Luck Stone Corporation’s Drone Program Reveals New Efficiencies for Luck

BY Thomas Nicholls

Luck Stone Corporation, headquartered in Manakin Sabot, Virginia, is a family owned and operated construction aggregates company that has demonstrated a commitment to innovation in all aspects of operations for almost a century. Investing in drone technology was a logical and strategic step for management. Recently, Luck Stone has been using unmanned aerial vehicles (UAVs) powered by the aerial intelligence platform from Delair, headquartered in Toulouse, France, to transform the company’s business decisions and environmental footprint.

As a producer and supplier of sustainable aggregates for civil engineering, construction and environmental projects of all sizes, Luck Stone offers a variety of crushed stone, sand and gravel products sourced from its extensive quarry network in Virginia, Maryland, North Carolina, South Carolina and Georgia.

According to John Blackmore, survey and mapping supervisor at Luck Stone, drone data has proven its financial value by increasing efficiency and uncovering untapped reserves of aggregates. “Our fleet of UAVs can digitally map existing conditions and measure stockpile volumes for inventory management, production forecasts and more accurate auditing,” he said.

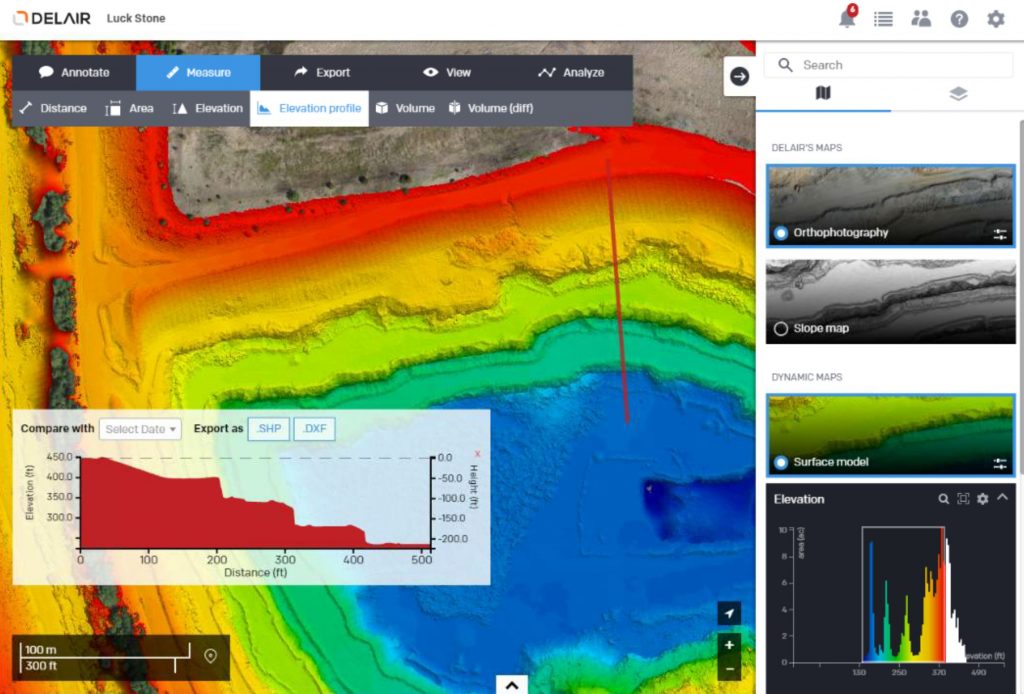

The Delair.ai platform gives Luck Stone engineers a way to collaborate on a wide variety of decision-making purposes including volumetric measurements, safety inspections and pit efficiency analytics.

Prior to investing in UAVs, Luck Stone chartered planes to take aerial photos and collect information about site resources twice a year. Upon getting the images, the company made 3D models of the sites and then sent paper copies of the surveys to project managers in various locations, using overnight shipping to ensure that project data was shared in a timely fashion.

“With planes, our associates spent hours on manual surveys and days on data collection,” Blackmore said. “Drone data has helped us determine substantial quantities of reserves and, as a result, helped improve site design.”

As early adopters of UAVs, Luck Stone viewed drone technology as a solution to managing inventory; one skilled drone pilot could navigate the UAV to fly over a quarry pit and survey resources from a birds-eye vantage point. Additionally, the mining-specific analysis tools that the Delair.ai platform offers are helping the company harness the full potential of aerial intelligence within the business.

Now, site inspections and inventory updates can be done as frequently as four times a year and are done monthly at some sites. UAVs have the potential to quickly, precisely and safely map areas that were formerly difficult to access by foot, such as an elevated terrain in a quarry. Also, the ability to access and share job data in near real-time is a valuable business and communications tool for providing progress reports to various internal departments at Luck Stone.

