Asphalt Product Gallery: December 2016

BY AsphaltPro Staff

AsphaltPro sets the standard for equipment and service information by focusing on what’s new in the industry. This product gallery focuses specifically on the production branch of our industry. Let’s take a look at the latest launches and upgrades that can influence and enhance your bottom line when it comes to the production of aggregates, binders and mixes. We’ll start with the team at Standard Filter Corporation, Carlsbad, California, and a technological advance you may have heard of already. Just this summer, a large asphalt contractor committed to using MIXLink at more than 100 of its plants across the nation, but the process began about six years ago. David Burig of Standard Filter Corp shares.

Plant Sustainability Migrates to the Cloud

In 2010, California’s South Coast Air Quality Management District (SCAQMD) implemented rule 1155, which mandated bag break detection devices on all hot mix asphalt (HMA) plant baghouses. With that ruling came regular inspections and the mandate that records be kept on-site to verify compliance. According to the ruling, the records must be “available immediately to the Executive Director of SCAQMD upon request.”

In 2012, Toby Wiik, president of Standard Filter Corporation, was speaking to a plant supervisor in Los Angeles about the onerous nature of the reporting and record keeping requirement. Wiik had seen a small PLC that could gather baghouse data and send SMS text messages. He then developed a program to send those messages to a server in the cloud. After successfully petitioning the SCAQMD to accept cloud data in lieu of on-site paper records, he launched the automated baghouse monitoring and record keeping system called DustLink.

Soon the plant owners asked if the system could keep track of other things, such as tonnage, burner fuel consumption and motor kW draw. The next logical step was to use this data to calculate plant efficiency in BTUs per ton, and the system evolved into what is now MIXLink. It tracks all of those key metrics and more, and they can be seen in real time from any computer or mobile device, and the data can be saved for immediate retrieval from anywhere. MIXLink will work on all OEM control system, acting as a bridge to unify data across all platforms.

“A plant manager can now sit in his office and see how efficiently all of his plants are running in real time,” Wiik said. “And at the end of each run, key efficiency indicators are logged on a summary page, that allow management to analyze the run at a glance. A detailed Excel spreadsheet is also generated, storing every aspect of the run in five-second increments.”

By clicking on a saved run on the summary page, users can bring up a graphic representation of that particular run. Efficiency can be compared from run to run, or from one plant to another. You can also compare the cost of the mix you just ran to the historical average for that mix.

This illustration is a graphic representation of key plant metrics during a day’s production. Temperature, tons per hour, BTU per ton, kW demand, theoretical efficiency, AC use in tons per hour and as a percentage of mix, are all shown.

Let’s consider efficiency. Every plant has its sweet spot—the rate at which it runs with the highest efficiency. But plant operators may not know where that spot is. MIXLink allows operators to see their efficiency on a flat screen in the control house, in terms of BTUs per ton and actual dollars per ton. Now operators can set visual target efficiency goals, basing them on the mix they’re running, so they have something to shoot for. Operators can tweak their run for more efficient operation as it’s happening. Real world data shows a reduction in fuel consumption of up to 20 percent when an operator can see the efficiency at which he’s running.

We tend to focus on burner fuel when we think about HMA plant efficiency, but power and demand charges can be reduced significantly if they are properly managed. How much does it cost to run your baghouse exhaust fans during an hour-long hot stop? MIXLink allows you to see the instantaneous and historical electrical current draw for your plant as a whole, or you can look at key power consumers individually. If a drum drive motor starts pulling more current than it usually does, it may be a sign that it hasn’t been lubricated, or a bearing could be going bad. Whichever it is, alarms can be configured to send notification via text message or email to the recipient of your choice when any parameter goes outside of user-defined limits. Alarms can be set for any parameters being monitored, including motor current, mix temperature, or if the ratio of AC to aggregate goes outside of recipe parameters.

When the last truck is loaded, there are reports to do. MIXLink can take the data gathered during the day’s production and create customized reports that fit the owner’s needs. MIXLink also captures and archives production data for access days or years later—this includes mix temperature, AC content and even weather conditions at the time a batch was made. Because the data is stored securely in the cloud, authorized users can access it at any time, from any computer or smart device.

MIXLink has grown to what it is today through customer input. These measurable data points are the points HMA producers have requested. The construction materials industry is already embracing cloud-based plant connectivity.

- For more information, visit standardfilter.com.

CEI Enterprises has added a second line of hot oil heaters, the CEI helical coil heater pictured on the right.

