Industry Incorporates Sustainability at Asphalt Production Plants – Part II

BY Malcolm Swanson, P.E.

Editor’s Note: The asphalt industry works with sustainable practices to lower GHGs and keep an already low carbon footprint in check. Malcolm Swanson, P.E., gathered information for an 11-page document outlining some of the industry’s sustainable practices. Part I of the piece appeared in the July edition of AsphaltPro; here we’ll share Part II of Swanson’s paper, in which he gives a deep dive into additional ways to reduce combustion source emissions while reducing your fuel spend at the asphalt plant. Part I is available here. Part III is available here.

Although discussions of energy and materials are going to necessarily intertwine, we focus on energy in this part of the article series. We mentioned in Part I that better combustion, for the purpose of reducing NOx emissions also resulted in reduction of all other emissions, including carbon dioxide, a well-known greenhouse gas (GHG) and, at the same time, resulted in a reduced fuel spend for a contractor in California. Here are some more ideas plant managers can implement to save costs and enhance environmental sustainability.

Control Exhaust Gas Temperatures

Better thermal energy efficiency is tied directly to exhaust gas temperature. Better thermal energy efficiency means less fuel will be burned and fewer emissions produced. Asphalt plant exhaust gas temperature is typically around 250 degrees Fahrenheit but, with 5 percent moisture in the incoming materials, dew point is about 160 degrees Fahrenheit, which is almost 100 degrees lower.

By reducing the exhaust gas temperature to something around 170 degrees Fahrenheit, the temperature gap is reduced to 10 degrees, instead of 100. That change results in a fuel purchase reduction of about 6 percent and a similar reduction in exhaust gas volume, reduction in all combustion-source emissions, and an increased production capacity.

We now have the technology to measure incoming aggregate and RAP moisture contents and to use the data as input for real time calculation of exhaust gas dew point by an algorithm embedded in the plant control computer program. Astec’s V-Pack system, for example, is driven by the algorithm output and can be used to continuously adjust dryer drum speed to control exhaust gas temperature to maintain it just above the dew point.

Asphalt Industry Incorporates Sustainability at Asphalt Production Plants – Part I

Although almost all plants could tolerate some reduction of exhaust gas temperature with no problem, operating with the exhaust temperature too close to dew point will cause mud to form on the walls of the baghouse and on the bags. The greatest advantage of this technology can be realized when applied in conjunction with a good insulation system for the exhaust ductwork and the baghouse.

Look inside the dryer at the flights, which lift virgin aggregate from the bottom of the drum and drop it through the stream of hot gases coming from the burner. Some flight designs don’t produce a uniform distribution (veil) of aggregate across the full diameter of the dryer drum, except possibly when the dryer is fully loaded. When incorporating more than about 30 percent reclaimed asphalt pavement (RAP) into the mix, obviously the virgin aggregate component is less than 70 percent of full capacity. The more RAP in the mix, the less full the dryer is.

Source: Astec Industries

As the dryer drum rotates, flights that aren’t full won’t shower the aggregate on the uplift side of the drum. That leaves an unobstructed exit path for the hot burner combustion gases. The hot gases will take the path of least resistance, bypassing the aggregate that is showering on the down side of the drum, and taking the heat with them. Although the superheating of the virgin aggregate usually gets the blame for a hot baghouse, it’s actually the incomplete aggregate veil that has caused the problem, wasted fuel and reduced production capacity.

This was the main reason the V-Pack™ system was developed. The flights used in that system have deep v-shaped cuts in them that enable them to produce a complete aggregate veil whether they are lightly or fully loaded. A complete veil prevents heat from escaping via the path of least resistance.

Maintaining the dryer and exhaust system in good condition and keeping the burner properly tuned avoids wasting fuel. Tuning the burner with a properly calibrated combustion analyzer will inevitably result in fuel savings. Wasting fuel always results in a higher fuel spend and increased emissions. Worn dryer flights and damaged or missing drum seals have the same negative effect. Leakage air, whether it gets in through missing seals or worn holes, absorbs heat and takes it away from its intended use and makes it necessary to burn more fuel.

Industry Incorporates Sustainability At Asphalt Production Plants – Part III

Stockpile Sustainability

The lowest cost and most renewable of available resources are gravity and sunshine. They are resources that can be used to reduce the fuel spend and increase production capacity without the slightest concern about depleting them. In fact, the only way they can be wasted is to make no effort to optimize their use.

When aggregate and RAP are stockpiled on paved surfaces, sloped away from the feed bins on a 6 percent grade, much of the water that naturally accumulates in piles will be removed by gravity drainage. This conserves fuel and enhances production capacity more than almost any other available option. The paved surface under the stockpiles also prevents perfectly good aggregate from sinking into the ground over time and effectively becoming lost. In areas like the southeastern United States with a lot of annual rainfall, covering stockpiles can make a lot of sense, too. Again, this is an economically advantageous means of conserving resources, fuel, aggregate and RAP, as well as reducing GHG emissions.

