August Product Gallery

BY AsphaltPro Staff

What’s New in Asphalt Production?

AsphaltPro sets the standard for equipment and service information by focusing on what’s new in the industry. There are companies in the asphalt industry with R&D departments that have crafted remarkable components for aggregate and asphalt production that stand the test of time. Over the years, those components require mere tweaking here and there to bring them up to date with some new code or concept from EPA. As those modifications are introduced, AsphaltPro is honored to share the information with readers, keeping everyone abreast of changes in our industry.

Take the 12-foot Whirlwind air classifier from Sturtevant that was installed at Rockydale Quarries in Roanoke, Virginia, in 1961. The classifier is still making agricultural lime and minus ¼-inch sand for asphalt production after Sturtevant supplied parts to Rockydale to do some refurbishing. Writer Carl Emigh shares the whole story here:

The machine was refurbished by Rockydale with parts supplied by Sturtevant in 2015 after more than 53 years of continuous operation. The refurbishing cost was 40 percent of the cost of a completely new machine.

“We worked closely with Sturtevant throughout the refurbishing process,” Rockydale Vice President of Operations Gary Hubbard said. “They tailored everything to our needs. I just gave them the requirements we needed to work within, and they handled it with us from there.

“Sturtevant was able to refurbish the air classifier since the basic design hadn’t changed much,” Hubbard continued. “Essential parts such as the fans, distributors and cones were original. And all Whirlwind parts are readily replaceable, which eased the refurbishing process. Most of the original rotating parts did not need to be replaced, including the heavy-duty drive mechanism.

The Sturtevant 12-foot Whirlwind air classifier was installed in 1961 and refurbished to like-new condition in 2015. It makes aglime and asphalt sand.

“Two key Sturtevant people on the project were Senior Project Manager for Air Classifiers Joe Muscolino and Parts Manager Rick Fortini. Both have been with Sturtevant for more than 30 years. They worked in concert with our Luis Lopez to make it all go like clockwork.

“Rockydale is a small, family owned company,” Hubbard continued. “So is Sturtevant. That’s one of the reasons we like working with them. They’ll go the extra mile to accommodate your needs and give you the attention you won’t always find with larger companies. We got a like-new 12-foot Whirlwind classifier brought back to its original condition in minimum time and at a good, low cost.”

Rockydale also uses a 16-foot Sturtevant Whirlwind air classifier to produce aglime and minus 5 mesh sand for concrete production. That machine was installed in 1985 and replaced in 2007 by another 16-foot Whirlwind when it was damaged by fire.

“Our crushing and screening system uses a 42-48 jaw crusher, four cone crushers and seven screens to produce rip-rap, gabion, 3-inch by 1-inch, 57s, 8s, and 10s,” Hubbard said. “We use the Sturtevant air classifiers exclusively to produce agricultural lime and the concrete and asphalt products. One circuit produces 70 TPH; the other produces 50 TPH. The classifiers have no trouble keeping up with that production rate.

“The feed material is dolomitic limestone with 4 percent silica and no caustic chemicals, which keeps wear to a minimum,” Hubbard said. “Acceptable moisture content averages 2 to 5 percent. Anything higher slows production. The two air classifiers are fed a fine graded material and produce a very high quality sand. To aid in moisture control, the 12-foot is enclosed and the 16-foot has a covered feed conveyor.”

Hubbard says the Sturtevant Whirlwinds are tough, efficient, and simple to operate and maintain. “We do a weekly inspection: just open up the door to see how the blades, tips and distributor plate look. There’s virtually never a problem so we close up and keep on producing. Once the selector blades are dialed in to match the gradation you want, the upkeep on the unit is very simple. Nevertheless, diligence in maintenance and service are still crucial. Ray St. Clair, who has been with Rockydale for 39 years, has been a major contributor to the ‘care and handling’ of our air classifiers. We keep all our equipment in good repair, and it pays off in production efficiency and long service life at minimum cost. Our Sturtevant Whirlwinds are the prime example.”

Rockydale Quarries Corporation has operated in the Roanoke Valley since 1932 and now has eight plant locations across the state of Virginia, providing a wide variety of aggregates, lime, and topsoil for construction, agricultural, and residential markets.