From CEI Enterprises

In addition to its well-known and established line of jacketed firebox hot oil heaters, CEI of Albuquerque, New Mexico, now also offers a new line of helical coil heaters. Standard helical coil modules feature two-pass design in outputs ranging from 1.2 million to 4 million BTU/hour. Larger sizes, as well as three-pass designs and vertical models are also available.

The helical coils are designed and built to ASME code. They are designed to provide a large heat transfer surface area, low flux rates, and an idea fluid velocity of 7 to 11 feet per second. ASME stamp is available as an option.

Both lines of CEI hot oil heaters feature UL-rated, NEMA 4 control panels as standard equipment. These panels provide watertight protection against splashing water, hose-directed water, rain, sleet, snow, ice, dirt and windblown dust. Panels that meet CSA specifications, and other NEMA standard enclosures are available optionally.

An extensive number of options for enhanced fuel efficiency and multiple thermal oil circuits are available for both lines of CEI hot oil heaters.

- Use this at the tank farm.

- For additional information, contact CEI at (800) 545-4034.

The Round Super-Tall HD Building from ClearSpan is built to accommodate equipment working beneath the structure.

From ClearSpan

ClearSpan Fabric Structure, South Windsor, Connecticut, presents its Round Super-Tall HD Building for applications where equipment and machinery needs to be operated within the structure. The building comes in three sizes that can be customized to meet building requirements. The 25-foot, 8-inch tall building is 43 feet wide. The 30-foot, 11-inch tall building is 52 feet wide. The 34-foot, 2-inch tall building is 62 feet wide. Each size can be built as a free-standing structure or on pony walls.

The structures can be engineered to meet local building codes. Round Super-Tall HD Buildings are built with durable, triple-galvanized steel. The frame is made in America, and it is covered by 12.5-ounce, 24-mil rip-stop polyethylene fabric. The fabric covers are UV resistant and come in the customer’s choice of four colors.

- Use this in the plant yard.

- For more information, contact ClearSpan at (866) 643-1010.

The tandem bin set-up of the Portable Longneck Recycle System from CWMF directly feeds RAP into the recycle collar of the drum.

From CWMF Corp

The Portable Longneck Recycle System from CWMF Corp originally rolled out in 2009, but it’s been updated in 2016 with a custom, two-bin set-up that went to a client in June. The portable longneck recycle system directly feeds RAP into the recycle collar of the drum. It is available in single-bin set-up or a tandem bin set-up. A standard system would include a scalping screen and scale conveyor. It consolidates the typical recycle bin and scale conveyor set-up into one chassis. In addition, CWMF is able to incorporate a hammer mill system that will grind the oversized product coming off the screen. Quicker plant tear-down, quick set-up and less transportable loads are part of the design.

- Use this for RAP mixes.

- For more information, contact Travis Mick at (320) 267-3805 or travis@cwmfcorp.com.

D&H Equipment, Blanco, Texas, released its Heat Guardian heater and tank monitoring solution at the end of June 2016.

From D&H Equipment

D&H Equipment, Blanco, Texas, released its Heat Guardian tank and heater monitoring solution to the marketplace at the end of June. It was designed for owners, managers and operators to remotely monitor their hot oil heating systems and tanks. It provides real-time data to the user by text, web-based monitoring, as well as the full color touchscreen panel display, and includes the capability to send configurable text alerts based on user input variables.

Each Heat Guardian monitors events including power loss, a hot oil heater’s flame fault and oil temperature, and up to three tanks’ temperatures and levels. Receiving an alarm or getting the current system status is as easy as sending a text, according to the manufacturer. A built-in battery backup will allow the unit to alarm you even in the event of total power loss at the plant.

- Use this to monitor your tank farm.

- For more information, contact Jason Cox at (830) 833-5366 or sales@dhequip.com.

Eagle Crusher Company’s latest product innovation is the UltraTraxx™ portable impactor, equipped with the company’s UltraMax® UM-15 impactor.

From Eagle Crusher Company

UltraTraxx™, Eagle Crusher Company’s latest product innovation, came on the market May 2016. This portable impactor track unit, equipped with the company’s UltraMax® UM-15 impactor, is designed for ultra-mobile crushing on the job site.

UltraTraxx has fuel capacity for more than 10 hours of operation. The UM-15 impactor provides the industry’s only lifetime rotor warranty (North America only) on its solid-steel, three-bar, sculptured rotor for minimum downtown. The load-sensing hydraulics improve fuel efficiency and reduce component wear for lower operating costs and minimum downtime as well, according to the manufacturer. Tthe all-hydraulic, hydrostatic-drive system allows independent operation of the conveyors, feeders and impactor. Material processing efficiency is maximized by the UltraTraxx smart feeder drive system by monitoring engine load for more efficient production and product consistency.