Assess Temps

In the first part of this series, we showed that producing WMA in place of hot-mix asphalt (HMA) lowers fuel consumption and reduces all combustion-source emissions because of the lower mix temperature. It should be obvious that this is a good thing. The advantages of being able to get better asphalt cement coating on aggregates, store mix longer, haul longer distances, have mix that remains in a workable condition longer and have mix that is more easily compacted add to the clear evidence that paving with WMA is a smart business move.

There is always the FOB customer who will want mix at a high temperature. (You might be better off without that customer.) To avoid loss of margin, you have to get a premium for that mix not just because of the additional fuel burn but also because the additional exhaust gas volume slows your production rate and causes a larger amount of fixed plant cost for the high-temperature mix than for normal temperature mixes. Of course, additional emissions are created. Best practice, for many reasons, is to avoid overheating the mix.

Store It

Having the ability to store finished paving materials in silos enables plant operators to run continuously and at higher production rates, thus increasing plant efficiency. As with other efficiency improvements, this implies reduced energy consumption that translates to lower GHG emissions. Sustainability is further improved by reduced wasting of materials. Starting and stopping wastes fuel and materials. An additional factor is the positive effect on the consumption of diesel fuel by trucks while they wait to be loaded. If the day is started with filled silos, trucks have less wait time and burn less fuel, producing less exhaust gases.

Renew the Energy

Using biomass fuel to provide heat to the asphalt plant aggregate dryer is attractive because biomass is fully renewable and carbon neutral. While biomass burning does emit carbon dioxide, re-growing the source plants reabsorbs it. Environmental groups consistently oppose the use of biomass fuels based on the misconception that their use will consume forests. In reality, many forests are privately owned and only exist because the owner grows the timber for profit.

Without that opportunity, the owner (tree farmer) would remove the trees and grow some other crop on the same land. There are at least three avenues that could be traveled to get to biomass-fired asphalt plants. The first of these is to burn wood chips in a furnace and use the hot furnace exhaust gases as the heat source for the aggregate dryer. All of the necessary equipment and technology for this is either currently available or can be developed in a reasonable period of time. It would probably be best to run any plant configured this way as a 24-hour per day operation, because startup and shutdown of the furnace would require at least several hours. However, capital cost is too high.

Another way to use biomass is to reduce the fuel to fine particles and burn it as dust in a suspension burner. The Astec Biomass Burner does this in a rotary dryer. The catch with this approach is that there is no really good and readily available technology to prepare the fuel. Hammer milling is too expensive and the only other way to get there is by steam explosion of the wood fiber. This technology exists and is advancing, but isn’t ready yet on a scale that would support this demand. However, it’s being developed for use in utility power plants. Once it reaches a level of production to be viable in that industry, asphalt plant demand would be a small side market.

If a plant is in close proximity to a furniture factory or other industry that produces sander dust, that can be a source of small enough particle size to burn in the Astec Biomass Burner.