We’re taking a wide look at plant and quarry equipment this month. Many OEMs with R&D departments revamp complete systems, software, iron and parts to make completely new products to address different needs in the aggregate and asphalt production realm. It takes guts to put in the time, money and manpower to fabricate a new WMA injection system, a new material delivery system atop the silos, a new burner, and the list goes on. When a manufacturer launches a new product or custom-builds a component, again AsphaltPro is proud to share that news with readers, keeping everyone up to date with the advancements in our industry.

This product gallery focuses specifically on the branch of our industry that influences your bottom line when it comes to the production of aggregates, asphalts and mixes. This month, we asked OEMs and others in the industry to provide information related to mix production for equipment and services they launched this year. You’ve seen the old stuff. In alphabetical order, let’s take a look at what’s new in the asphalt production market place to enhance your bottom line.

From Atlas Copco Secoroc

The new Atlas Copco Secoroc Powerbit series offers top hammer surface drilling with the company’s trapezoid-shaped buttons—Trubbnos—and increased service life.

Powerbit is the all-new range of top hammer bits for surface drilling from Atlas Copco Mining and Rock Excavation LLC, Commerce City, Colo. The series is designed for increased performance in hard to soft, abrasive to non-abrasive rock with the patented Enduro Extra surface treatment to give the bit more strength. Engineers have combined all aspects of drill-bit technology for long service life. The range features an entirely new bit shape with a harder, stronger steel bit body. Previously incorporated semi-ballistic buttons have been replaced with Atlas Copco Secoroc’s unique, trapezoid-shaped buttons—Trubbnos.

Results of 20 test series conducted at 13 sites globally, drilling more than 164,000 feet, in a variety of rock conditions, demonstrated increases in service of 20 percent or more than the market’s leading competitor bits with penetration rate increases of up to 10 percent. Product Manager of Atlas Copco Top Hammer Rock Drilling Tools Ross Gjerde said: “Our power bit testing domestically and abroad has consistently demonstrated substantial improvements in bit life when compared to our old assortment, and competitive product.”

- Use this in the quarry.

- For more information, contact Sofie Gielen at (720) 235-2325 or gielen@us.atlascopco.com

From CEI Enterprises

CEI Enterprises has added a second line of hot oil heaters, the CEI helical coil heater pictured on the right.

In addition to its well-known and established line of jacketed firebox hot oil heaters, CEI of Albuquerque, New Mexico, now also offers a new line of helical coil heaters. Standard helical coil modules feature two-pass design in outputs ranging from 1.2 million to 4 million BTU/hour. Larger sizes, as well as three-pass designs and vertical models are also available.

The helical coils are designed and built to ASME code. They are designed to provide a large heat transfer surface area, low flux rates, and an idea fluid velocity of 7 to 11 feet per second. ASME stamp is available as an option.

Both lines of CEI hot oil heaters feature UL-rated, NEMA 4 control panels as standard equipment. These panels provide watertight protection against splashing water, hose-directed water, rain, sleet, snow, ice, dirt and windblown dust. Panels that meet CSA specifications, and other NEMA standard enclosures are available optionally.

An extensive number of options for enhanced fuel efficiency and multiple thermal oil circuits are available for both lines of CEI hot oil heaters.

- Use this at the tank farm.

- For additional information, contact CEI at (800) 545-4034.

From CWMF Corp

The tandem bin set-up of the Portable Longneck Recycle System from CWMF directly feeds RAP into the recycle collar of the drum.

The Portable Longneck Recycle System from CWMF Corp originally rolled out in 2009, but it’s been updated in 2016 with a custom, two-bin set-up headed to a client in June. The portable longneck recycle system directly feeds RAP into the recycle collar of the drum. It is available in single-bin set-up or a tandem bin set-up. A standard system would include a scalping screen and scale conveyor. It consolidates the typical recycle bin and scale conveyor set-up into one chassis. In addition, CWMF is able to incorporate a hammer mill system that will grind the oversized product coming off the screen. Quicker plant tear-down, quick set-up and less transportable loads are part of the design.

- Use this for RAP mixes.

- For more information, contact Travis Mick at (320) 267-3805 or travis@cwmfcorp.com.

From D&H Equipment

D&H Equipment, Blanco, Texas, released its Heat Guardian heater and tank monitoring solution at the end of June 2016.