To help ensure the highest quality spec product, UltraTraxx is equipped with a permanent, cross-belt magnet to remove steel contaminants from crushed material. The magnet is reversible to allow steel to discharge from either side of the unit, and the magnet does not need to be removed for transport.

The UltraTraxx heavy-duty hopper is sized for feeding with a loader or excavator, and the unit has a discharge conveyor height of 12 feet 5 inches for feeding directly into an optional screener.

The UltraTraxx includes a wireless remote control to operate and monitor plant functions including filter status, hydraulic oil temperature, engine load and charge pump pressure.

- Use this to crush material.

- For more information, contact Eagle at (800) 253-2453 or sales@eaglecrusher.com.

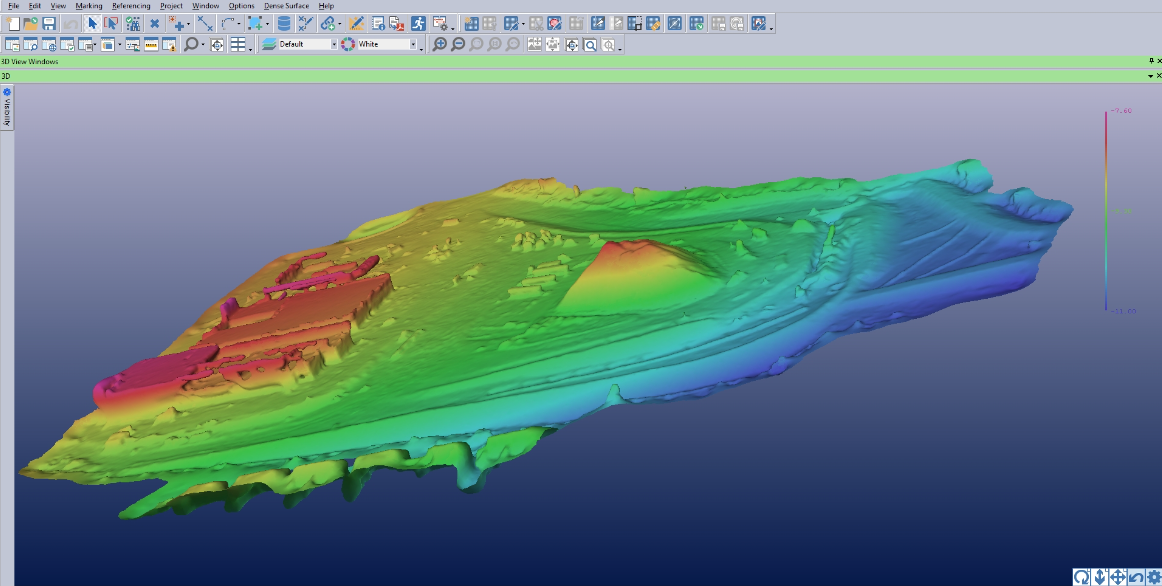

PhotoModeler UAS 2016 software includes features that provide higher performance in drone photogrammetry.

From EOS Systems

Eos Systems Inc., Vancouver, British Columbia, has introduced new photogrammetry software optimized specifically for photographs taken with drones—unmanned aerial systems (UAS). The new PhotoModeler UAS 2016 software creates 3D models, measurements and maps from photographs taken with ordinary cameras built-in or mounted on drones. It includes features for optimized operation with drone photos including post processing kinematics (PPK), volume objects, full geographic coordinate systems support, multispectral image support and control point assist.

The new version of PhotoModeler is suited for applications including surveying, ground contouring, surface model creation, stockpile volume measurement, mining and mine reclamation, and more, according to the manufacturer. Eos PhotoModeler was introduced 23 years ago and has become one of the leading photogrammetric software platforms.

- Use this for material management.

- For more information, contact Matt Klymson at (604) 732-6658.

The Recon™ monitor system from Heatec was introduced in late 2015.

From Heatec

Heatec says that managers of asphalt facilities in the United States and Canada are showing a remarkable response to the Recon™ monitor system that the company introduced in late 2015. The Recon system enables plant personnel to remotely monitor the live status of asphalt heaters and asphalt storage tanks at their HMA plants. Operators use this information to avoid unwanted shutdowns due to heating problems. And they keep close watch on asphalt use and inventories to better plan tank refills.

The Recon monitor shows heater alarm status, hot oil temperatures, asphalt tank temperatures, tank liquid levels and tank mixer on-off state. Operators can use a smartphone, tablet or PC to access the system.

- Use this at the tank farm.

