Rubble Master’s RM 120GO!

BY AsphaltPro Staff

When recycling on-site, paving contractors look for something quiet and compact. Rubble Master’s RM 120GO! Aims to answer that call.

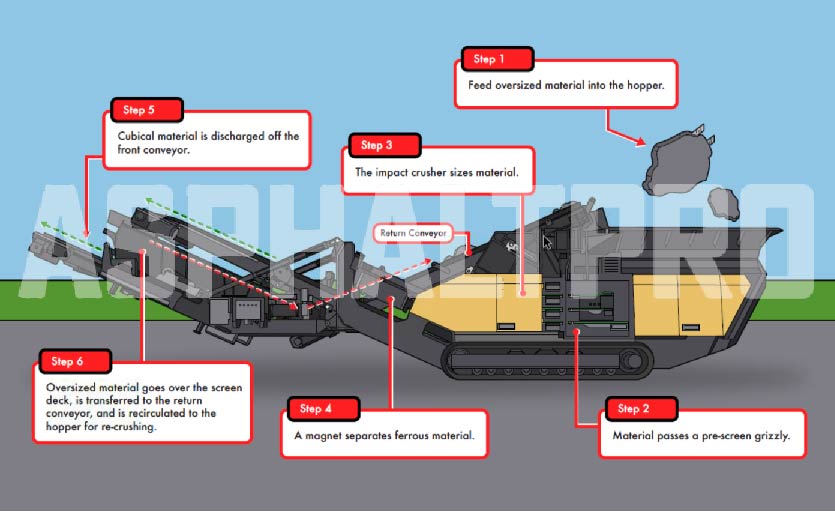

When recycling on-site, paving contractors look for something quiet and compact. The team at Rubble Master, with headquarters in Austria, began its line of mobile crushers in 1991 to answer that need. Specifically, the RM 120GO! offers production of up to 385 tons per hour (TPH), depending on the spec material needed. Here’s how it works.

First, an excavator feeds chunks of material to be sized into the 5.2-cubic-yard vibratory feed unit.

That material passes over a 36-inch by 61-inch prescreen grizzly bypassing fines to the main discharge conveyor. Oversize material goes to the 46-inch by 32-inch inlet opening to the crusher.

The four-bar impact crusher reduces the material to a cubical product and sends it to the main discharge conveyor. After the material passes the impact crusher, a magnet separates any rebar and ferrous materials. Material gets conveyed onto a 5-foot by 12-foot on-board screen deck to produce consistent, spec product. Oversize material goes over the screen deck, gets transferred to the return conveyor and is recirculated back into the hopper to be re-crushed. Spec material—such as ¾-inch base material—that falls through the screen box gets discharged in front of the machine.

Using approximately 8.5 gallons of fuel per hour, the mobile crusher is powered by a 400-horsepower John Deere, 6-cylinder engine.

As an option, the contractor can swing out the return conveyor for 90-degree stockpiling.

For more information, contact Rene Wagner at (219) 241-3820.