D&H Equipment, Blanco, Texas, released its Heat Guardian tank and heater monitoring solution to the marketplace at the end of June. It was designed for owners, managers and operators to remotely monitor their hot oil heating systems and tanks. It provides real-time data to the user by text, web-based monitoring, as well as the full color touchscreen panel display, and includes the capability to send configurable text alerts based on user input variables.

Each Heat Guardian monitors events including power loss, a hot oil heater’s flame fault and oil temperature, and up to three tanks’ temperatures and levels. Receiving an alarm or getting the current system status is as easy as sending a text, according to the manufacturer. A built-in battery backup will allow the unit to alarm you even in the event of total power loss at the plant.

Features of the Heat Guardian include:

- Instant text notification to two numbers for power loss, heater flame failure or faults, high and low level alarms for tanks, and high and low temperature alarms for heater and tanks;

- Operations monitoring via text, web browser or Heat Guardian’s touchscreen panel;

- Interfaces with existing RTDs, thermocouples and analog inputs without having to replace installed sensors;

- Adjustable alarm setpoints for levels and temperatures; and

- Ability to reset burner via text.

- Use this to monitor your tank farm.

- For more information, contact Jason Cox at (830) 833-5366 or sales@dhequip.com.

From Dexter+Chaney

When heavy highway and civil contractor Evans & Associates Enterprises Inc., Ponca City, Oklahoma, learned the construction software it had relied on daily since the mid-1990s would no longer be supported, the company knew the replacement challenge also presented an opportunity to improve its operations.

“We wanted the functionality to bring a lot of the consistency into our operations and into our back offices,” Lee Evans said. He’s the president and CEO of Evans & Associates. “We wanted to streamline a lot of the processes that were not tied together well before—from our operations in the field to our accounting to our compliance. When we looked at Spectrum, we knew we could do just that.”

The company began in 1960 when Evans’ father and a partner purchased a single asphalt operation in Ponca City.

Evans & Associates has steadily grown over the years. The company began in 1960 when Evans’ father and a partner purchased a single asphalt operation in Ponca City. Fifty-six years later, the company has grown and diversified to 17 independent business units throughout Oklahoma, employing more than 300 people. While the Company continues to provide hot mix asphalt and construction services to its customers in North Central Oklahoma, the company also manufactures ready mixed concrete, quarries sand and aggregates, installs underground utilities, and markets Type “C” fly ash. With operations located in Ponca City, Red Rock, Alva, Enid, Perry, Bartlesville, Miami, Grove, Skiatook, Altus, Lawton, Ft. Sill, Snyder and Oklahoma City, Evans & Associates continues the proud tradition of its founder with a reputation for quality and integrity.

“Evans & Associates has shown over the years that it is committed to smart growth and building strong relationships with its clients and we’re very happy to welcome them as a client of ours,” Dexter + Chaney President and CEO Norbert Orth said. “We look forward to helping Evans & Associates streamline their operations and take their business to the next level.”

Evans said when his company learned that its Maxwell Systems’ StreetSmarts software would no longer be supported, it was important to keep their operations smoothly running during a software transition. In demos with Dexter + Chaney and its business partner, OnPoint Construction Software, Evans and his team were able to see how Spectrum worked with live data and were especially impressed by the software’s navigation and its Document Imaging and Plan Room functionality.

“Spectrum’s Plan Room functionality was huge for us,” Evans said. “We have a big heavy civil group that does a lot of work on military bases and after looking at the functionality in Plan Room, we feel it will be quite helpful for that group in providing real-time collaboration with the multiple subcontractors on those types of projects.”

Evans added that Dexter + Chaney sales engineers listened to, and put the needs of Evans & Associates first during demos, including working with the company to fit the software to meet those needs. “It was a pretty unanimous decision for everyone on our team; once we looked at all of our options on the market, Dexter + Chaney’s Spectrum product stood out.”

One of the most impressive features for Evans though, was not necessarily software related.

“The thing that really stood out to me was Dexter + Chaney’s approach to customer service,” Evans said. “It’s hands-on. You’re talking to a person rather than a help desk where you send an email and wait for a reply. We’re old school and like talking to people. When we do have an issue or something we want to talk through, we like the fact that we can pick up the phone and get it resolved quickly.”