- For more information, contact Heatec at (423) 821-5200.

Honeywell Thermal Solutions has introduced the Hauck BCS 7000 control system for asphalt and aggregate drying systems.

From Honeywell Thermal Solutions

Honeywell Thermal Solutions, Rockford, Illinois, has introduced the Hauck BCS 7000 control system for asphalt plant and aggregate drying systems. It is the successor to the Hauck BCS 6000 control system. Each BCS 7000 control system is designed to provide completely integrated control for temperature control (either material temp or exhaust gas temp), draft control and flame supervision. The Hauck BCS 7000 is designed to be applied to virtually all burners used in the industry including all models of Hauck burners as well as other combustion systems by various manufacturers.

Producers can expect to see simplified operation, easy set up and thoughtful integration of burner set up through the controls, according to the manufacturer. Additional features include advanced diagnostics for burner status, safety limits and indication of all critical inputs and outputs. The Hauck BCS 7000 employs higher power PLC processing for advanced functions and speed required for control of multiple outputs necessary in the control of both simple single-actuator burners as well as multiple output low emissions burners.

In addition to the enhanced burner control functions, the Hauck BCS 7000 control system also has network connectivity via Ethernet and can be connected to mobile devices as well if necessary. Hauck BCS 7000 control systems include ultra violet flame detectors, authentic Hauck Rapid-Response thermocouples and an exhaust air flow switch.

- Use this for asphalt production.

- For more information, contact Paul Lavenberg at (717) 644-5446.

Meeker Equipment announces the shipment of its latest 500 TPH drag conveyor.

From Meeker Equipment

Meeker Equipment announced it recently shipped a 500 TPH drag conveyor to Virginia. The conveyor features a 50-inch deep cambered main frame, 1-inch thick Ni-Hard floor and wall liners solidly cast. The reject chute opens 100 percent, allowing for complete drop out of rejected material. All sprockets on the conveyor, including idler sprockets, are segmented for easy maintenance. As standard, the conveyor comes with chain tensioning indicator to notify operators that it is time to tighten chain. All chain adjustments are done on the top side of the conveyor with hydraulic pump. Chain adjustments on the bottom allow the point of entry of the asphalt to the drag conveyor to change causing wear. Meeker conveyors feature 6-inch pitch chain with ¾- x 8-inch tall slats. Conveyors are available in hot oil heat (all the way to the top) and electric heat.

- Use this for asphalt production.

- For more information, contact Jeff Meeker at (717) 667-6000.

PHCo Lo-Density unitized storage tank heaters are designed to be installed into any horizontal or vertical above-ground tank or vat.

From Process Heating Company

Process Heating Company (PHCo), Seattle, continues to offer its Lo-Desnity® electric heat for asphalt producers in the unitized storage tank heaters, fuel-oil preheaters and hot-oil heaters. With fluctuating energy prices, efficiency becomes critical to the cost of doing business. Electric heat offers 100 percent energy efficiency throughout the lifetime of the heater, because all of the energy is used to heat. PHCo electric heaters typically last for more than 30 years, providing 100 percent efficient heat over their entire lifetime, according to the manufacturer. In addition, electric heaters can be interfaced and coordinated with other electrical equipment so that the load of the heaters can be reduced to base rates, thus preventing increased demand charges or peak-use rates, and lowering consumption cost.

PHCo’s unique drywell-style heaters are designed to dissipate controlled heat as low as three watts per square inch on the heater’s sheath to prevent coking or damaging of temperature-sensitive asphalt, oil and emulsion materials. Because the drywell-style elements are accessible from outside of the tank, they also may be serviced without draining the tank. Electric heat is environmentally positive because it heats without combustion or emissions.

- Use this at the tank farm.

- For more information, contact Rick Jay at (866) 682-1582.

Rotochopper launched the TS-2 this summer.

From Rotochopper

To help customers capitalize on growing opportunities in recycling markets, Rotochopper has launched a new line of industrial slow-speed shredders. The track-mounted diesel TS-2 made its debut at Expo Richmond in Richmond, Virginia. The TS-2 is an aggressive dual-shaft shredder designed to pre-process stumps, commingled C&D, railroad ties, and other forms of mixed or contaminated waste.

Boasting simplified operation, streamlined maintenance and rugged reliability, the TS-2 features an open shredding table, allowing dirt, stones and other abrasives to pass. Paired with easily accessible routine maintenance areas, the TS-2 avoids the complicated upkeep often associated with slow speed shredders.

- Use this for recycling.

- For more information, contact Monte Hight at (320) 548-3586.

The RAP Eater™ from Stansteel is designed for efficient thermal heat transfer even when running high percentages of RAP.

