increases and air becomes less dense, the burner’s fuel-to-air ratio increases, which causes the burner to run rich. This results in wasted fuel and higher emissions. Conversely, a drastic decrease in air temperature can cause the air to become dense enough that it starves the burner of adequate fuel, causing unwanted burner shutoffs.

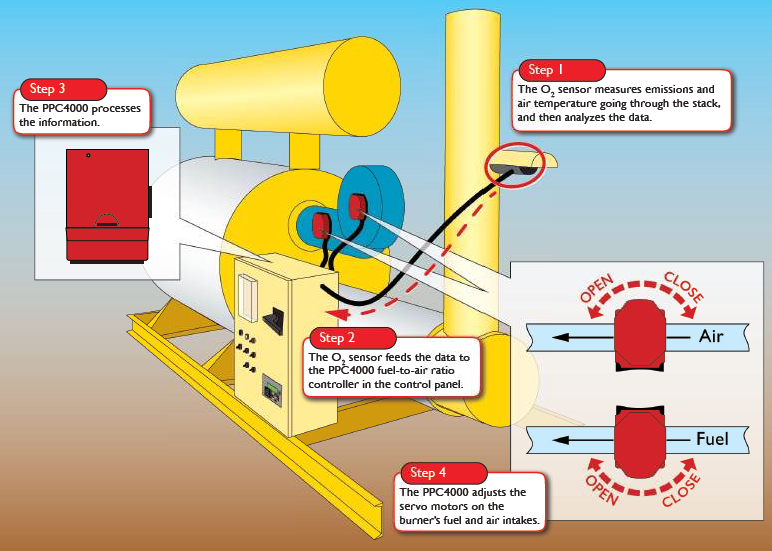

First, the Nexus 4000 management system’s O2 sensor, which is installed directly in the heater’s stack, measures emissions and temperature data. The sensor analyzes the exhaust going through the stack and feeds that data to the PPC4000 fuel-to-air ratio controller, mounted in the heater’s control panel.

The PPC4000 processes that information in real-time and automatically adjusts the burner’s fuel-to-air ratio by continually adjusting servo motors mounted on the burner’s fuel and air intakes. As less fuel, or more air, is needed for proper combustion efficiency, these adjustments are performed continually by the servo motors.

User interface is provided by the NXD410 keypad display, and flame safeguard control is provided by the YB110. Both of these are mounted in the heater’s control panel. <endmark>

For more information, contact CEI’s Parts & Service Dept at (800) 545-4034.