- Use this to manage product.

- For more information, contact (800) 875-1400 or info@dexterchaney.com.

From Eagle Crusher Company

Eagle Crusher Company’s latest product innovation is the UltraTraxx™ portable impactor, equipped with the company’s UltraMax® UM-15 impactor.

UltraTraxx™, Eagle Crusher Company’s latest product innovation, came on the market May 2016. This portable impactor track unit, equipped with the company’s UltraMax® UM-15 impactor, is designed for ultra-mobile crushing on the job site.

To keep producers up and crushing, UltraTraxx has fuel capacity for more than 10 hours of operation. The UM-15 impactor provides the industry’s only lifetime rotor warranty (North America only) on its solid-steel, three-bar, sculptured rotor for minimum downtown. The load-sensing hydraulics improve fuel efficiency and reduce component wear for lower operating costs and minimum downtime as well, according to the manufacturer.

Helping producers achieve their highest production rates, the UltraTraxx all-hydraulic, hydrostatic-drive system allows independent operation of the conveyors, feeders and impactor. Material processing efficiency is maximized by the UltraTraxx smart feeder drive system by monitoring engine load for more efficient production and product consistency.

Further enhancing production rates, the UltraTraxx dual-motor, under-crusher pan feeder, with discharge clearance of more than 20 inches, provides greater material flow and maximizes uptime by virtually eliminating clogging, according to the manufacturer.

UltraTraxx high torque drives ensure superior tramming and gradability, enabling the unit to track while crushing, so operators can continue stockpiling and also maximize production. Uptime is maximized with the UltraTraxx on board hydraulic cooling fan that reverses to minimize heat exchanger clogs.

Thoughtfully designed maintenance features also help provide maximum uptime and include the easily removable discharge conveyor for quick access to the under-crusher area for inspection, maintenance, and cleaning. With the discharge conveyor removed, operators can also quickly inspect and maintain the conveyor. The discharge conveyor is fitted with one of the plant’s easy-access grease banks for lubricating the head and tail pulley bearings, and the conveyor folds for transport or to remain out of the way for more compact storage when not in use.

To help ensure the highest quality spec product, UltraTraxx is equipped with a permanent, cross-belt magnet to remove steel contaminants from crushed material. The magnet is reversible to allow steel to discharge from either side of the unit, and the magnet does not need to be removed for transport.

The UltraTraxx heavy-duty hopper is sized for feeding with a loader or excavator, and the unit has a discharge conveyor height of 12 feet 5 inches for feeding directly into an optional screener.

The UltraTraxx includes a wireless remote control to operate and monitor plant functions including filter status, hydraulic oil temperature, engine load and charge pump pressure. The control can be tethered to the unit for operation if the remote battery loses its charge. Typically, a charge will last 8 to 10 hours, or operators may change the battery when filling the fuel tank. Remote monitoring of crusher production performance, engine loading, temperature, and location is also available. These may be monitored via wireless service to a smart phone or computer.

- Use this to crush material.

- For more information, contact Eagle at (800) 253-2453 or sales@eaglecrusher.com.

From Fairbanks Scales

Talon scales from Fairbanks now come standard with Intalogix® digital load cell technology for a strong digital interface.

Fairbanks Scales Inc., Kansas City, Mo., now offers its Talon series highway vehicle scales with Intalogix® technology. The Talon is offered in two capacities to meet unique application requirements. The Talon HV design is dependable for most applications, according to the manufacturer. The Talon HVX is designed to withstand duty-cycles of extreme volume weighing applications.

The Talon is offered with either a steel deck or field-poured concrete—built to federal bridge standards. Talon scales have a solid deck design to resist deflection and metal fatigue. The open bottom design creates a natural ventilation system. Armored stainless steel load cell cabling is provided for durability. The Talon also has hermetically sealed load cells for protection from moisture as well as encapsulated circuit boards.

Fairbanks’ innovative Intalogix digital load cell technology is a standard feature of all Talon scales now. Intalogix works by converting a weak analog load cell signal to a stronger digital interface. Intalogix technology is designed to ensure consistent performance.

The Talon product line is available for application in permanent above-ground foundations or shallow pit applications.

- Use this at loadout.

- For more information, contact Fairbanks at (800) 451-4107 or visit fairbanks.com.

