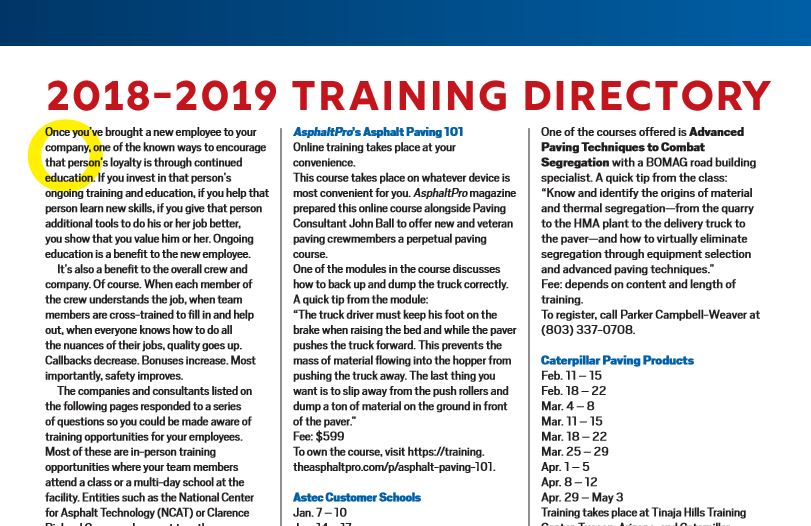

2018-2019 Training Directory

BY Sandy Lender

Once you’ve brought a new employee to your company, one of the known ways to encourage that person’s loyalty is through continued education. If you invest in that person’s ongoing training and education, if you help that person learn new skills, if you give that person additional tools to do his or her job better, you show that you value him or her. Ongoing education is a benefit to the new employee.

It’s also a benefit to the overall crew and company. Of course. When each member of the crew understands the job, when team members are cross-trained to fill in and help out, when everyone knows how to do all the nuances of their jobs, quality goes up. Callbacks decrease. Bonuses increase. Most importantly, safety improves.

The companies and consultants listed on the following pages responded to a series of questions so you could be made aware of training opportunities for your employees. Most of these are in-person training opportunities where your team members attend a class or a multi-day school at the facility. Entities such as the National Center for Asphalt Technology (NCAT) or Clarence Richard Company have put together programs that take place at your facility. Consultants such as John Ball of Top Quality Paving not only go to your facility, they spend time in the field with your crew. Notice that many courses include an “electronic” element whereby attendees take home a thumb drive or gain access to a website with additional training videos before, during and/or after the class(es).

It may be a bit self-serving, but I want to highlight the online training course from AsphaltPro as well. We teamed up with John Ball to fine-tune a paving course full of videos, pictures and instruction that introduces the basics for new employees. It’s one of those courses you can download and keep forever, so each time you bring a new worker to the team, you can have him or her “take the course” before going out to the field. Of course it doesn’t delve into the intricacies of each and every paver or roller ever made, so you will still want to check with your OEM if you have a specific question related to a certain machine model. The good news is you’ll have a great foundation from which to start.

Check out the entities who have taken the time to share their training opportunities with you in the next few pages and build your skill set from the offerings to follow.

AsphaltPro’s Asphalt Paving 101

Online training takes place at your convenience.

This course takes place on whatever device is most convenient for you. AsphaltPro magazine prepared this online course alongside Paving Consultant John Ball to offer new and veteran paving crewmembers a perpetual paving course.

One of the modules in the course discusses how to back up and dump the truck correctly.

A quick tip from the module: “The truck driver must keep his foot on the brake when raising the bed and while the paver pushes the truck forward. This prevents the mass of material flowing into the hopper from pushing the truck away. The last thing you want is to slip away from the push rollers and dump a ton of material on the ground in front of the paver.”

Fee: $599

To own the course, enroll here.

Astec Customer Schools

- Jan. 7 – 10

- Jan. 14 – 17

- Jan. 21 – 24

- Jan. 28 – 31

- Feb. 4 – 7

- Feb. 11 – 14

This school takes place in Chattanooga. Astec Customer Schools teach hands-on plant operation, maintenance and advanced troubleshooting techniques to fix problems fast.

Meals, snacks and special dinner receptions are included.

Fee: $1,250

To register, call (423) 827-1899 or visit www.astecinc.com.