“By sharing information with everyone involved in a specific project through the Delair.ai cloud platform, we can address issues related to quantities and costs much sooner,” said Chuck Stilson, mining engineering manager at Luck Stone. “We need to think in 3D and being able to visualize our plants with the Delair.ai platform is very helpful.”

Improve worker safety

While the drones are designed to collect data for computer analysis, they also offer flexibility. For example, the drone pilot can pause to take photos or videos of anything that might require closer attention and instantly share the information with engineers back at the office. Also, broader views of the territory around extraction pits help project designers to place safety berms more effectively in the excavation area.

Data collected by drones and analyzed by Delair.ai are used to create “digital twins” of Luck Stone’s assets and sites. This provides Luck Stone with a critical tool to reduce costs, improve safety and increase efficiency through its detailed analytics capabilities and collaborative architecture. Luck Stone uses the platform for real-time and in-depth analysis of sites and assets by engineers and project designers.

“Through our partnership with Delair, we have learned about the many different types of analysis that are literally at our fingertips now,” Blackmore said.

A pioneer of new technologies and processes, Luck Stone aims for the gold standard in worker safety. At the same time, expert engineers and surveyors must be provided with accurate, timely and detailed data. With drones, there is a reduction in time and survey costs; plus, Luck Stone’s project team no longer needs to traverse the quarries to gather data.

Additional benefits and insights

One of the most significant benefits of using Delair’s aerial intelligence platform with mapping technology is improved site surveying efficiency. Luck Stone uses UAVs for inspections, surveys, and mapping of current and future projects. From high above the Luck Stone operations, UAVs take hundreds of aerial photos that will be uploaded to the Delair.ai platform, ready for analysis by engineers and project designers. The business intelligence resulting from those images will be used for a wide variety of decision-making purposes including volumetric measurements, safety inspections and pit efficiency analytics.

Luck Stone makes use of the Delair.ai platform to manage, process, view, analyze and collaborate around aerial data. “We collect aerial imagery to make high-resolution maps and 3D models to visualize how they currently look and what they could look like in the future,” Blackmore said.

Additionally, UAVs have collected valuable information about truck routes and distances. This information is used to optimize Luck Stone’s on-site fleet of loading and hauling vehicles. Drone-assisted volumetrics have also been used to calculate how much overburden has been moved by contractors.

Data collected by drones and analyzed by Delair.ai are used to create “digital twins” of Luck Stone’s assets and sites. This provides Luck Stone with a critical tool to reduce costs, improve safety and increase efficiency through its detailed analytics capabilities and collaborative architecture. Luck Stone uses the platform for real-time and in-depth analysis of sites and assets by engineers and project designers.

Consequently, drone data enables the company to uncover new insights that can reduce costs. Such data can be harnessed to become consumable, actionable and shareable.

Planning new mining projects

Drone data has been instrumental in mining development projects. Detailed maps and contour surveys are combined with geological data to project scenarios and test out designs. Aerial imaging analysis enables Luck Stone to capture and analyze site detail at a more granular level, more than a ground-based survey team could do. The up-to-date, high-resolution, geo-localized images can then be transformed into actionable aerial data.

In a recent project, Luck Stone project designers used aerial intelligence from UAVs to choose the route of a road at a site. The optimized route protected significant aggregate reserves, ready to be extracted at a later date.

“It’s hard to even put a cap on what’s going to happen with drone technology and the people who are tapping into this,” said Eric Warinner, a UAV pilot for Luck Stone.

Companies in the construction and aggregates industry are moving toward a future where drones are used on every jobsite. For Luck Stone, integrating UAVs into the enterprise operations is not on a high-tech wish list—it is a business imperative.

Drone technology has permeated the fiber of Luck Stone’s decision-making by delivering cost savings, improving safety and increasing efficiency. In the days ahead, as hardware and software evolve with seemingly lightning speed, drones will continue to prove their value and be even more indispensable.

As Luck Stone embarks on a period of strategic, accelerated growth through expansion deeper into the Southeastern United States, the company has never compromised on its unwavering pledge to have a positive impact on people and the communities it serves. Drone technology powered by the Delair.ai platform is destined to play a critical role in Luck Stone’s continued pursuit for exceptional quality in its products and customer service. <endmark>

Thomas Nicholls is CMO at Delair, where he manages the strategic positioning and promotion of the company’s aerial intelligence solutions worldwide. Previously, he was executive vice president at IoT network pioneer SigFox.