From Heatec

The Recon™ monitor system from Heatec was introduced in late 2015.

Heatec says that managers of asphalt facilities in the United States and Canada are showing a remarkable response to the Recon™ monitor system that the company introduced in late 2015. Recon units are now in operation at 23 facilities and being installed at 9 others. Heatec is working through a significant backlog of orders for additional units at press time.

The Recon system enables plant personnel to remotely monitor the live status of asphalt heaters and asphalt storage tanks at their HMA plants. Operators use this information to avoid unwanted shutdowns due to heating problems. And they keep close watch on asphalt use and inventories to better plan tank refills.

The Recon monitor shows heater alarm status, hot oil temperatures, asphalt tank temperatures, tank liquid levels and tank mixer on-off state. Operators can use a smartphone, tablet or PC to access the system.

Chris Cook, Plant Superintendent at King Asphalt, Pacolet, South Carolina, says he really likes the remote access that his Recon system provides. He uses his iPhone to keep close watch on tank levels and temperatures at their facility. And he looks forward to finding ways to use the historical data that the system records.

- Use this at the tank farm.

- For more information, contact Heatec at (423) 821-5200.

From Larson Electronics

The EPL-48-2L-LED-D fixture carries a T6 temperature rating and is approved for Class 1 Division 1 Groups C and D, Class 1 Division 2 Groups A, B, C and D environments where flammable or combustible gases, vapors, dusts, fibers, and flying exist or may potentially exist.

When it’s time to repair or paint a component at the plant, the team from Larson Electronics, Kemp, Texas, has that work space lit up for you with the new industrial LED fixture that is rated as explosion-proof. The EPL-48-2L-LED-D is equipped with two dimmable LEDT-series bulbs that produce 2,875 lumens per bulb. The dimmable 23-watt LED lamps produce 125 lumens per watt and offer a low amp draw. They work with standard 0-10 dimming controllers and have been tested on Lutron and Leviton electronic dimmers. The LED assembly is mounted within a tube constructed from extruded aluminum and a polycarbonate lens. This unit is voltage-specific and operates on 120 volts AC or 277 volts AC. The fixtures are standard surface mounted via two swivel brackets; each bracket is cinched to the bracket mounting peg on each side of the light. Larson CEO Rob Bresnahan said: “This popular fixture is equipped with our specially designed 23-watt dimmable LED lamps, providing operators with the ability to adjust the intensity of the light in a work area. When using an electronic dimmer switch, the LED lamps will dim from 0 percent up to 100 percent by a user-provided switch.”

- Use this in your work area.

- For more information, contact Larson at (800) 369-6671 or larsonelectronics.com.

From Phoenix

Phoenix of Hamburg, Germany, introduced a virtual catalog June 23 for its heavyweight conveyor belts, giving end users and distributors an online option for efficient ordering. “The new secure website is designed primarily as a sales tool for distributors,” Bret Hall said. He’s the head of Phoenix and NBS-Service-NAFTA. “It will give the user the option of customizing products and services, all online and all instantaneously, and enhance the ordering process.”

The virtual catalog includes everything that the 109-page hard copy catalog provided, including belt construction and cover compounds, above-ground and below-ground application recommendations, and specific data on steel belts and pipe belts. “We also are including other information pertinent to selling conveyor belting such as service tools, belt selection as well as research data,” Hall said.

- Use this for material conveyance.

- For more information, see the catalog at http://www.phoenixcbgvc.com.

From Powerscreen

The Premiertrak 600 Pre-Screen from Powerscreen was also on display at Hillhead. The diesel-hydraulic and diesel-electric variants of the Premiertrak 600 jaw crusher have been designed for maximum production with increased uptime and low running costs. A vibrating grizzly feeder feeds the high capacity jaw with variable speed control and a large grizzly area. The bypass chute is also fitted with wear-resistant liners as standard, and incorporates an adjustable five-position deflector plate to divert material to either the product or side conveyors.