BOMAG Training Academy

Dates are available upon request.

This school takes place in Ridgeway, South Carolina. BOMAG tailors the training sessions to meet the customer’s needs. The classes are designed to improve the customer’s understanding on the fundamentals of and tips necessary to improve the overall quality output for soil and asphalt compaction, road rehabilitation, and asphalt paving. No online training courses are available at this time.

Depending on the length of training, meals may be provided.

One of the courses offered is Advanced Paving Techniques to Combat Segregation with a BOMAG road building specialist.

A quick tip from the class: “Know and identify the origins of material and thermal segregation—from the quarry to the HMA plant to the delivery truck to the paver—and how to virtually eliminate segregation through equipment selection and advanced paving techniques.”

Fee: depends on content and length of training.

To register, call Parker Campbell-Weaver at (803) 337-0708.

Caterpillar Paving Products

- Feb. 11 – 15

- Feb. 18 – 22

- Mar. 4 – 8

- Mar. 11 – 15

- Mar. 18 – 22

- Mar. 25 – 29

- Apr. 1 – 5

- Apr. 8 – 12

- Apr. 29 – May 3

Training takes place at Tinaja Hills Training Center, Tucson, Arizona, and Caterpillar Customer Sales & Learning Center, Maple Grove, Minnesota. The goal of Paving Operations Training is to review the principles of asphalt paving, practice good paving techniques following the guidelines of Paving by the Numbers and prepare the attendee to conduct similar training within his or her organization.

Tuition includes training materials, lunch and morning/afternoon refreshments.

One of the courses offered is Paving Operations Training with instructor Ron Wilson.

A quick tip from class: “Paving By the Numbers—Make sure you understand the principals of paving and how they relate to Paving By the Numbers.”

Fee: $3,100 per attendee

To register, contact Wojack_denice_c@cat.com at (763) 315-5510.

CEI Service School Seminar

- Dec. 10-13, 2018

- Jan. 14-17

- Jan. 21-24

- Feb. 4-7

- Feb. 11-14

This school takes place in Albuquerque, New Mexico. Topics include CEI heater preventive maintenance, safety controls testing procedures, thermal fluid application and filtration, reading electrical schematics, damper control adjustment, combustion analysis, and more.

Course manuals are provided in digital format.

Hotel, meals and transportation from hotel to training facility are included in the tuition.

Fee: $1,125

Clarence Richard Co. School

Training takes place at the students’ availability.

The Online Asphalt Plant Operation Workshop takes place online. The course teaches people new to the industry as well as veterans with many years of experience. The course includes downloadable templates, spreadsheets, calculators, etc., to help keep their plants running safely and efficiently. Participants receive a certificate of achievement as well as a two-way report card that provides their scores/improvement as well as an opportunity to provide feedback on the program.

Fee: $995 (plus $195 for optional manual)

Classroom Plant Workshop

Feb. 19 – 20, 2019

This course takes place in DesMoines, Iowa.

The course includes manuals, meals and happy hours.

Fee: $995

Classroom Electro-Mechanical

Feb. 21, 2019

This course takes place in DesMoines, Iowa.

The course includes manuals, meal and happy hour.

Fee: $595

To register, visit www.clarencerichard.com

Controls Group USA

Dates are to be confirmed.

This school takes place in Elgin, Illinois. It teaches students to understand and appreciate the methodology and practical requirements of carrying out a dynamic modulus test on asphalt mixtures correctly.

Lunch, one night hotel accommodation and training manual are provided. Attendees receive a company certificate of attendance.

One of the courses offered is Dynamic Modulus Testing on Asphalt Mixtures with instructor Phil Blankenship. A quick tip from class: “Establish the correct tuning parameters for your specific material to be tested.”

Fee: $1,200

To register, contact info@controls-usa.com.

Gencor Advanced Training School

- Jan. 14 – 18, 2019

- Jan. 21 – 25, 2019

- Feb. 18 – 22, 2019

- Feb. 25 – Mar. 1, 2019

This school takes place in Orlando. “At Gencor, we believe that properly trained maintainers, operators and superintendents are best equipped to respond quickly, thereby minimizing downtime and returning the plant to production….Our training is built on the same course materials used to teach our own technicians creating the optimum learning experience for asphalt producers. Those who go through our training programs benefit from real experience with real equipment.” Attendees receive an electronic device with all training materials, and can access all training videos online.