Source: Astec Industries

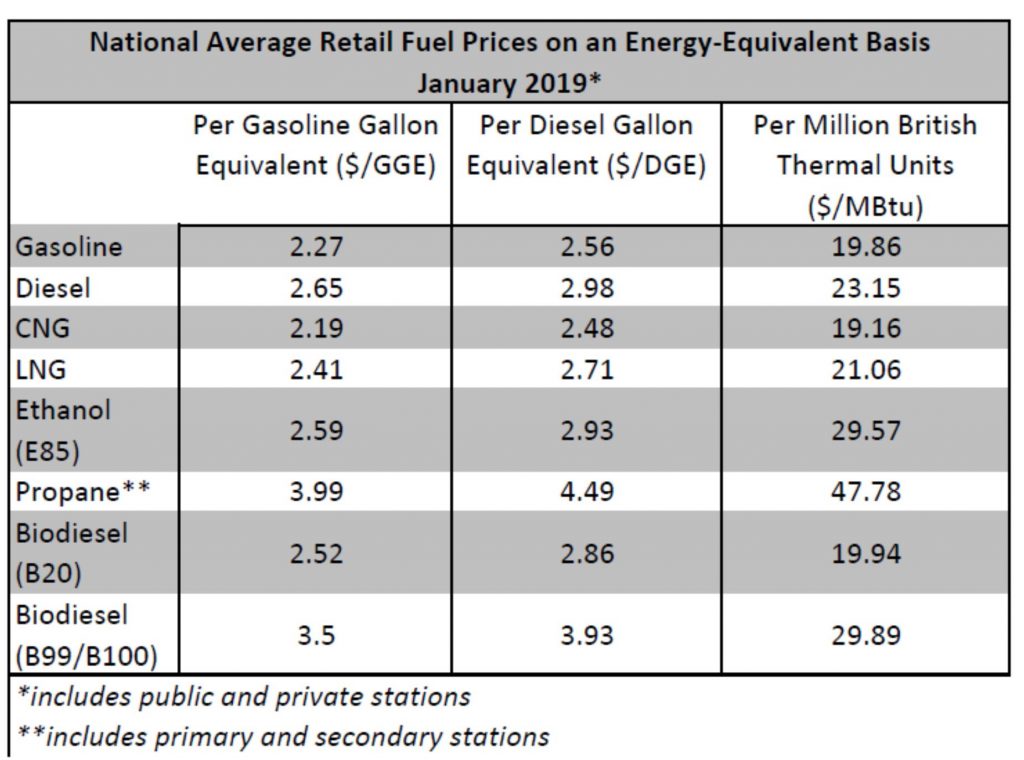

Lastly, there is biodiesel. See the table above for comparison of biodiesel to other fuels. Biodiesel is obviously renewable because it comes from plant sources. B20 biodiesel is a blend of 20 percent biodiesel and 80 percent petroleum diesel. B100 biodiesel is 100 percent biodiesel.

The other major energy form used by asphalt plants is electricity. With most utility companies you can ask and learn how much of your electricity comes from renewable sources such as wind, hydro and solar, and how much comes from fossil fuel sources and nuclear. You may even be able to request and receive more of your electricity from renewable sources. Whether you can go that route or not, there are many things that can be done, with respect to electricity use, to operate in a more sustainable manner. Here are some of those.

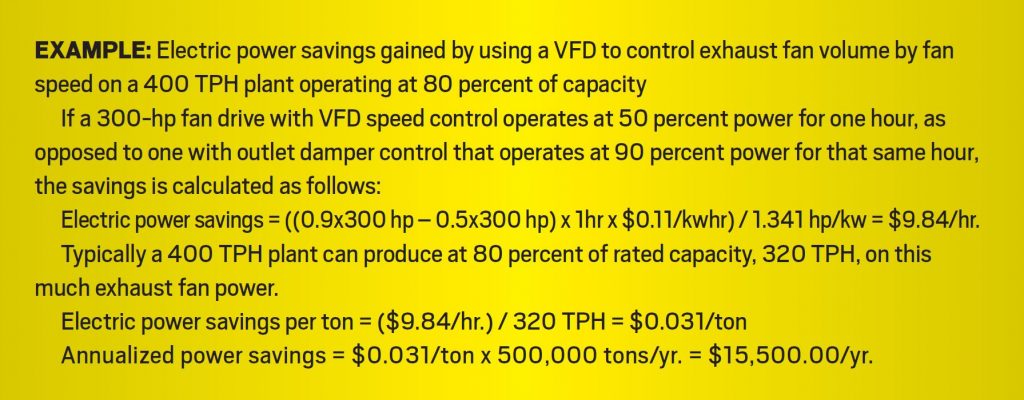

Using variable frequency drives (VFDs), along with fan motors, has a significant payback (see the case study here). Without using a VFD on the plant exhaust fan, the fan must run at 100 percent all the time, even though that’s not necessary; plants frequently operate at production rates below maximum capacity. An exhaust fan damper reduces the power consumption a little, but nothing like the VFD.

Typically, the next largest fan employed at an asphalt plant is the burner blower. A proportional energy savings is available there, but caution must be exercised. Most burners are not designed to operate with variable blower speed. Never apply a VFD to a burner blower unless the burner was designed to operate with variable burner blower speed. To do so could cause damage to the burner or worse.

Using VFDs for drag conveyors and other equipment may still be an advantageous thing to do to improve the plant power factor and for reduction of wear rates on wear liners, chains, etc. Reduction of wear is important in itself because worn parts have to be replaced. Of course, a worn steel or cast iron part can be recycled, but the part of it that has been worn away cannot. The sustainability of iron and alloying metal resources is connected to wear, as is the cost of replacing the part. Proper lubrication is an important factor in minimizing the wear rate of many components of asphalt plants.

Consider premium efficiency motors as well. On average, premium efficiency motors save about 3 percent electric power consumption as compared to standard efficiency motors. While that may not sound like a lot, anything that reduces electric power consumption without an offsetting increase elsewhere improves sustainability overall and reduces the size of the power bill.

Use a soft start starter where VFDs are not particularly advantageous. A soft start reduces the current inrush when a motor is being started. This can reduce the demand charges that are associated with instantaneous load on the grid. Most electric power utilities add “demand charges” to the power bills of users that have big inrush events, such as starting a big motor across the line, because they have to over generate to absorb those drains on the grid while maintaining system voltage above a certain low limit.

If there is sufficient land area, wind and sunlight hours, the asphalt plant power source can be complemented by onsite renewable power generation such as solar and wind power. When the plant isn’t operating, at most locations, the power generated by the wind and/or solar systems can be sold into the power grid.

There are also battery systems that can store this cheap power to be used during higher rate periods. Nevertheless, we have to be judicious in investing in these resources; there are areas where the average daily sunlight or average wind speed is not enough to justify the investment.

This discussion of ways to thoughtfully use renewable energy at the plant leads us to the materials at the plant. In the final installment of this series next month, we’ll look at the different categories of materials in use at any asphalt plant and their sustainability as well as profitability.

Malcolm Swanson is the vice president, innovative products, for Astec Inc., Chattanooga.