Celebrating 50 years in business this year, Powerscreen launched celebrations at the Hillhead Exhibition June 28 through 30 in Buxton, England, showcasing existing and new products with live demos. One of the newly released products from the company is the Trakpactor 550 horizontal impact crusher for the mid-to-large range class. It has been designed to promote an easy and effective flow of material to minimize any potential material build-up and thereby ensure maximum uptime. The 2.1-meter pre-screen length and large open area allows the maximum amount of fines to be removed. The brand new chamber design has been rigorously developed and tested for confidence in its durability. Optional features such as the hydraulic inlet lid and the automatic adjustment system ensure ease of use for the operator, whilst the auto rotation system for blow bar changes also demonstrates the focus on machine safety. Like all Powerscreen crushers, the Trakpactor 550 comes complete with the Pulse remote monitoring system as standard. Powerscreen Pulse is a remote monitoring, fleet management system allowing crushing and screening equipment operators and owners to have unrivalled access to key data. Analysing this data can improve machine operation, increase uptime and allow in-depth reporting and fleet management.

- Use this to crush virgin aggregate.

- For more information, contact customer support on www.powerscreen.com.

From Rotochopper

To help customers capitalize on growing opportunities in recycling markets, Rotochopper is launching a new line of industrial slow-speed shredders. The track-mounted diesel TS-2 made its debut at Expo Richmond in Richmond, Virginia. The TS-2 is an aggressive dual-shaft shredder designed to pre-process stumps, commingled C&D, railroad ties, and other forms of mixed or contaminated waste.

Vince Hundt, Rotochopper co-founder and international sales manager, said, “The introduction of the TS-2 is the completion of a long-term Rotochopper plan and fulfills the promise to provide our customers with a complete line of grinders, from high-torque to hammermill.”

The TS-2 shredder minimizes the costs of turning challenging feedstocks into end products like compost, landscape mulch, and boiler fuel. By reducing maintenance costs and increasing total uptime percentage, the TS-2 shredder maximizes the value of raw materials.

Boasting simplified operation, streamlined maintenance and rugged reliability, the TS-2 features an open shredding table, allowing dirt, stones and other abrasives to pass. Paired with easily accessible routine maintenance areas, the TS-2 avoids the complicated upkeep often associated with slow speed shredders.

Like every machine in the Rotochopper line-up, the TS-2 is backed by Rotochopper’s factory-direct customer support, with service technicians who work exclusively on Rotochopper equipment. “Our unprecedented customer loyalty will continue to grow because of our over-the-top service,” Hundt stated. “We have a reputation to honor; we love our customers, and we won’t let them down!”

- Use this for recycling.

- For more information, contact Monte Hight at (320) 548-3586.

From Stansteel/Hotmix Parts

The Accu-Add™ from Stansteel is designed to let producers smoothly add different liquids to a mix.

Hotmix Parts & Service®/Stansteel® introduces the Accu-Add™. Designed, built and installed for use with 18 different types of liquids including rejuvenators, anti-strips, Evotherm™, polymers, latexes and more. The applications include delivery of the liquid, proper metering, interlocking and calibrating, for achieving the goal of better and more cost-effective mixes. The Accu-Add is designed for use with any RAP or RAS process.

- Use this for blending mixes.

- For more information, contact Chris Loher at (502) 245-1977.

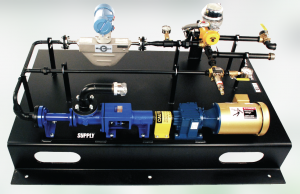

From Systems Equipment

This screen capture example shows the 1292 Material Temperature Capture at Time of Load, the newest companion product to System Equipment’s loadout system, the WIN-LC3000.

SYSTEMS Equipment has announced the release of the 1292 Material Temperature Capture at Time of Load, the newest companion product to the company’s Windows-based loadout system, the WIN-LC3000. Product conception was spurred by feedback from both producers and end-users in the asphalt industry with a common objective—to have an efficient way of measuring and documenting the temperature quality of hot mix being used for any given job.

The 1292 assembly consists of a PLC and two modules to be mounted in the control center (with an optional enclosure), as well as a probe and housing assembly that is mounted to each loadout silo (or drum, if used with the blend system).

Asphalt plants employing this technology have the unique position of being able to measure and document asphalt temperatures at time of load, as well as adjust temperatures with better precision for ongoing production based on feedback from pavers applying the product. This quality assurance discipline provides accountability throughout the asphalt “chain” for any given job. Some state- and federally-funded projects also require this temperature measurement to ensure that the asphalt mix meets code-specific requirements.