Lunches, snacks and two dinners are provided.

One of the courses offered is Baghouse with a Gencor instructor.

A quick tip from class: You can take steps to keep your baghouse running at peak efficiency. “Preheating is critical. Thorough preheating only takes about 20 minutes, though it is frequently overlooked in the haste of starting the plant each day. Proper preheating can extend the life of bags as well as the sidewalls, tube sheet, hopper and ductwork. Allowing moisture to develop in these areas even briefly can promote premature rusting, as well as costly blinding of the bags.”

Fee: $1,050 per person

To register, visit Gencor on www.gencor.com/training before Dec. 14, 2018.

Honeywell Asphalt Product Maintenance Seminar

- Jan. 15 – 17

- Jan. 22 – 24

- Jan. 29 – 31

This school takes place in Muncie, Indiana. It teaches students to reduce downtime, improve equipment life, maximize combustion system efficiency, and increase knowledge and understanding of Hauck combustion and control equipment.

Breakfast, lunch and dinner are provided on days one and two; breakfast and lunch on day three; reception on Monday evening. Attendees receive a certificate of attendance.

One of the courses offered is BCS3000M Control Panel with instructor Patrick Horn. During the class, Horn performs the actuator calibration procedure using a visual display of the actuator slidewire and voltmeter, which allows students to see the change in signal as the actuator is driven open.

Fee: $1,100

To register, contact Patrick.Horn@honeywell.com.

Infrared Repair Process Training

Dates are scheduled individually.

This training from KM International takes place in North Branch, Michigan. The goal of the training is to provide customers the knowledge and expertise to be successful using KM International infrared equipment. KM International provides instructional and demonstration videos via its YouTube channel and company website.

Lunch is provided. Attendees also receive a KM International hat and t-shirt.

Attendees receive a certificate verifying completion of factory-recommended training.

One of the courses offered is Infrared Repair Process Training with instructors Cliff Cameron, KM president, and Bryan Burke, CEO.

A quick tip from the class: “Follow the exact 12-step infrared repair process.”

Fee: none

KPI-JCI and Astec Mobile Screens PRO Training

Classes occur throughout the year.

Classes take place in Yankton, South Dakota; Eugene, Oregon; and Sterling, Illinois. Having powerful equipment is only part of what it takes to run a profitable aggregate operation. The people you trust to run the equipment, and the skills and training they possess, are equally important. The PRO Training service programs are designed to educate you and your team about the effective operation and maintenance of your equipment. Networking opportunities with the experts from KPI-JCI and Astec Mobile Screens, as well as tours of the manufacturing facilities, are available to PRO Training attendees. Free online PRO Training courses are available prior to attending the factory schools, which ensures attendees will be able to spend more hands-on time outside the classroom. Online courses can be found at kpijci.com.mrooms.net.

Breakfast and lunch are served daily and a hosted dinner and event will be offered on one of the nights following the training.

Attendees receive a PRO Training certificate of completion.

Service Application School

Dec. 4 – 6, 2018

One of the courses offered is the PRO Training Service Application School with instructors Terry Haas, Erik Schmidt and Louis DeMay. A quick tip from class:

“Feed size and gradation can greatly affect production in KPI-JCI and Astec Mobile Screens machines.”

Fee: $399 regular rate ($299 early bird)

To register, visit here.

NCAT On-site Training Workshops

Week-long on-site training occurs as requested.

On-site training occurs at your location. It provides technical background to help engineers improve pavement performance.

Participants typically earn 3.6 CEU or 36 PDH credits.

The course offered is an on-site training workshop with NCAT Engineers Don Watson and Mike Heitzman.

A quick tip from class: “Asphalt mixtures are defined by measured weight proportion of materials, but the critical components of asphalt mixture are based on computed volumetric properties that rely on correctly measured material specific gravity values.”

Fee: varies

To register, visit here.

RMAEC

Courses are offered throughout the year.

The courses take place in Centennial, Colorado. The Rocky Mountain Asphalt Education Center (RMAEC) was founded in 1996 as the Education and Certification Arm for the Colorado Asphalt Pavement Association (CAPA). In addition to facilitating the Laboratory for Certification of Asphalt Technicians (LabCAT) program, the RMAEC offers educational seminars for city and county agencies, contractors, and consultants.

