How to Perform I-FIT

BY Sandy Lender

A number of thesis papers now stored in perpetuity online discuss cracking problems occurring after placement of flexible pavement mixes and how to discern when a mix could be subject to cracking upon placement. To prevent a mix from succumbing to a cracking failure, mix design technicians want to detect the problem and nip it in the bud. That means mix design technicians and researchers seek the Holy Grail of cracking tests.

In his thesis titled “Evaluation of Laboratory Cracking Tests Related to Top-Down Cracking in Asphalt Pavements,” submitted to the graduate faculty of Auburn University Dec. 10, 2016, and approved by David H. Timm, Randy C. West and Jeffrey J. LaMondia, graduate student Nathan D. Moore evaluated seven surface mixes using five lab cracking tests. He posited the semi-circular bend test (SCB) and Illinois Flexibility Index Test (I-FIT) “possessed the lowest variability” of the five lab tests. This article will show how to perform the I-FIT specifically.

Make a Specimen

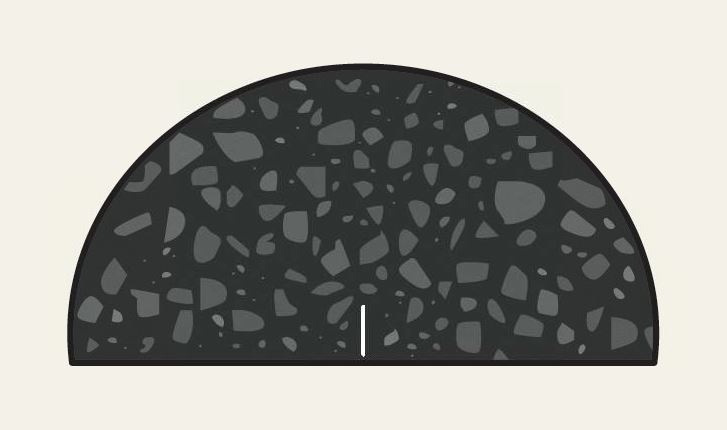

Begin with making your test specimen by placing the mix to be tested in a Superpave gyratory compactor (SGC). Compact the specimen to a height of 160 mm. Then trim the specimen to get two semi-circular specimens. Next, you will cut a notch in the base portion of the semi-circular specimen—parallel to the loading axis. The notch will be 15 +/- 1 mm deep and 1.5 mm wide. Take measurements. Finally, place the two notched specimens in a water bath or environmental chamber for two hours at 25 degrees C (plus or minus 0.5 degrees).

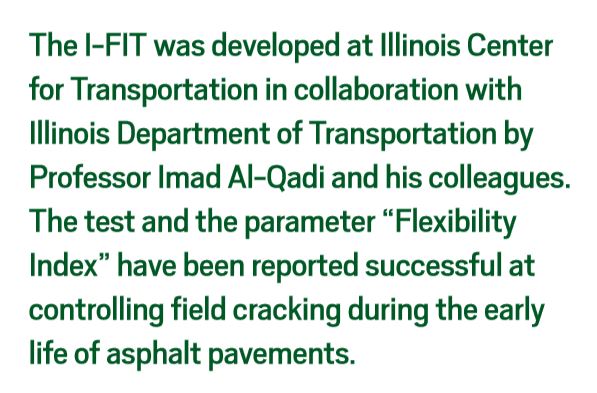

Lab personnel will cut a notch in the “base side” of the semi-circular specimen prior to placing it on the roll pins of the bending test fixture.

You can alternately cut a specimen from a core. You will want a 2-inch puck, which you will cut into semicircular halves and saw notches into as described above.

To be most efficient, technicians will likely make and work with more than one specimen at a time. Jean-Paul Fort, technical director of Colas Inc., USA, shared with the audience at the National Asphalt Pavement Association (NAPA) midyear meeting in Boston that Illinois Test Procedure 405 (and AASHTO TP124-16) requires multiple samples, and when four I-FIT specimens are tested from a lot, the one measuring furthest from the average is discarded. “This keeps outliers from skewing the average,” Fort shared with the audience.

Test the Specimen

Once you have specimens prepared, it’s time for testing. It may sound basic, but make sure the Ethernet cable is plugged into your computer. You will turn on your computer before turning on your bending test machine to allow them to communicate with one another correctly. With both of these on, you’ll launch the application software.

The Illinois Center for Transportation (ICT) at the University of Illinois, Urbana-Champaign (UIUC), developed the I-FIT testing device and the software to test specimens, and the following discussion comes from its instructional video here.

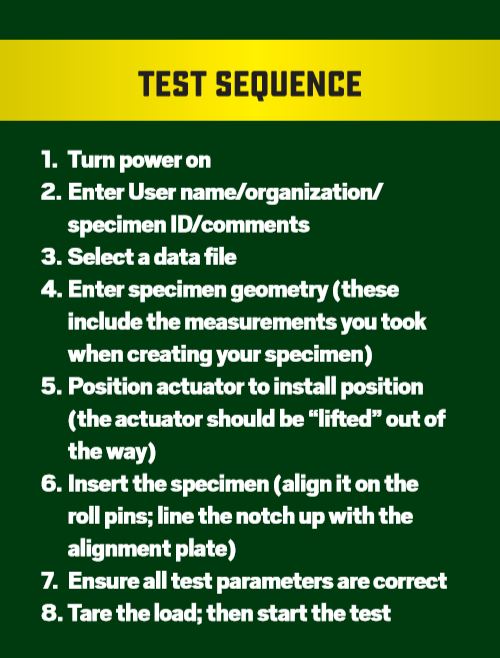

You launch the application by double-clicking on the IFIT icon on the desktop. The window that opens will allow you to select a parameter file—you can select the default. The main page in front of you at this time will give you a list of the test sequence.

Place and align the specimen in the bending test fixture so that the load presses against the top of the semicircular curve. The load line displacement control will press at a rate of 50 mm per minute. As the SCB fractures, a smooth load displacement curve, which results from gradual crack propagation, is recorded and used for analyzing the test results. The SCB analysis tool takes into consideration two elements: fracture energy and slope at inflection point.

When the test is complete, the actuator will move back to the start position and the hydraulic pump shuts off.

On the screen before you, you’ll see a summary of the test results, including the peak load, time at peak load, etc. To run another test, you will click the “reset” button. To calculate the Flexibility Index (FI), you post-analyze the data.

Interpret Your Result

The FI tells you the degree to which your mix design, thus your pavement, can resist premature cracking. “In general, the larger the FI number, the more resistant the mixture is to premature overall cracking-related damage,” according to the ICT researchers. Graduate student Moore listed a complex equation for technicians to plug numbers into. Companies such as TestQuip have developed software that takes data automatically from one screen to an algorithm to produce results. And the originators of the IFIT, ICT researchers, also provide software you can download here to get automatic results.