The 1292 includes a single infrared probe protected by an enclosure measuring approximately 4.5 inches high by 3 inches wide by 3 inches deep. One probe per silo is required. When used in tandem with the loadout system, the active end of the probe is mounted to the loadout silo frame and directed toward the truck bed. A small air valve incorporated into the enclosure prevents debris from attaching itself to the end of the probe and skewing the reading. As loading proceeds, the probe measures the temperature of the newly loaded asphalt mix. The temperature reading is both stored in the loadout database and printed on the driver’s loadout ticket.

The 1292 assembly can also work cooperatively with the blend system, capturing material temperature as the asphalt mix exits the drum. Due to the thick metal housing on traditional temperature measurement units, getting an accurate reading takes time as the heat must work its way through the housing and to the probe. “With the 1292 assembly, the reading is almost instantaneous,” Fred Axmear, software engineer at SYSTEMS Equipment Corporation, said. “This is particularly helpful with small batches, and also improves reaction time when temperatures need to be adjusted because feedback is both quick and accurate.”

He added, “By installing the 1292, operators now have a much greater level of control over the quality of their hot mix. Having the ability to document mix temperatures at time of load also gives them an added level of assurance and documentation for jobs with higher requirement levels, such as federal highway projects. Their bases are covered.”

- Use this at loadout.

- For more information, contact Systems Equipment at (563) 568-6387 or email info@systemsequipment.com.

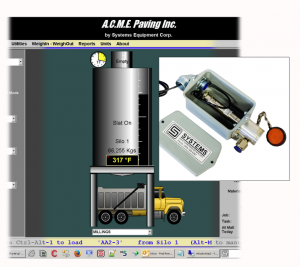

Updated from Systems Equipment

The Total System Control, launched by SYSTEMS Equipment Corporation in early 2014, is among the most evolutionary products in SYSTEMS’ line of asphalt plant automation, boasting frequent updates and features designed to make life easier for plant operators. Offering touch-screen control of all motors and/or silos, the TSC makes “total control” possible from one to two monitors in a single station within the control room.

“Gone are the days of hard-wired panels with gauges and push-button controls,” Mitch Duncklee, software engineer and developer for SYSTEMS Equipment, said. “Work spaces are now clutter-free and highly efficient.”

Duncklee added that SYSTEMS’ TSC is not rigid when it comes to making plant changes. It is customer programmable because it is “English-language driven,” Duncklee said. “Those who are not versed in complex PLC programing jargon can still understand the software.” To add, move or modify a button can be done by in-house technicians. No Internet connection is typically required.

The TSC lists many features, including recent updates that have made it more intuitive, easier to program for first-time users, and that reduce, if not eliminate, the need for costly service trips for simple changes. Among most recent user-friendly enhancements, the TSC makes:

- adding a new operator or changing an existing one even simpler.

- maneuvering menus easier by making options more visually obvious and simple to find.

- customization possible with “run mode” adjustments for multiple operators.

- reconfiguration of motors or silos simple, as plant technicians can easily add, delete or relocate displayed ‘buttons’ to match plant changes.

“The TSC has made modifying something at the plant as easy as changing a mix formula,” Duncklee said. “The only expense is if more hardware needs to be added.”

New “operators” on the TSC include handling of valves (or flop gates) and limits, multiple interlocked inputs for alarms or indicators, and a tank operator that monitors and controls the functions of each tank.

“Think of programming the flop gate logic for the top of the silos in plain English, without running cables between the limits, in the comfort of the control center,” Duncklee said. “It is easy to set up a combination of existing inputs to fire an output or sound an alarm, all without touching PLC ladder code.”

Rick Moulton of Construction Resources Management compares SYSTEMS’ TSC to a “glass cockpit,” referring to the replacement of dials, gauges and buttons with LCD monitors and touchscreens. “We’ve been upgrading our plants with SYSTEMS’ TSC to achieve the same results,” he said. “We can now configure and arrange buttons and indicators to allow our operators to better run the plant in a much less cluttered environment,” Moulton said. “And like pilots, our operators can now ‘fly’ their plants more efficiently, not having to move all over the control center to do their work.”

- Use this to control the plant.

- For more information, contact SYSTEMS at (563) 568-6387 info@systemsquipment.com.