From Stansteel

Stansteel® introduces the RAP Eater™ drum for heating, drying and mixing. The RAP Eater drum provides the asphalt producer a jump of two or three generations in technology with a relatively simple changeout of the drum, according to the manufacturer. It is designed for excellent thermal heat transfer and efficiency when running up to 50 percent recycle, while maintaining quality mix product.

- Use this for running high-percentage recycle mixes.

- For more information, contact Stansteel at (502) 245-1977.

From Stockpile Reports

Stockpile Reports, an inventory management system companies use to measure volume and tonnage of materials via drone, plane and iPhone-based measurement tools, released its new Verified Measurements feature June 13, 2016.

Stockpile Reports’ Verified Measurement feature gives a confidence score to each one of the stockpile measurements at construction and aggregate producer sites. When stockpiles are measured, there can be all kinds of measurement risks. Vegetation growing on the pile, standing water, equipment obstructions and more, all can cause big errors in a company’s inventory numbers. The Stockpile Reports system automatically highlights those risks, so companies can always have the insights they need to know whether to have crews do some pile cleanup and re-measure. Companies can almost eliminate write-offs and costly budget overruns.

- Use this for product management.

- For more information, contact Maury Margol at (425) 285-4303.

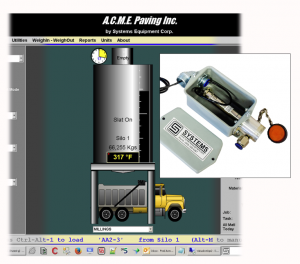

This screen capture example shows the 1292 Material Temperature Capture at Time of Load, the newest companion product to System Equipment’s loadout system, the WIN-LC3000.

From Systems Equipment

SYSTEMS Equipment has announced the release of the 1292 Material Temperature Capture at Time of Load, the newest companion product to the company’s Windows-based loadout system, the WIN-LC3000. Product conception was spurred by feedback from both producers and end-users in the asphalt industry with a common objective—to have an efficient way of measuring and documenting the temperature quality of hot mix being used for any given job.

The 1292 assembly consists of a PLC and two modules to be mounted in the control center (with an optional enclosure), as well as a probe and housing assembly that is mounted to each loadout silo (or drum, if used with the blend system).

Asphalt plants employing this technology have the unique position of being able to measure and document asphalt temperatures at time of load, as well as adjust temperatures with better precision for ongoing production based on feedback from pavers applying the product.

The 1292 includes a single infrared probe protected by an enclosure measuring approximately 4.5 inches high by 3 inches wide by 3 inches deep. One probe per silo is required. When used in tandem with the loadout system, the active end of the probe is mounted to the loadout silo frame and directed toward the truck bed. A small air valve incorporated into the enclosure prevents debris from attaching itself to the end of the probe and skewing the reading. As loading proceeds, the probe measures the temperature of the newly loaded asphalt mix. The temperature reading is both stored in the loadout database and printed on the driver’s loadout ticket.

The 1292 assembly can also work cooperatively with the blend system, capturing material temperature as the asphalt mix exits the drum. Due to the thick metal housing on traditional temperature measurement units, getting an accurate reading takes time as the heat must work its way through the housing and to the probe. “With the 1292 assembly, the reading is almost instantaneous,” Fred Axmear, software engineer at SYSTEMS Equipment Corporation, said. “This is particularly helpful with small batches, and also improves reaction time when temperatures need to be adjusted because feedback is both quick and accurate.”

- Use this at loadout.

- For more information, contact Systems Equipment at (563) 568-6387.

The A60H from Volvo features a max torque of 2,360 foot-pounds and a load capacity of 60.6 tons.

From Volvo

Volvo Construction Equipment, Shippensburg, Pennsylvania, introduced the A60H articulated hauler for use in the quarry, at the recent MINExpo. Powered by a 673-horsepower Volvo D16J engine, the A60H includes active hydraulic front suspension, hydro-mechanical steering and high ground clearance at the articulation joint. It features automatic traction control and 100 percent differential locks. It includes hill-assist, which is a new safety feature that holds the hauler in place on steep slopes without the need to engage the parking brake. The feature is designed to automatically activate when the truck arrives at a complete stop on a hill, and is disengaged when the operator accelerates. The dump support system is designed to allow the operator to see the percentage side inclination of the truck and set allowable parameters for safe operation. On-board weighing now comes standard and is fully automatic. Three load indicator lights alert both the hauler operator and the excavator when nominal load has been reached and can warn the operators of overloading.

- Use this in the quarry.

- For more information, contact foster@volvo.com.