Most seminars are held in the RMAEC classroom; however, there are opportunities to customize employee training days at your company location. The LabCAT program was developed to increase the proficiency of asphalt technicians, improve the reliability of QC/QA testing, increase the quality of asphalt paving materials purchased by owner-agencies, and respond to the Federal-Aid projects. The program is a partnership between the Colorado Department of Transportation (CDOT), CAPA and the Federal Highway Administration (FHWA). A joint board of directors consisting of CAPA, CDOT, FHWA and industry representatives provides direction to the program. The center has an extensive webinar program.

Tuition includes continental service in the morning, and most sessions include lunch. The center provides a continuing education letter for all attendees who request it.

One of the courses offered is Introduction to PC/OA Testing with instructor Cindy Rutkoski.

Fee: varies

To register, visit here.

Roadtec’s Paving Professional Workshop

Jan. 7 – 8

Jan. 9 – 10

Jan. 14 – 15

Jan. 16 – 17

This school takes place in Chattanooga. A team of experienced professionals from industry leading companies provide thorough classroom and hands-on instruction to help each attendee learn as much as possible about the complete process of paving. The presentations are available for 10 days after the final class.

Two breakfasts, two lunches, one dinner and snack breaks are included.

One of the courses at the school is Surface Preparation/Tack and Asphalt Emulsion with instruction Brian Horner of E.D. Etnyre. A quick tip from the class:

“Check calibration of the truck. Use mats for longitudinal rate test by weighting the mats or using the bucket test by weighting the buckets.”

Fee: $250

To register, visit here.

Schwarze Training Academy

- Oct. 16 – 17, 2018

- Nov. 13 – 16, 2018

- Dec. 4 – 7, 2018

This school takes place in Huntsville, Alabama. Sweeper technicians will receive the advanced training in areas such as electrical system diagnosis, control system diagnosis, noise, vibration, harshness diagnosis and repair. Upon completion of the course, students receive a USB drive with training materials, reference materials, schematics and product manuals.

The program includes classroom sessions, maintenance and troubleshooting, hands-on instructions, product walk-around, factory tour, catered lunch and refreshments during the course. Technicians receive an official certificate from Schwarze Industries.

One of the courses offered is Mechanical Broom Sweepers Factory Training with instructor Costas Cordonis.

A quick tip from the class: One way to enhance sweeper performance is to get the correct sweeper setting for the specific sweeping condition.

Fee: $150

To register, contact mhendricks@schwarze.com.

Top Quality Paving and Training

Training takes place at the contractors’ availability.

Industry consultant John Ball teaches in the classroom and in the field at your facility and on your project site. The training teaches people new to the industry as well as veterans with many years of experience the basics of paving and compaction, as well as how to train the trainers among your workers.

Fee: determined by location

To check availability, contact tqpaving@yahoo.com.

TransTech Density Clinic

Dates are handled individually.

This school takes place in Latham, New York. It teaches students to properly use the company’s density gauges. The school includes online or electronic offerings such as YouTube training videos.

Depending on the length of training, lunch may be provided. Attendees receive a certificate from TransTech Systems.

One of the courses offered is PQI Density Training with instructor Ron Berube. A quick tip from class: “Most important, call our office if you have any questions while using the equipment.”

Fee: none

To register, call TransTech Systems at (800) 724-6306.

Troxler Learning Center

Dates are available throughout the year.

In-person, hands-on, non-nuclear and nuclear gauge training takes place at Research Triangle Park, North Carolina. The classes allow you to earn certifications and gain new skills/refresh old ones with knowledgeable instructors. Online courses provide unlimited flexibility to train when it suits your schedule.

The Nuclear Gauge Safety Training plus Hazmat online course is accepted for certification by most state agencies. Students receive the following certifications after completing the in-person classes and online courses: Hazmat certification/recertification; Nuclear gauge operator safety certification; and Radiation safety officer certification.

One of the courses offered is Nuclear Gauge Safety Training plus Hazmat with instructors Robyn Myers and Michael Dixon.

A quick tip from class: “To prevent measurement errors, be sure to position the gauge’s handle properly in the notch and ensure that the gauge is in contact with the material being tested.”

Fees: in-person classes range from $89 to $395; online courses range from $29 to $295

To register, visit the Training menu on www.troxlerlabs.com.

Dig into training concepts with these three articles: