Pave, Maintain Safely

BY AsphaltPro Staff

While the June product gallery department will continue AsphaltPro Magazine’s focus on iron and services for the paving and pavement maintenance contractor launched around the CONEXPO-CON/AGG 2023 tradeshow and conference in Las Vegas, we’ve seen some important releases between the March event and press time. For example, the researchers at University of Houston and Durham School of Architectural Engineering and Construction, University of Nebraska-Lincoln, published in a recent Applied Sciences journal, “ViPER+: Vehicle Pose Estimation Using Ultra-Wideband Radios for Automated Construction Safety Monitoring.”

Those scientists—Alireza Ansaripour, Milad Heydariaan, Kyungki Kim, Omprakash Gnawali and Hafiz Oyediran—found the ViPER+ safety monitoring system for construction sites accurately tracked workers’ locations on job sites. Here’s part of the press release they shared with media April 20.

“The point of our research project was to enhance safety of workers and equipment on a construction site by tracking their location,” said Ansaripour, a computer science doctoral student at UH and first author of the study. “By tracking their location, we can monitor location-based policies related to the safety of workers and equipment in construction sites.”

These location-based safety policies are created during the planning stage of the construction site such as when Internal Traffic Control (ITC) plans are made. These policies define safe areas for workers and equipment or define a safe distance between them when equipment is operating in the construction site. ViPER+ automates the monitoring of these policies and detects any violations of the policies while workers and equipment are working.

ViPER+ uses ultra-wideband technology for location tracking. “These radios use large bandwidths to communicate, which enables them to perform location tracking more accurately compared to other wireless radios,” Ansaripour said. “This was the technology we used to track the locations of workers and equipment.”

The team’s ViPER+ system overcomes non-line of sight situations. These are instances in which trucks, construction loaders and other equipment block the signal between the transmitter and receiver in ultra-wideband radio transmissions.

Ansaripour and his colleagues implemented a correction method in their localization, or location tracking algorithm to reduce the error caused by non-line of sight.

Testing ViPER+ in Construction Zones

ViPER+ is an updated version of the group’s initial system ViPER. The greatest difference between the two is the enhanced location tracking on ViPER+, which is more accurate in non-line of sight situations.

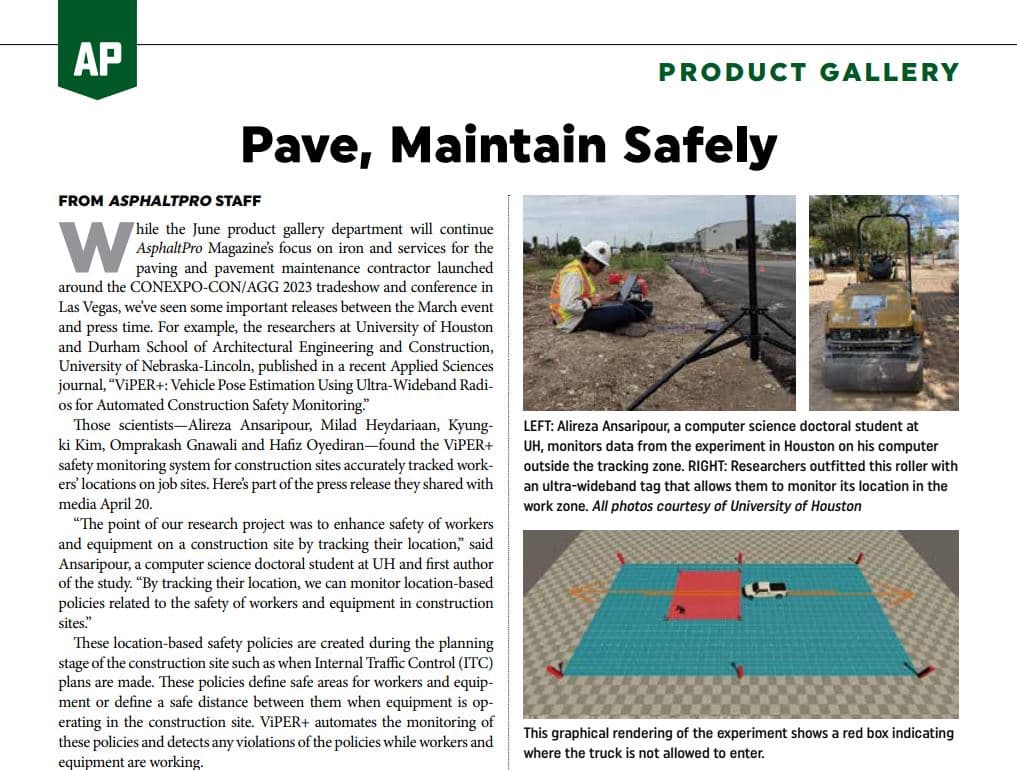

The team tracked locations through tags and anchors. Tags are small ultra-wideband radio transmitters, mounted to workers and vehicles to monitor their locations. Anchors are ultra-wideband receivers that receive signals from tags. The researchers then collected data from anchors to their computer server and estimated the location of vehicles and people in a construction site.

They tested their system twice in actual construction zones in Houston that were cordoned off for their experiment. But instead of real construction workers, students had to play that part.

“In our evaluation, all four construction workers had tags mounted. We also had one vehicle, either a truck or bulldozer with multiple tags on it, and another static vehicle was used to create a non-line of sight situation.”

The first evaluation was in 2019 when researchers set up tags in an area measuring about 8,600 square feet called the tracking zone. Four students operated as workers in the tracking zone while Ansaripour was managing the data flow of the system and made sure the experiment ran smoothly. In 2022, a similar scenario was set up but at a different construction site.

“Alireza is one of those students with brilliant ideas and the work ethic to see these ideas to fruition,” said Gnawali, associate professor of computer science at the UH College of Natural Sciences and Mathematics and co-author of the study. “Having that combination is important to get these technical projects to be successful.”

Future Improvements

Future changes to the system include ironing out user design issues such as alerting construction workers when they are too close to moving machinery.

“We also have an issue creating a tracking zone that covers all of a construction site, not just a portion of it,” Ansaripour said. “There are still some improvements that need to be made for this to become a commercial product, but our work provides insight on how a real-time safety monitoring system can be used for safety tracking in construction sites.”

Other authors of the study include UH’s Heydariaan, and from the University of Nebraska-Lincoln, corresponding authors Kim and Oyediran. This research project was funded through the National Cooperative Highway Research Program (NCHRP) Idea of the National Academy of Sciences under the award NCHRP-206.

Astec Industries Displays New Generation of Tracked Highway Class Pavers

CASE Construction Equipment Announces E Series Compact Vibratory Rollers

Road Widener LLC Displays FH-R Material Placement Attachment